System of using iron-carbon-Fenton pretreatment-UBF-A/O for treating dye waste water and method thereof

A technology for iron carbon Fenton and dye wastewater, which is applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc. Processing power, the effect of increasing the speed of biochemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

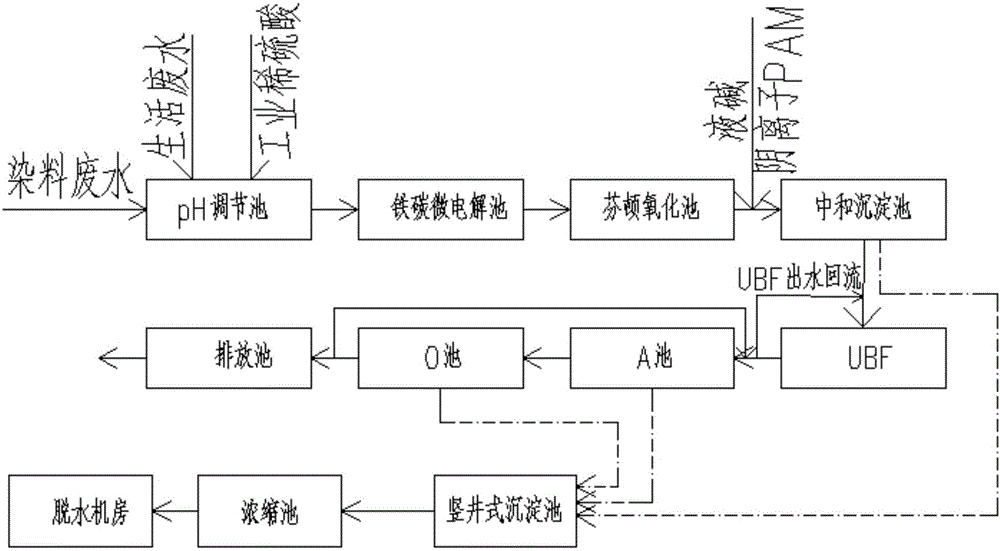

[0042] Such as figure 1 As shown, a Fenton oxidation-UBF anaerobic treatment-A / O system and method for treating dye wastewater in this embodiment is applied to a wastewater treatment station for dye wastewater in Binhai Chemical Industry Park, Jiangsu Province.

[0043] A dye wastewater treatment station in Jiangsu Binhai Chemical Industry Park includes pH adjustment tank, iron-carbon micro-electrolysis tank, Fenton oxidation tank, neutralization sedimentation tank, UBF reaction tank, A tank, O tank, vertical flow sedimentation tank and discharge tank.

[0044] The size of the pH adjustment pool is length × width × height = 8 × 7.8 × 5m, V = 312m 3 , effective volume 260m 3 , the residence time is 4h, the pH adjustment pool adopts the bottom 75°pH adjustment pool to flow water to the iron-carbon micro-electrolysis pool; the iron-carbon micro-electrolysis pool is composed of two iron-carbon micro-electrolysis pools connected in series, and the effective volume of each pool is ...

Embodiment 2

[0051] A system for treating dye wastewater using iron-carbon micro-electrolysis Fenton pretreatment-UBF-A / O in this embodiment:

[0052] After dye production wastewater is regulated by domestic sewage, the salt content needs to be reduced to 2200mg / L to prevent adverse effects on the microorganisms in the subsequent biochemical tank. The pH value of the wastewater adjusted by the pH adjustment tank is 2; the iron, carbon and catalyst in the iron carbon ball packing The mass ratio is 8.5:2:1, the porosity of high temperature sintering at 1000°C reaches 58%, and the specific surface area is 1.8 square meters per gram; the concentration of hydrogen peroxide in the Fenton oxidation tank is 15000ppm; the COD concentration of the pH adjustment tank in this embodiment reaches 2880mg / L, the COD of the effluent is stable to 1370mg / L. Compared with the traditional ozone process and wet oxidation process, the iron-carbon-Fenton technology not only achieves the removal of COD, but also r...

Embodiment 3

[0054] A system for treating dye wastewater using iron-carbon micro-electrolysis Fenton pretreatment-UBF-A / O in this embodiment:

[0055] The reflux ratio of the UBF system is 200%, and the rising flow rate of the UBF is controlled at 70m 3 / h, the rising flow rate is controlled at 0.7m / h, and the organic load is controlled below 5kg; the reflux ratio of the nitrifying liquid in the O tank is 200%, and the sludge reflux ratio of the vertical flow sedimentation tank is 150%.

[0056] In this embodiment, the COD concentration of UBF influent reaches 1370 mg / L, and the COD concentration of UBF effluent is 1070 mg / L.

[0057] The hydraulic retention time of the A / O tank is 3h and 4h respectively, the residence time of the vertical flow sedimentation tank is 18h, the sludge return ratio is 150%, the COD concentration of the influent is 1070mg / L, and the COD of the vertical sedimentation tank is 420mg / L . Compared with the traditional UASB reactor, the UBF with filter layer and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com