Preparation method of millimeter-scale single-layer single crystal graphene

A single crystal graphene, millimeter-scale technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as reducing electron mobility, thermal conductivity, reducing graphene-related properties and application value , to achieve the effect of simple preparation process and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

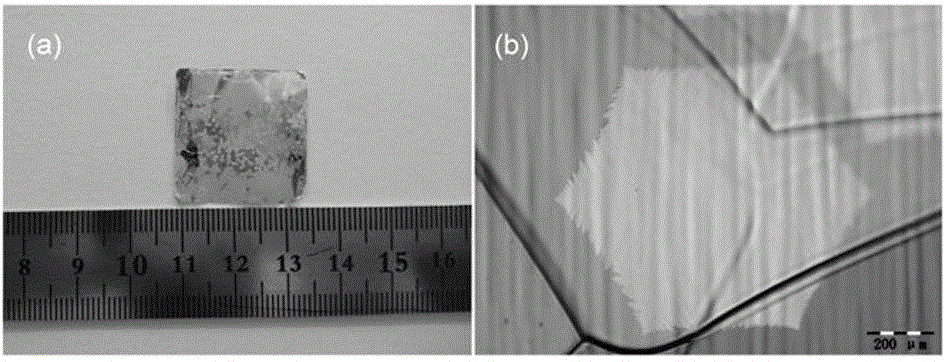

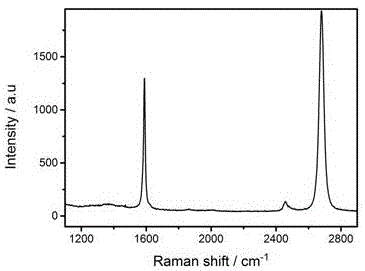

[0019] A method for preparing millimeter-scale single-layer single-crystal graphene, the specific steps are:

[0020] 1) Cut the copper foil as the growth substrate into a rectangular shape with a size of 2.5cm*2.5cm;

[0021] 2) Put the cut copper foil into dilute hydrochloric acid for ultrasonic cleaning, then transfer it to acetone solution for ultrasonic cleaning, and dry it with nitrogen after cleaning;

[0022] 3) Put the copper foil into the quartz tube of the tube furnace, pass in 300 sccm of Ar and heat up to 1070°C;

[0023] 4) Pass 300sccmAr and 50sccmH at 1070°C 2 And annealed at high temperature for 4 hours;

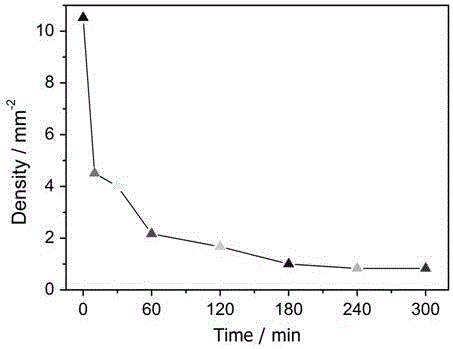

[0024] 5) After high temperature annealing, 0.5 sccm of CH was introduced at 1070°C 4 and 50sccmH 2 Grow graphene for 2 hours;

[0025] 6) After the growth is over, turn on the tube furnace to cool down the sample rapidly and inject 300sccmAr and 4sccmH 2 , and the samples were taken out after cooling down to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com