Aerobic pressurizing high-temperature fermentation tank for solid organic matter

A solid organic matter, high-temperature fermentation technology, applied in the field of fermentation tanks, can solve the problems of difficult control of fermentation temperature and process, high collection and transportation costs, and difficulty in waste gas treatment, and achieve the effects of shortening the fermentation cycle, small footprint, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with example, accompanying drawing, the present invention will be further described, and implementation of the present invention is not limited to following embodiment.

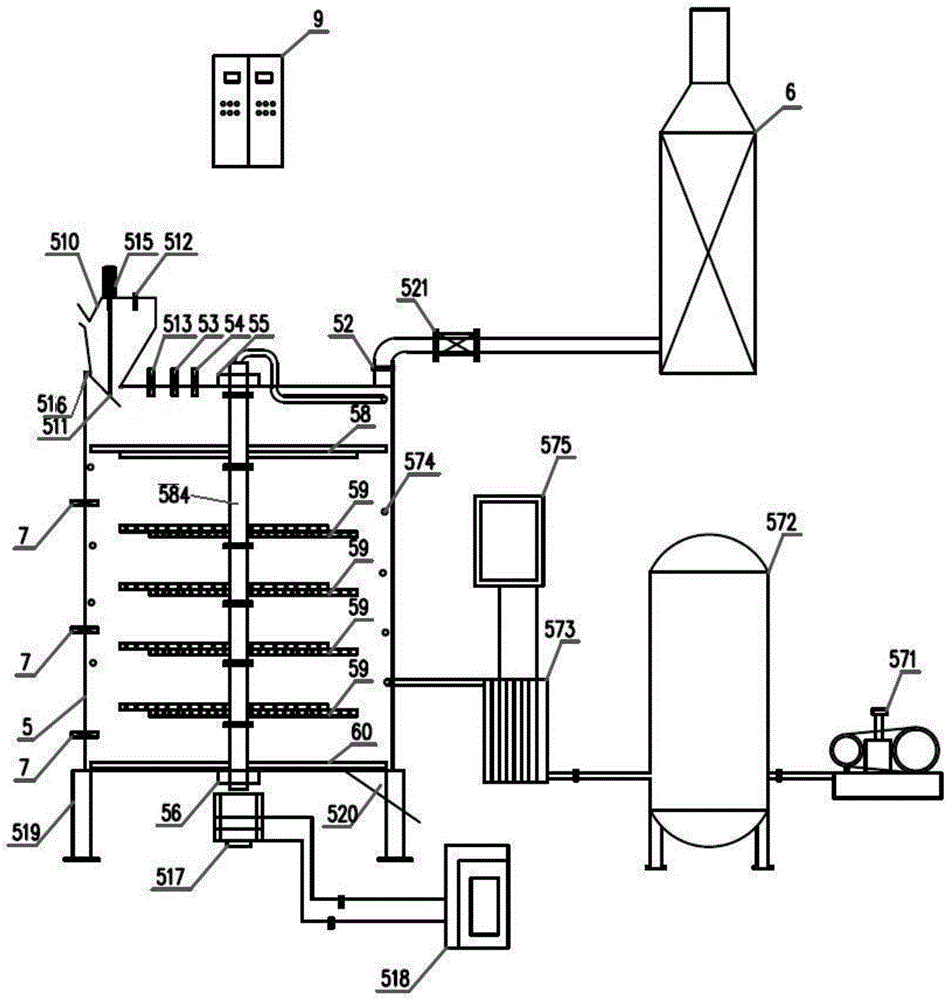

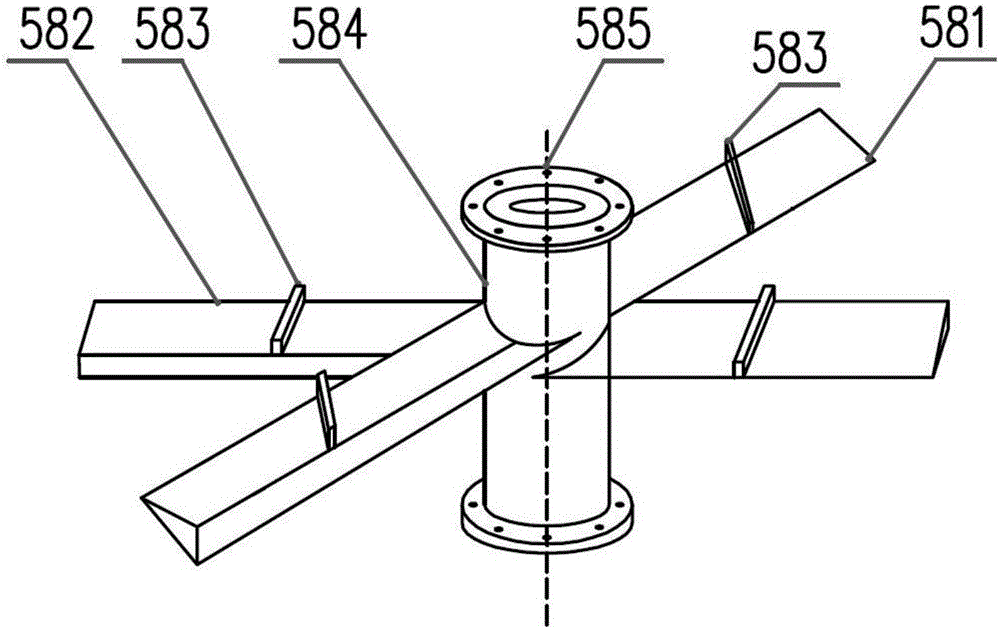

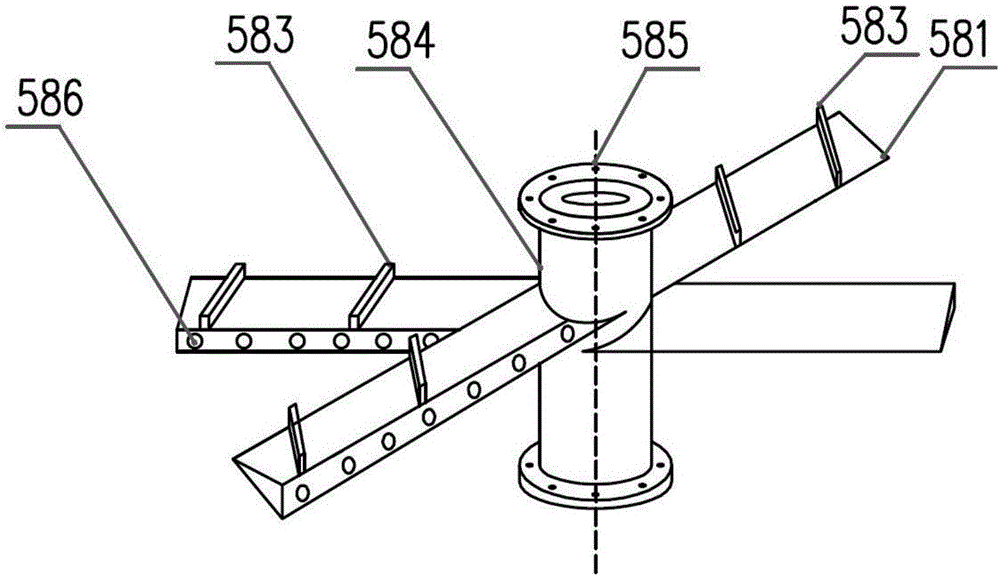

[0032] Such as figure 1 As shown, an aerobic pressurized high-temperature fermentation tank for solid organic matter, the main body is made of stainless steel or carbon steel with anti-corrosion treatment, including a tank body 5, a feeding system, a fixed shaft 584, a material distribution mechanism 58, a material transfer mechanism 59, and a discharge mechanism 60, the vent port 52, the discharge port 520 and the internal heat exchanger 574;

[0033] The feeding system is located at the top of the tank body 5, including a storage bin 510 and a feed hatch 511, and the feed hatch 511 is located at the bottom of the storage bin 510 for controlling the entry of materials from the storage bin 510 into the tank body 5; Feed hatch 511 is provided with gasket around, and the hatch plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com