Preparing method and application of calcium carbonate dispersing agent for PVC sectional material

A technology of calcium carbonate and dispersant, which is applied in the field of calcium carbonate dispersant to achieve the effect of increasing filling amount, high dispersion efficiency and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

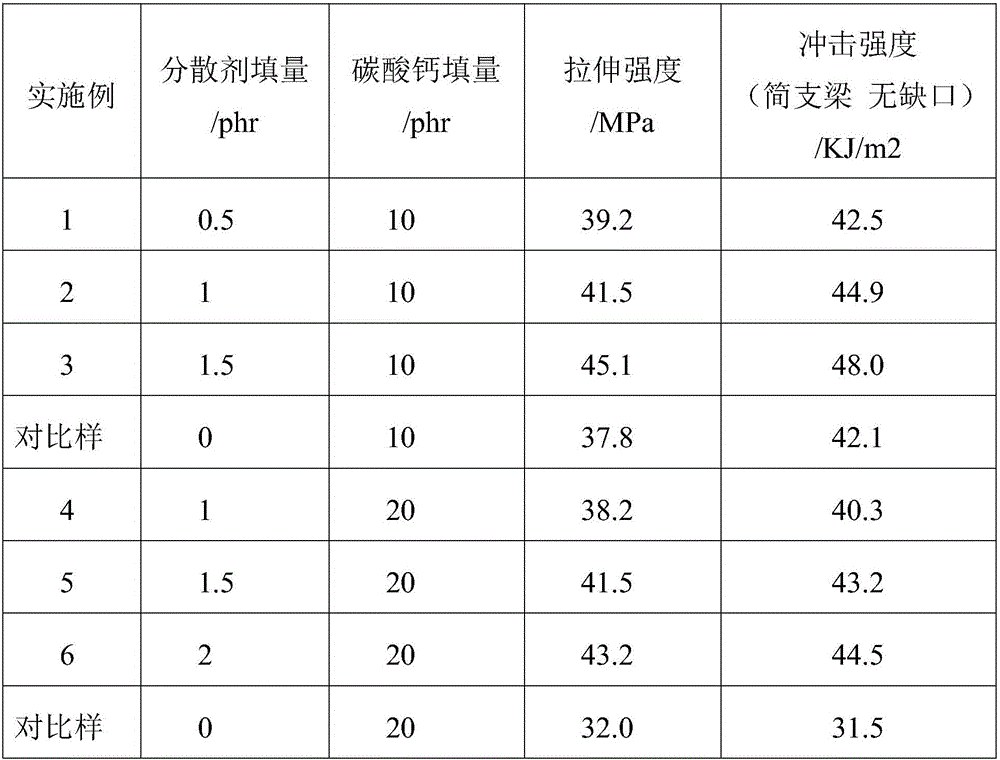

Examples

Embodiment 1

[0019] In a 1000ml four-necked flask equipped with an electric stirrer, a spherical condenser and a thermometer, add 20g of allyl polyoxyethylene ether, 2g of sodium lauryl sulfate, 2g of OP-10 and 220g of water, then stir at a high speed For 30 minutes, heat to 90°C, slowly add dropwise a mixed solution of 120g methyl methacrylate and 20g butyl acrylate, 100g weight concentration of 20% methacrylic acid and 0.5% mercaptoacetic acid using a peristaltic pump under stirring The aqueous solution of composition, 50g weight concentration is the ammonium persulfate aqueous solution of 5%. The dropwise addition time is 3 hours. After the dropwise addition, keep at 95°C for 2 hours, and finally cool to room temperature, adjust the pH value to 7-8 with 30% sodium hydroxide by weight concentration, and use centrifugal spray drying to spray powder to obtain the product .

Embodiment 2

[0021] In a four-necked flask equipped with an electric stirrer, a spherical condenser, and a 1000ml thermometer, add 20g of allyl polyoxyethylene ether, 2g of sodium lauryl sulfate, 1g of OP-10 and 220g of water, then stir at high speed for 30 Minutes, heated to 90°C, and slowly added dropwise a mixed solution of 100g styrene and 25g butyl acrylate while stirring, and an aqueous solution composed of 20% acrylic acid and 0.5% thioglycolic acid with a weight concentration of 100g, 50g weight Concentration of 5% ammonium persulfate in water. The dropwise addition time is 3 hours. After the dropwise addition, keep at 95°C for 2 hours, and finally cool to room temperature, adjust the pH value to 7-8 with 30% sodium hydroxide by weight concentration, and use centrifugal spray drying to spray powder to obtain the product .

Embodiment 3

[0023] In a four-necked flask equipped with an electric stirrer, a spherical condenser, and a 1000ml thermometer, add 20g allyl polyoxyethylene ether, 2g sodium lauryl sulfate, 2g OP-10, 36g methyl methacrylate, 6g of butyl acrylate, 6g of methacrylic acid and 220g of water, then stirred at high speed for 30 minutes, heated to 90°C, slowly added 15g of ammonium persulfate aqueous solution with a weight concentration of 5% under stirring, and kept at 90°C after the solution turned blue After stirring for 30 minutes, the mixed solution of 84g methyl methacrylate and 14g butyl acrylate was slowly added dropwise using a peristaltic pump, the aqueous solution of 20% methacrylic acid and 0.5% mercaptoacetic acid in 70g weight concentration and the 35g weight concentration 5% ammonium persulfate in water. The dropping time is 3 hours. After the dropping is completed, keep at 95°C for 2 hours, and finally cool to room temperature, adjust the pH value to 7-8 with 30% sodium hydroxide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com