Improved method and system for producing methane by using two-phase anaerobic digestion process

An anaerobic digestion and methane technology, applied in biochemical equipment and methods, gas production bioreactors, specific-purpose bioreactors/fermenters, etc., can solve the problem of reducing reaction efficiency, threats to surrounding environment safety, and reducing system energy Recovery efficiency and other issues, to achieve the effect of improving methane recovery rate, improving energy recovery efficiency, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

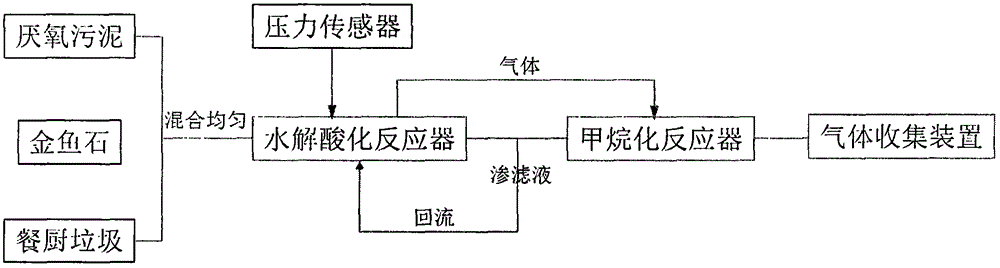

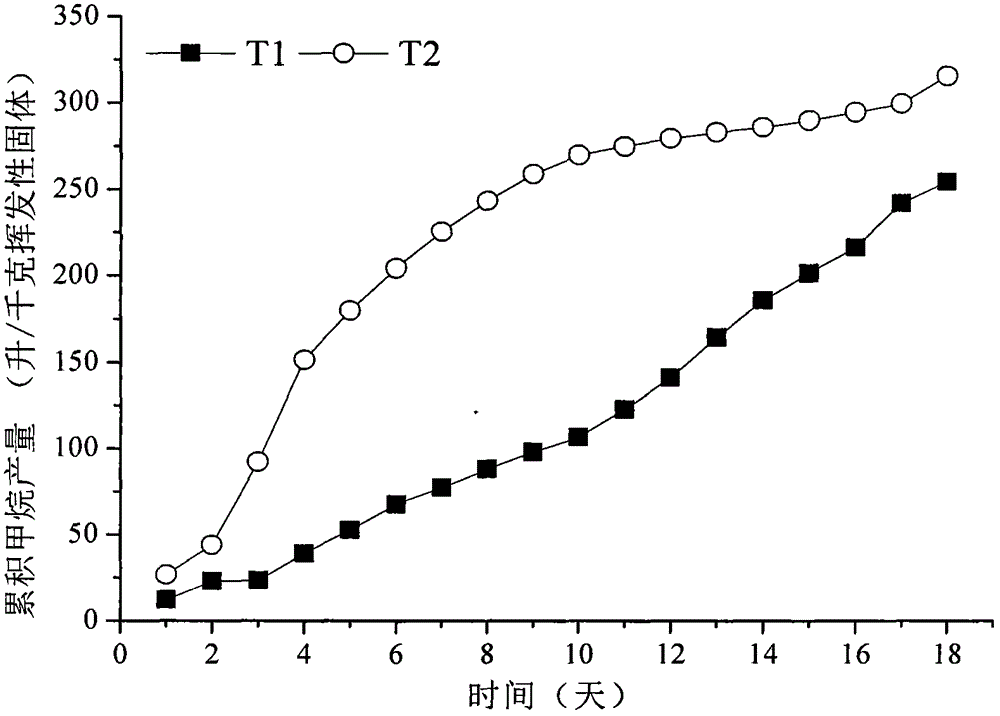

[0061] See attached figure 1 : Before the start of the experiment, the sludge in the methanation reactor was domesticated with artificially prepared glucose wastewater; at the same time, hydrogen was passed into the reactor at a rate of 3.2 liters of hydrogen per liter of reactor per day to enhance the activity of hydrogen-type methanogens , when the content of methane in the generated biogas is stable at about 85% (fluctuation is less than 5%) and the COD removal rate of the effluent reaches 85-95%, the domestication is over and it will be used; in order to better understand the acidification reaction under the design conditions To determine the effects of headspace pressure control and non-control on methane production and COD, this experiment set up a traditional acidification reactor coupled with a methanation reactor without regulating the headspace pressure of the hydrolysis phase as a control. The acidification reactor is a percolation bed reactor with a working volume ...

Embodiment 2

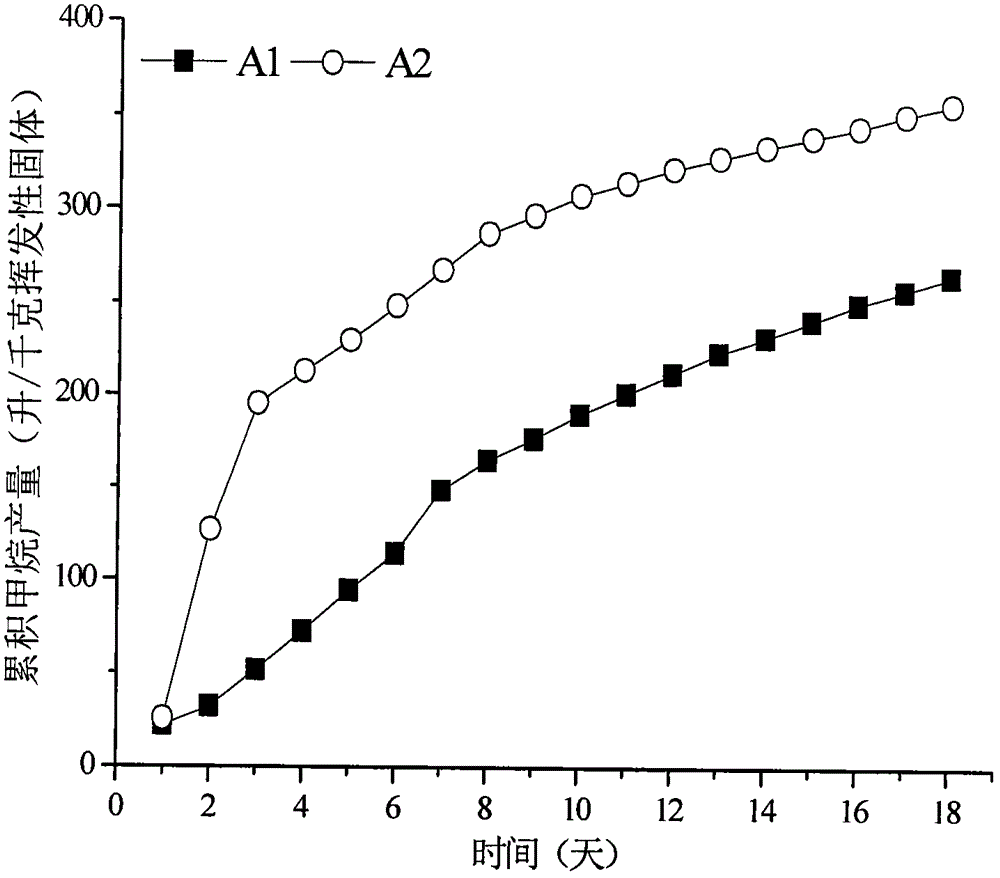

[0070] Before the start of the experiment, the sludge in the methanation reactor was domesticated with artificially prepared glucose wastewater and hydrogen; at the same time, hydrogen was passed into the reactor at a rate of 3.2 liters of hydrogen per liter of reactor per day to strengthen the growth of hydrogen-type methanogens. Activity, when the methane content in the generated biogas is stable at about 85% (fluctuation is less than 5%) and the COD removal rate of the effluent reaches 85-95%, the domestication is over and it is ready for use; in order to better understand the acidification under the design conditions The influence of reactor headspace pressure control and non-control on methane production and COD generation, this experiment set up the treatment of traditional acidification reactor coupling methanation reactor without regulating the headspace pressure of hydrolysis phase as a control. The acidification reactor is a percolation bed reactor with a working volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com