Garbage gasification fuel gas and steam turbine combined power generation system of humid air turbine

A steam turbine and combined power generation technology, which is applied to steam generation, steam engine devices, steam generation devices, etc., can solve the problems of easy dust accumulation, large supply volume, and large flue gas volume, and achieve less waste residue and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

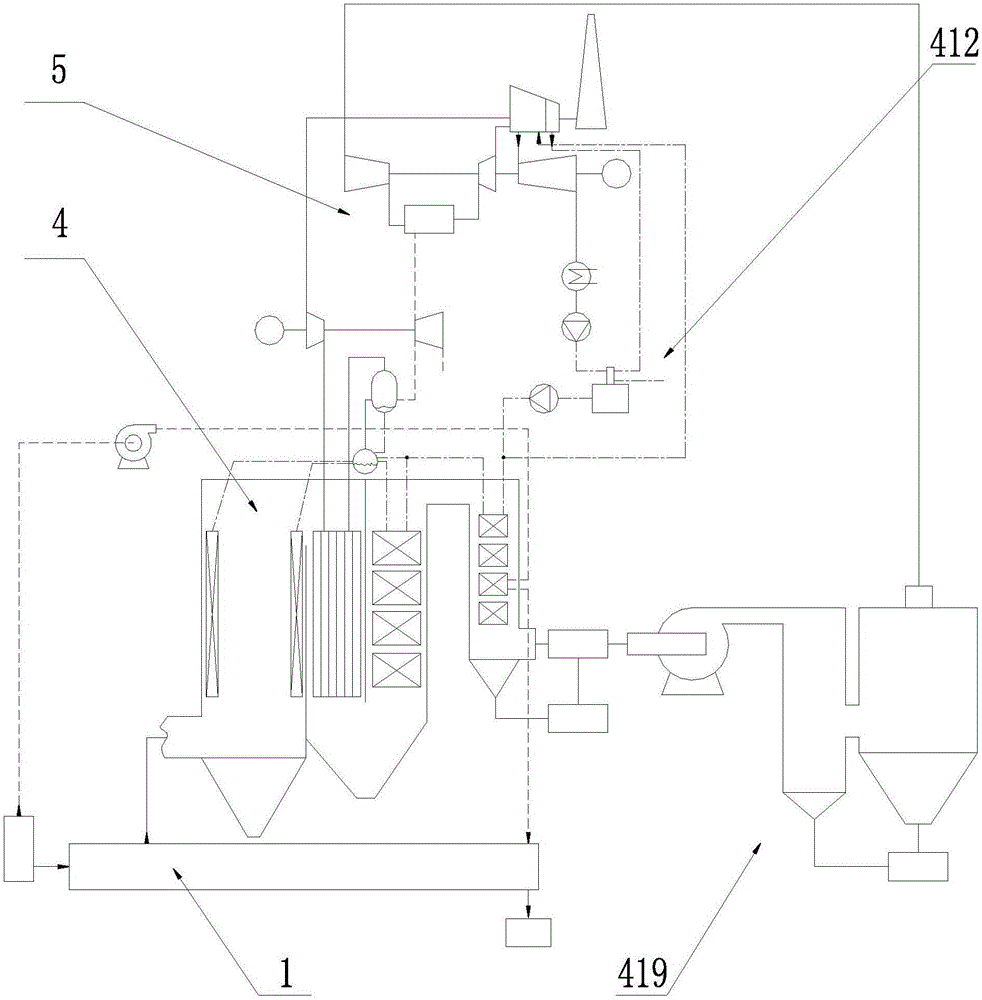

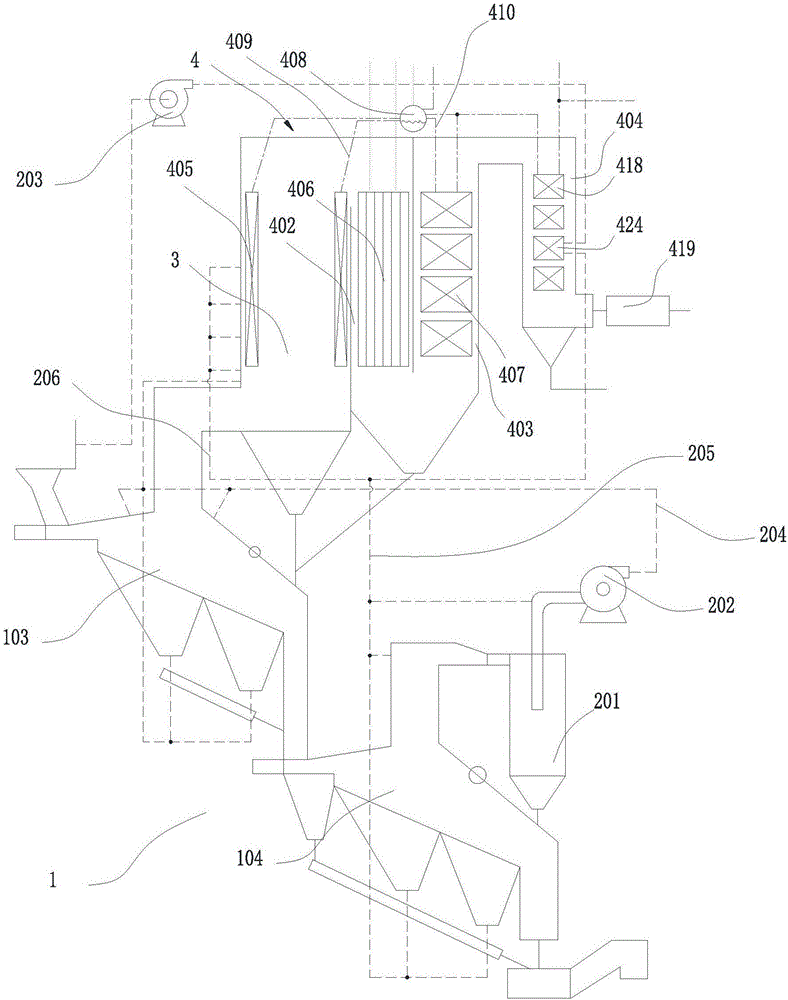

[0045] see figure 1 , which is a preferred embodiment of a waste gasification gas and steam turbine combined power generation system of a wet air turbine, including a waste gasification incineration system, a boiler system, and a power generation system 5, and the boiler system has a steam drum 408 , Superheater 406.

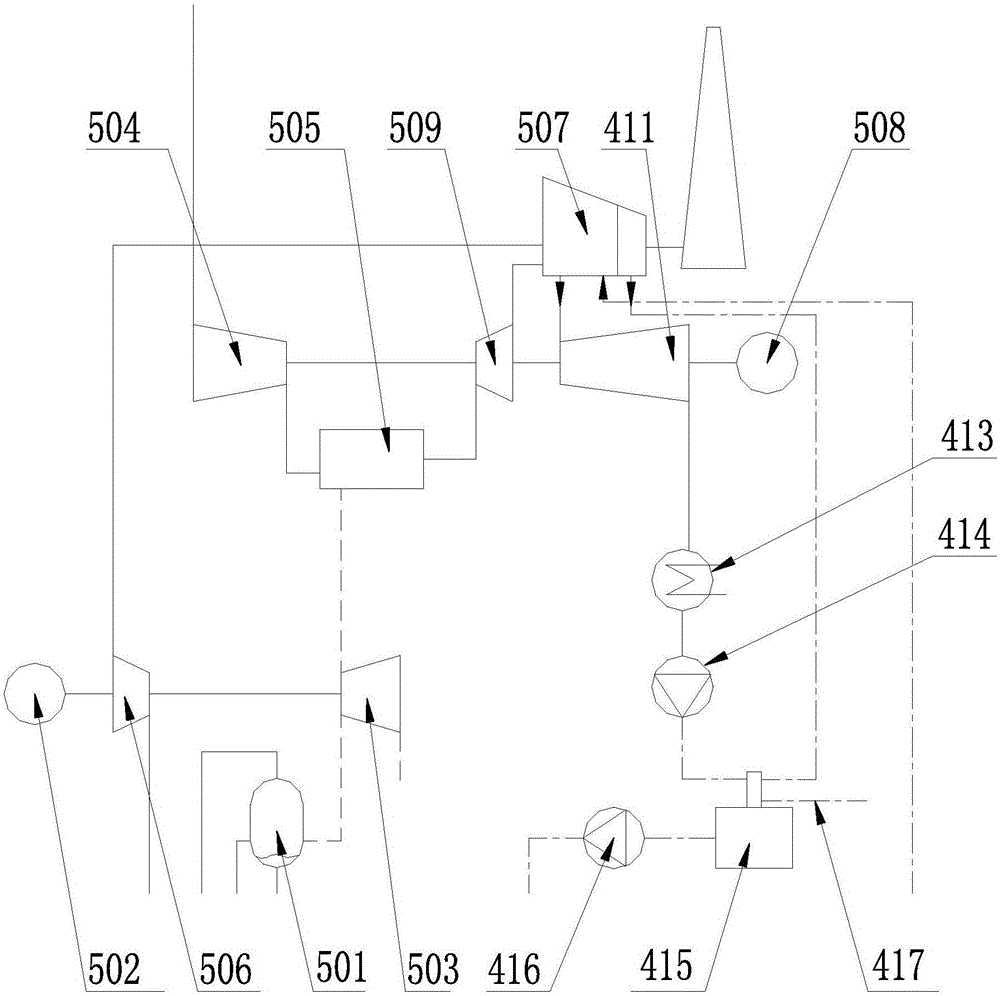

[0046] see figure 2 , the power generation system includes a mixer 501, an air compressor 503, a synthetic flue gas compressor 504, a synthetic flue gas combustion chamber 505, a turbine a506, a turbine b509, a steam turbine, a generator a502, a generator b508, a waste heat boiler 507 and feed water The input system, further, the air compressor 503, the turbine a506, and the generator a502 are sequentially powered and rotated synchronously; the synthetic smoke gas compressor 504, the turbine b509, the steam turbine, and the generator b508 are sequentially powered and synchronized turn.

[0047] The side wall of the mixer 501 is provided with a first inlet an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap