Method for preparing nano cuprous oxide in glycerol and n-dibutyl adipate mixed liquid system

A technology of n-dibutyl adipate and nano cuprous oxide, applied in copper oxide/copper hydroxide, nanotechnology for material and surface science, nanotechnology, etc., to achieve uniform size, easy availability of raw materials and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

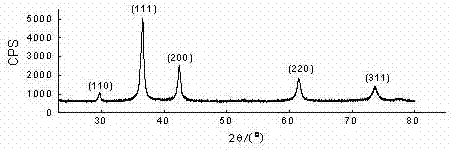

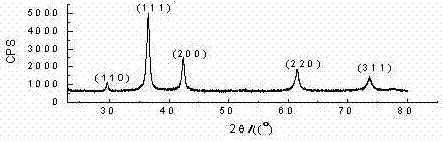

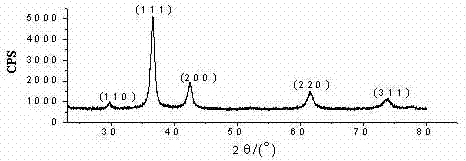

Image

Examples

Embodiment 1

[0024] 1) Put 60mL of glycerol and n-dibutyl adipate mixture (volume ratio 2::1) into a three-necked flask, add 2.50g of copper formate solid powder, and simultaneously add cetyltrimethylammonium bromide (CTMAB) 0.500 g, the mixture was made into a suspension under constant stirring.

[0025] 2) Slowly increase the temperature of the reaction mixture during rapid stirring. When the temperature rises to 390K, control the temperature to no longer rise, continue to stir and react at 390K for 80 minutes, and naturally cool to room temperature to obtain nano-cuprous oxide containing of the suspension.

[0026] 3) Dilute the suspension obtained in step 2) with 60 mL of absolute ethanol or acetone, filter under reduced pressure, and then wash with appropriate amount of absolute ethanol or acetone for 4 times.

[0027] 4) Put the cleaned cuprous oxide powder into a vacuum drying oven, and vacuum-dry for 480 minutes at a temperature of 350K to obtain red nano-sized cuprous oxide powde...

Embodiment 2

[0030] 1) Put 60mL of glycerol and n-dibutyl adipate mixture (volume ratio 2::1) into a three-necked flask, add 2.50g of copper formate solid powder, and add sodium dodecylbenzenesulfonate (SDBS ) 0.500g, make the mixture into a suspension under continuous stirring.

[0031] 2) Slowly increase the temperature of the reaction mixture during rapid stirring. When the temperature rises to 400K, control the temperature to no longer rise, continue to stir and react at 400K for 90 minutes, and naturally cool to room temperature to obtain nano-cuprous oxide containing of the suspension.

[0032] 3) Dilute the suspension obtained in step 2) with 50 mL of absolute ethanol or acetone, filter under reduced pressure, and then repeatedly wash with appropriate amount of absolute ethanol or acetone for 3 times.

[0033] 4) Put the cleaned cuprous oxide powder into a vacuum drying oven, and vacuum-dry it at a temperature of 350K for 480 minutes to obtain red nano cuprous oxide powder crystals...

Embodiment 3

[0036] 1) Put 60mL of glycerin and n-dibutyl adipate mixture (volume ratio 2::1) into a three-necked flask, add 2.50g of copper formate solid powder, and add 0.400g of polyvinylpyrrolidone (PVP) at the same time, The mixture was made into a suspension with constant stirring.

[0037] 2) Slowly raise the temperature of the reaction mixture during rapid stirring. When the temperature rises to 405K, control the temperature to no longer rise, continue to stir and react for 95 minutes, and naturally cool to room temperature to obtain a suspension containing nano-cuprous oxide.

[0038] 3) Dilute the suspension obtained in step 2) with 60 mL of absolute ethanol or acetone, filter under reduced pressure, and then wash with appropriate amount of absolute ethanol or acetone for 4 times.

[0039] 4) Put the cleaned cuprous oxide powder into a vacuum drying oven, and vacuum-dry it at a temperature of 350K for 480 minutes to obtain red nano cuprous oxide powder crystals.

[0040] image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com