Method for preparing plant fiber-based foamed thermoplastic masterbatch

A technology of plant fiber and foaming heat, which is applied in the field of preparation of natural plant fiber-based foaming thermoplastic masterbatch, can solve the problems of degradation of lignocellulosic materials, affect product quality, and decrease in mechanical strength, and achieve the improvement of mechanical properties and Improvement of plasticizing efficiency and hot-melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

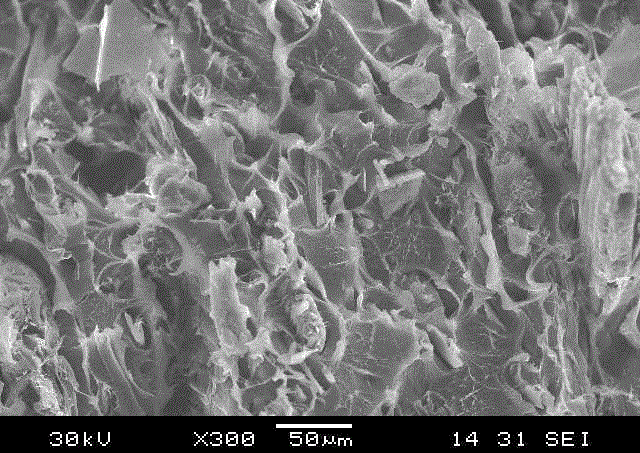

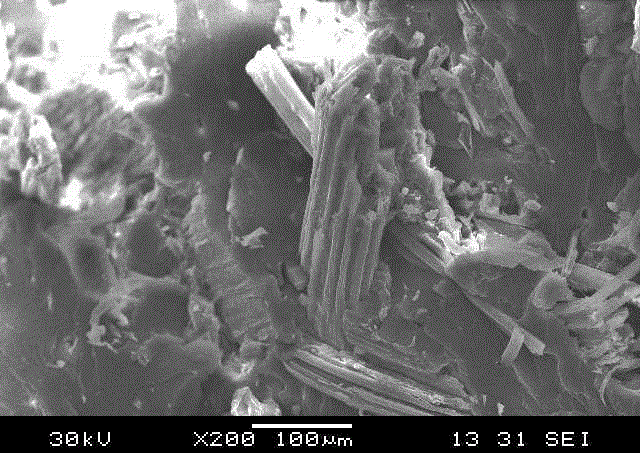

Image

Examples

Embodiment 1

[0035] Step 1), mix 100g of dried plant fiber (rice straw crushed to 20 meshes in this example) and 200ml of lye swelling agent (sodium hydroxide solution with a concentration of 5%), and place at -10°C Immerse in the environment for 45 minutes, then move into an ultrasonic reactor with an ultrasonic frequency of 22kHz, the working pressure is 2Mpa (in the specific implementation, the working pressure can be selected in the range of 2-6MPa according to the actual situation), the stirring speed is 100rpm, and the ultrasonic reaction is 5min (the specific implementation During the process, the reaction time can also be selected according to the actual situation (5-40min); Drain the natural plant fiber powder and dry it at 103±2°C to obtain alkalized plant fiber powder (NaO-Wd);

[0036] Put 100g NaO-Wd and 100g modified plasticizer (obtained by mixing lauroyl chloride, benzyl chloride and maleic anhydride with a mass ratio of 5:4:1 in sequence) in a double-layer glass reactor, an...

Embodiment 2

[0045] Step 1) Mix 100g of dry and crushed wheat straw powder to 80 mesh with 250ml of 30% potassium hydroxide solution evenly, place it at -10°C for 45min, and then move it into an ultrasonic reactor with an ultrasonic frequency of 22kHz and a working pressure of 6MPa, stirring Rotate at 100rpm, sonicate for 40 minutes, drain the natural plant fiber powder, and dry it at 103±2°C to obtain alkalized plant fiber powder (NaO-Wd);

[0046] Put 100g NaO-Wd and 250g modified plasticizer (obtained by mixing lauroyl chloride, benzyl chloride and maleic anhydride with a mass ratio of 5:2:3 in turn) in a double-layer glass reactor. ℃ / min, heat up to 100°C, react for 90 minutes, cool down to 45°C naturally, filter with suction and wash the filter residue alternately with water and ethanol until the eluate is neutral, place the filter residue at 73°C for 24 hours in vacuum to obtain Plasticized natural plant fiber powder (ArO-Wd).

[0047] Step 2), 300g ArO-Wd, 100g polypropylene, 2.5g ...

Embodiment 3

[0054] Adjust step 2) in Example 2 to 400g ArO-Wd, 100g polypropylene, 2.5g foaming agent (azodicarbonamide 1-2: sodium bicarbonate: zinc oxide = 1:1:0.5), 3g calcium Zinc composite stabilizer, 5g titanium dioxide, 5g nano-calcium carbonate, and 5g coloring agent were placed in a high-speed mixer, heated at 100°C for 8 minutes, stirred evenly, cooled to 45°C, and discharged into the feed truck to obtain a Bubble thermoplastic compound. Other steps are the same as in Example 2), and the temperature setting of the extruder is shown in Table 1. The prepared natural plant fiber-based foamed thermoplastic masterbatch is marked as C.

[0055] Examples 2 and 3 prepared natural plant fiber-based foamed thermoplastic masterbatches, using a φ65 / 132 conical twin-screw extruder, heating temperature and other main parameters are shown in Table 1.

[0056] The performance testing data of natural plant fiber-based foamed thermoplastic masterbatch are shown in Table 2:

[0057] Table 2 Melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com