Solid lithium ion-super-capacitor hybrid battery

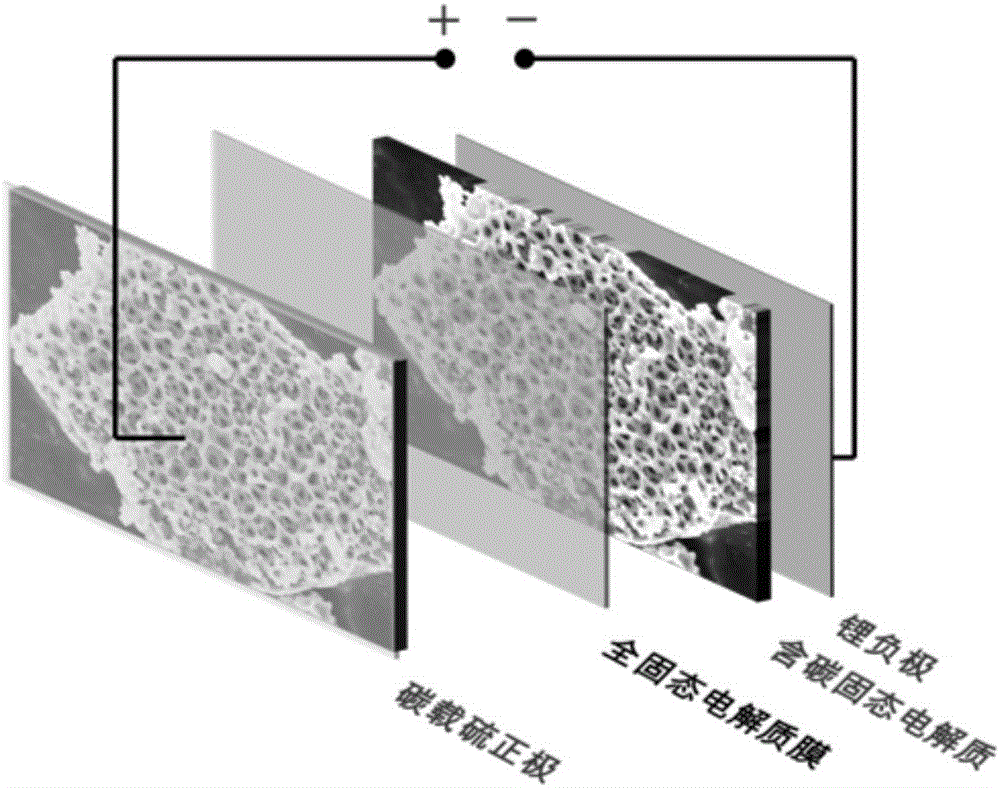

A lithium-ion battery and supercapacitor technology, applied in the field of electrochemical energy, can solve the problem of no contribution to the capacity of lithium-sulfur batteries, and achieve excellent mechanical and puncture resistance, improved stability, and high energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Elemental sulfur-loaded carbon nanotubes are used as the positive electrode active material, Super-P is used as the conductive agent, acrylic resin (PAA) is used as the binder, and N-methyl-pyrrolidone (NMP) is used as the solvent, according to the mass ratio of 8:1:1 After being stirred into a uniform slurry, it is coated on an aluminum foil, and metal lithium is used as the active material of the negative electrode. A polyoxyethylene solid electrolyte membrane, specifically a solid electrolyte membrane containing LiI and a mixture containing LiTFSI and porous activated carbon (its preparation process: dissolve 0.08g of MIL-53(Al) and 0.23g of LII in 9mL of acetonitrile , stirred for 2 hours, added 0.4g PEO, stirred for 24 hours, volatilized the solvent at room temperature for 6 hours, and then volatilized at 80°C for 24 hours to obtain a polymer electrolyte membrane. In the same procedure, 0.23g LiTFSI and 0.23g porous activated carbon were replaced by LiI ) as a comp...

Embodiment 2

[0040] Use elemental sulfur-loaded graphene as the positive electrode active material, Super-P as the conductive agent, acrylic resin (PAA) as the binder, and N-methyl-pyrrolidone (NMP) as the solvent, and stir according to the mass ratio of 8:1:1 After forming a uniform slurry, it is coated on an aluminum foil, and metal lithium is used as the active material of the negative electrode. Polyoxyethylene is used as a solid electrolyte membrane, specifically, a solid electrolyte membrane containing LiCl is used in combination with a mixture containing LiTFSI and graphene (the preparation process: 0.08g of MIL-53(Al) and 0.23g of LII are dissolved in 9mL of In acetonitrile, stir for 2 hours, add 0.4g PEO, stir for 24 hours, volatilize the solvent at room temperature for 6 hours, and then volatilize at 80°C for 24 hours to obtain a polymer electrolyte membrane. In the same step, replace 0.23g LiTFSI and 0.46g graphene LiCl) as a composite solid electrolyte for batteries, and then a...

Embodiment 3

[0042] Elemental sulfur-loaded carbon nanotubes are used as the positive active material, carbon nanotubes and metal lithium are used as the negative active material, Super-P is used as the conductive agent, acrylic resin (PAA) is used as the binder, and N-methyl-pyrrolidone ( NMP) as a solvent, stirred into a uniform slurry according to the mass ratio of 8:1:1, and then coated on aluminum foil and copper foil respectively to make positive electrode sheets and negative electrode sheets. Polyoxyethylene solid electrolyte membrane (preparation process: dissolve 0.08g of MIL-53(Al) and 0.23g of LITFSI in 9mL of acetonitrile, stir for 2h, add 0.4g of PEO, stir for 24h, and evaporate the solvent at room temperature 6h, and then volatilized at 80°C for 24h to obtain a polymer electrolyte membrane.) As a separator of a hybrid battery and a lithium-ion conducting material, then drop 1-2 drops of TEABF on the surface of the positive electrode material and the electrolyte membrane 4 / AN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com