Preparation method and application of environment-friendly, low-viscosity and high-strength epoxy grouting material

A grouting material with low viscosity technology, which is applied in the field of environmentally friendly, low-viscosity, high-strength epoxy-based grouting materials. It can solve the problems of groutability limitations, large shrinkage of cured products, and decreased physical properties, and achieve excellent mechanical properties of cured products. Stable curing volume and simple slurry ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

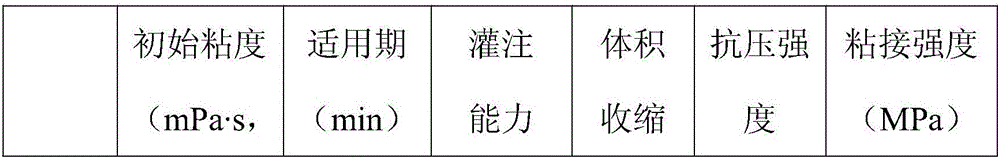

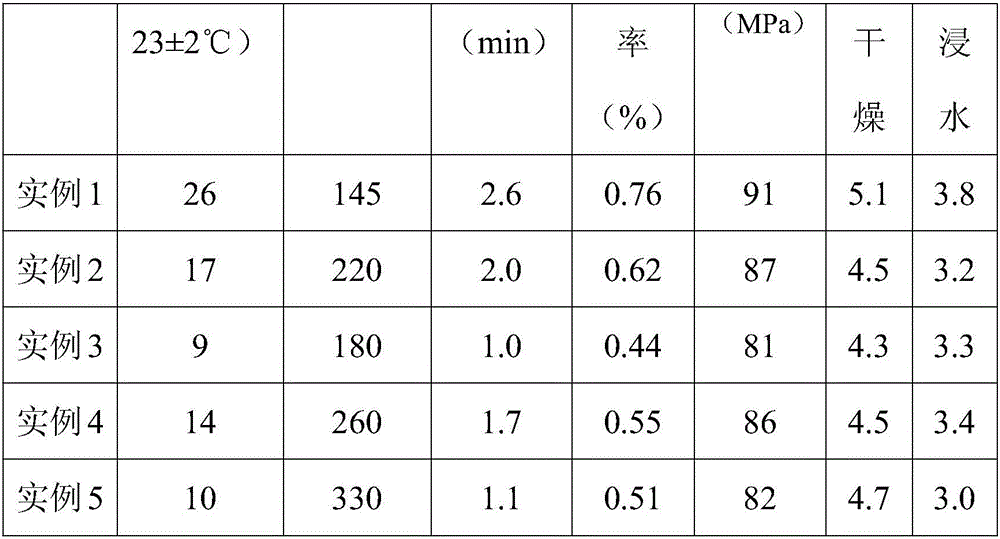

Examples

Embodiment 1

[0033] The invention provides a method for preparing an environment-friendly high-strength epoxy-based chemical grouting material, comprising the following steps:

[0034] 1) Mix 50-80 parts of epoxy resin and 20-50 parts of cross-linking diluent to obtain liquid A;

[0035] 2) Mix 5-10 parts of curing agent and 1-5 parts of accelerator to obtain liquid B;

[0036] 3) 1 to 10 parts of initiator constitute component C alone;

[0037] 4) When using, mix and stir liquid A and liquid B evenly, then add component C, and stir well to obtain an environmentally friendly high-strength epoxy-based chemical grouting material.

Embodiment 2

[0039] On the basis of embodiment 1, the epoxy resin described in step one is bisphenol A type epoxy resin, and described bisphenol A type epoxy resin is E-35 type epoxy resin, E-44 type epoxy resin One or at least two of resin or E-51 type epoxy resin.

[0040] The cross-linking diluent in step one is one or at least two of methyl methacrylate, butyl acrylate or hydroxybutyl acrylate.

[0041] The curing agent described in the second step is one or at least two of diethylenetriamine, triethylenetetramine or tetraethylenepentamine.

[0042] The accelerator described in the second step is one of N,N dimethylaniline, ethylimidazole or dimethylimidazole.

[0043] The initiator described in step 3 is prepared by the following steps: mix the peroxide and the inert solvent according to the mass ratio (50-80): (20-50), after standing for 24 hours, obtain the initiator through sufficient dehydration .

[0044] Described peroxide is one or at least two in organic peroxide; Described...

Embodiment 3

[0047] An environmentally friendly, low-viscosity, high-strength epoxy-based grouting material is prepared by the following method:

[0048] 1) Preparation of initiator (component C): 65 parts by mass of benzoyl peroxide and 50 parts by mass of dibutyl phthalate were evenly mixed, and after standing for 24 hours, fully dehydrated to obtain the initiator.

[0049] 2) Preparation of environmentally friendly low-viscosity high-strength epoxy grouting material:

[0050] Liquid A: 75 parts by mass of E-51 type epoxy resin and 25 parts by mass of methyl methacrylate are uniformly mixed to obtain;

[0051] Liquid B: obtained by uniformly mixing 10 parts by mass of diethylenetriamine and 4 parts by mass of N,N dimethylaniline;

[0052]When in use, mix liquid A, liquid B and 8 parts by mass of initiator (component C) uniformly to obtain a non-toxic, low-viscosity, high-strength epoxy grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com