Ion-doped perovskite solar cell and manufacturing method thereof

A technology of solar cells and ion doping, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc. It can solve the problems of large grain size electron transmission obstacles, reduced photoelectric conversion efficiency of batteries, and unstable light output power. Achieve the effect of increasing electron mobility, improving battery efficiency, and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1, preparing a doping solution of lithium iodide (anhydrous LiI with a purity of 99%) and dimethyl sulfoxide, the concentration of which is 0.4mol / L, for doping the original solution of the perovskite precursor solution, The concentration of doping is 1%. Preferably, the lithium iodide in this embodiment is anhydrous LiI with a purity of 99%.

[0028] First, a layer of dense titanium dioxide film (100 nanometers) is coated on the conductive glass layer by spin coating or spraying by sol-gel method; after treatment at 450°C, titanium tetrachloride treatment is performed on the dense layer of titanium dioxide, and it is sintered for later use. Preferably, the thickness of the dense titanium dioxide film in this embodiment is preferably 100 nanometers.

[0029] Then methyl iodide and lead chloride were dissolved in N,N-dimethylformamide at a molar ratio of 3:1 to 1:1 to prepare a stock solution of perovskite precursor.

[0030] Then lithium iodide was dissolved i...

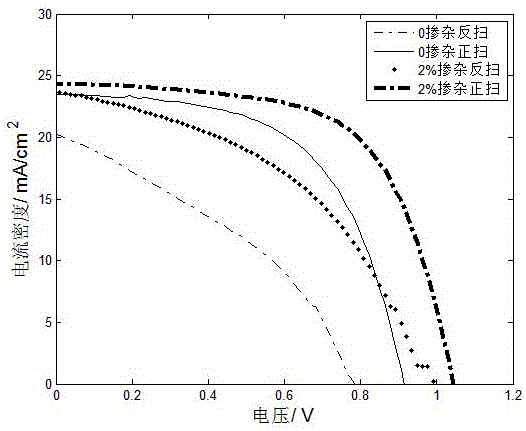

Embodiment 2

[0035] Example 2, preparing a doping solution of lithium iodide (anhydrous LiI with a purity of 99%) and dimethyl sulfoxide, the concentration of which is 0.4mol / L, for doping the original solution of the perovskite precursor solution, The concentration of doping is 2%. Preferably, the lithium iodide in this embodiment is anhydrous LiI with a purity of 99%.

[0036] First, a layer of dense titanium dioxide film is coated on the conductive glass layer by spin coating or spraying by sol-gel method; after treatment at 450°C, titanium tetrachloride treatment is performed on the dense layer of titanium dioxide, and it is sintered for later use. Preferably, the thickness of the dense titanium dioxide film in this embodiment is preferably 50 nanometers.

[0037] Then methyl iodide and lead chloride were dissolved in N,N-dimethylformamide at a molar ratio of 3:1 to 1:1 to prepare a stock solution of perovskite precursor.

[0038] Then dissolve lithium iodide in dimethyl sulfoxide, a...

Embodiment 3

[0044] Example 3, preparing a doping solution of lithium iodide (anhydrous LiI with a purity of 99%) and dimethyl sulfoxide, the concentration of which is 0.4mol / L, for doping the original solution of the perovskite precursor solution, The concentration of doping is 5%. Lithium iodide in this embodiment is anhydrous LiI with a purity of 99%.

[0045] First, a layer of dense titanium dioxide film is coated on the conductive glass layer by spin coating or spraying by sol-gel method; after treatment at 450°C, titanium tetrachloride treatment is performed on the dense layer of titanium dioxide, and it is sintered for later use. The thickness of the dense titanium dioxide film in this embodiment is preferably 50 nanometers.

[0046] Then methyl iodide and lead chloride were dissolved in N,N-dimethylformamide at a molar ratio of 3:1 to 1:1 to prepare a stock solution of perovskite precursor.

[0047] Then dissolve lithium iodide in dimethyl sulfoxide, and drop the prepared doping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com