Purifying system for removing VOC (Volatile Organic Compounds) out of industrial waste gas

A technology of industrial waste gas and purification system, which is applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc. It can solve the problems of unsatisfactory treatment effect, large floor area and high construction cost, so as to improve the degree of regeneration and adsorption capacity , reduced consumption, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

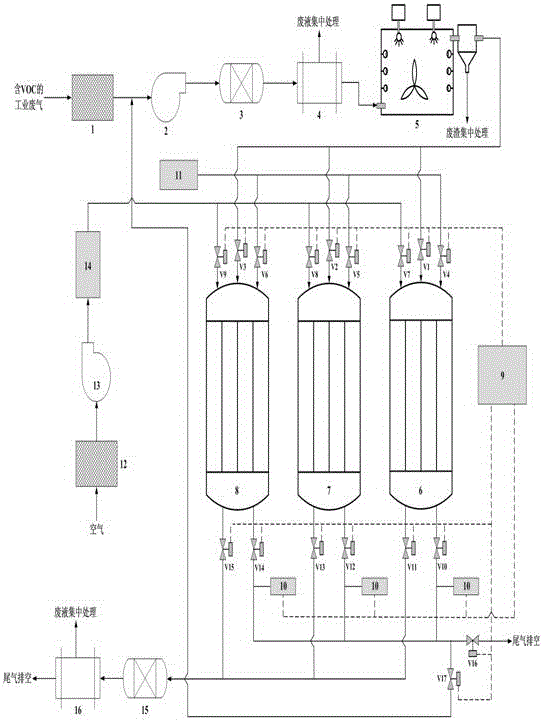

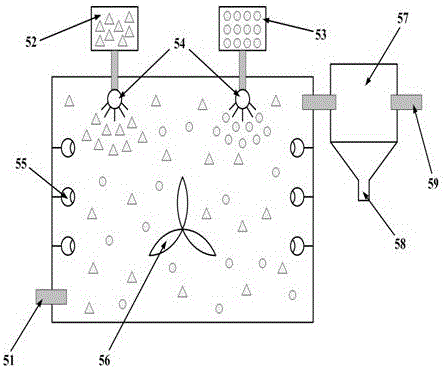

[0036] Such as figure 1 The shown purification system for removing VOC in industrial waste gas includes filter A1, induced draft fan 2, condenser A3, gas-liquid separator A4, iron-cobalt photocatalyst salinization effect dehalogenation reactor 5, adsorption tower A6, adsorption Tower B7, adsorption tower C8, PLC automatic control unit 9, VOC gas detector 10, steam generator 11, filter B12, air compressor 13, dryer 14, condenser B15, gas-liquid separator B16 and 17 sets of program control Valves V1~V17, etc. Among them, the industrial waste gas containing VOC enters the system through the gas pipeline, firstly filters out the acidic and alkaline gas components and particulate matter in the waste gas through the filter A1, and then provides kinetic energy for the waste gas through the induced draft fan 2 , the exhaust gas is sent to the condenser A3, where the temperature of the exhaust gas entering the adsorption tower is reduced to ensure the optimal adsorption temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com