A kind of anode material for biomass alkaline fuel cell and preparation method thereof

A fuel cell and anode material technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of viologen compounds that are harmful to the ecological environment, expensive metal catalysts, complex graphene preparation processes, etc. The effect of improving catalytic reaction efficiency and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

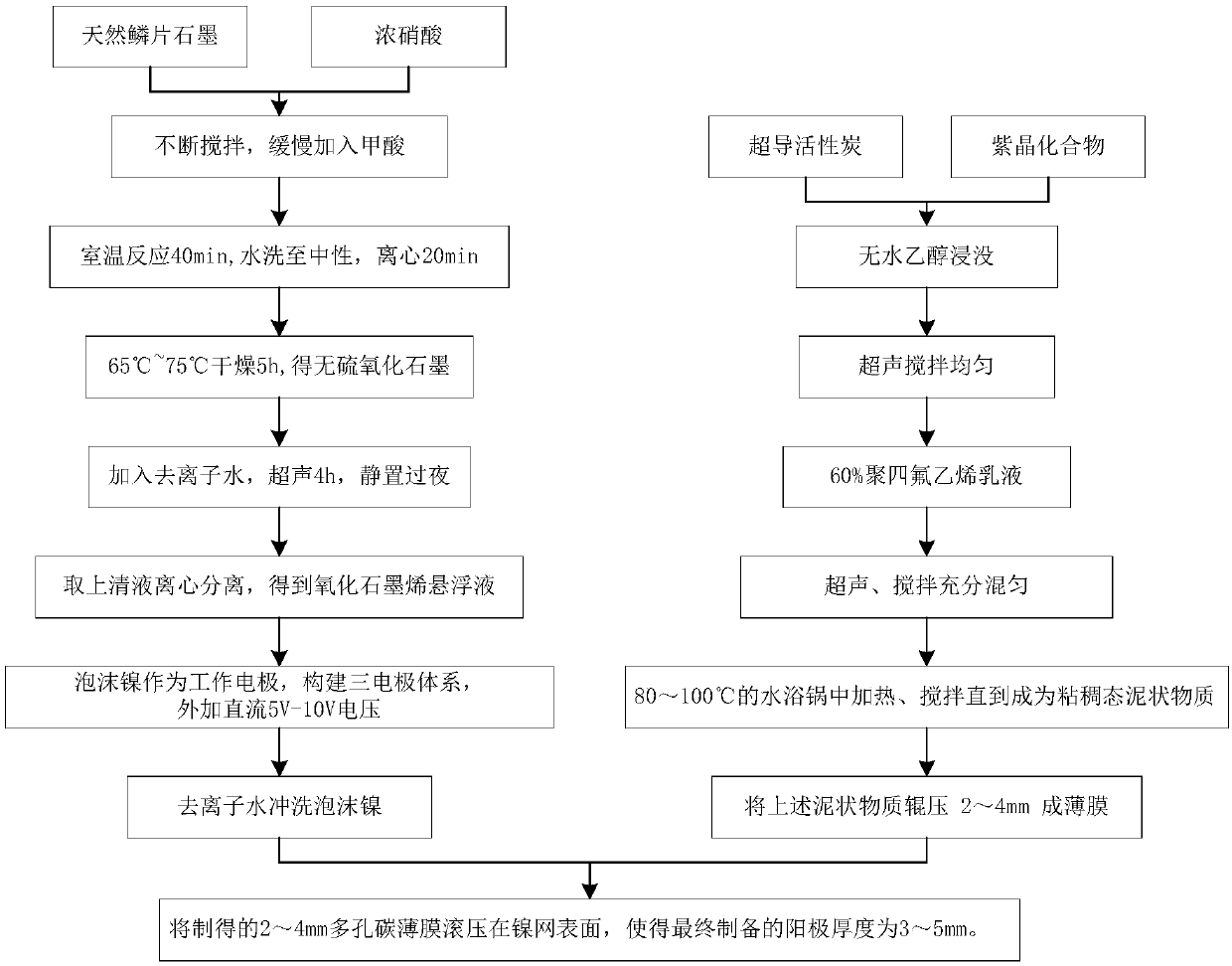

[0033] (1) Add concentrated nitric acid (analytical pure) to 325 mesh natural flake graphite according to the mass ratio of 1:1, stir to mix the two evenly, after the natural flake graphite is oxidized by concentrated nitric acid for 20 minutes, under the condition of constant stirring Next, add formic acid (analytically pure), make the ratio of formic acid and natural flake graphite be 4:5, and react 40min at room temperature;

[0034] (2) washing and suction-filtering the mixture obtained in (1) until the pH is 5-7, and drying the obtained water-washed product at 70° C. for 5 hours to obtain sulfur-free graphite oxide;

[0035] (3) Take sulfur-free graphite oxide and ultrasonically disperse it in deionized water. After ultrasonic stripping for 4 hours, a dispersion of 1.25 g / l is obtained, which is allowed to stand overnight. The supernatant is centrifuged at 10,000 r / min for 20 minutes to obtain the upper layer The liquid is graphene oxide suspension;

[0036] (4) Take an ...

Embodiment 2

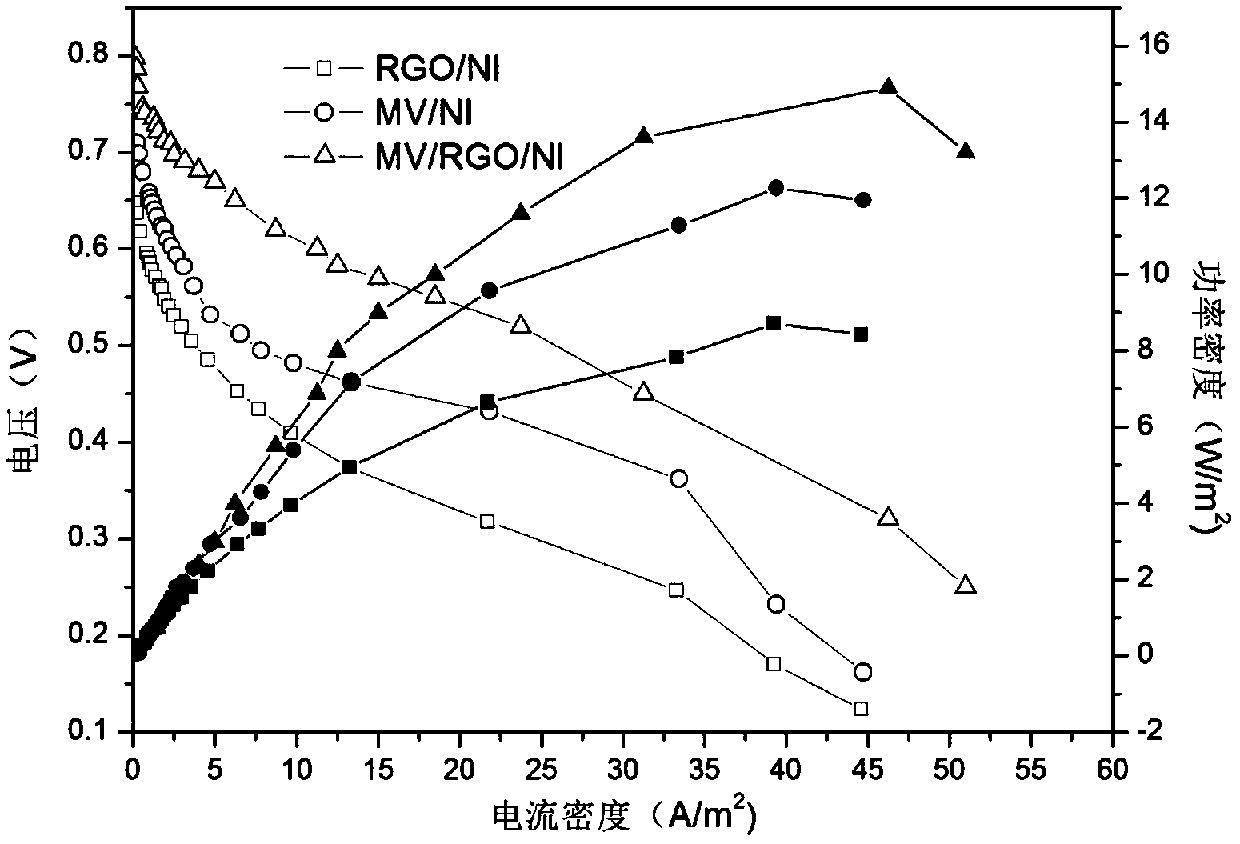

[0044] Comparison of power density curves of biomass alkaline fuel cells corresponding to three different anodes:

[0045] figure 2 Shown are the power density curves of the cells for the three different anodes. Square among the figure represents that battery anode is electrodeposited graphene on the surface of nickel foam (manufacturing steps are the same as (1), (2), (3), (4), (5) steps of Example 1); icon circle represents battery The anode is doped and immobilized methyl viologen on the foamed nickel (the manufacturing step is except that the graphene is not deposited on the foamed nickel, and is (6), (7), (8), (9), (10) of embodiment 1 ) steps are the same); the triangle indicates that the battery anode is the anode obtained by doping and fixing methyl viologen on the graphene-modified nickel foam composite material prepared in Example 1. The hollow icon in the figure indicates the variation trend of voltage, and the corresponding solid icon indicates the variation tre...

Embodiment 3

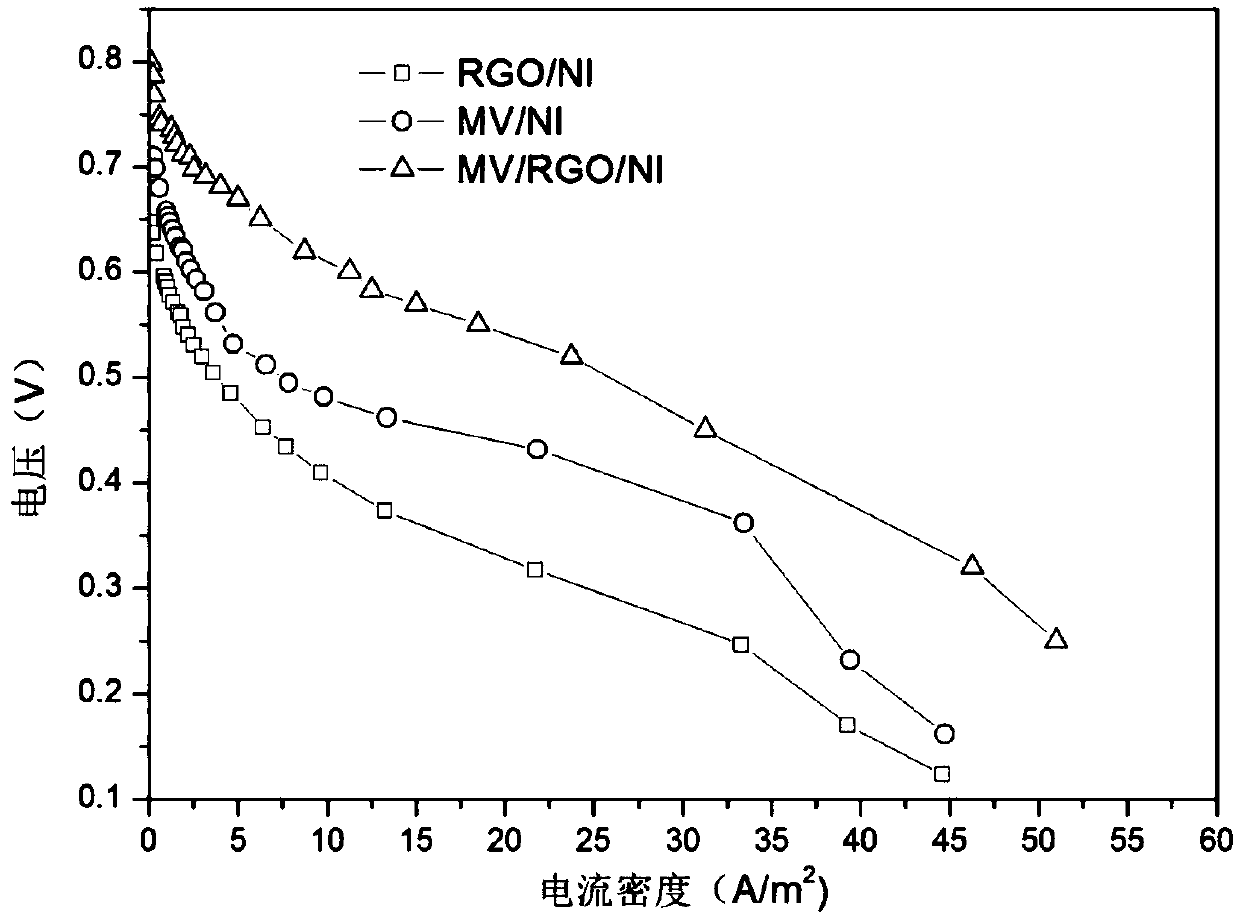

[0047] Embodiment 3: Comparison of polarization curves of biomass alkaline fuel cells corresponding to three different anodes:

[0048] image 3 Shown are the polarization curves of the cells corresponding to three different anodes. In the figure, the block represents that the battery anode is electrodeposited graphene on the surface of nickel foam (the production steps are the same as (1), (2), (3), (4), and (5) steps of Example 1); the icon circle represents the battery anode For doping and immobilization methyl viologen on the foamed nickel (manufacturing steps do not deposit graphene except on the foamed nickel, and be (6), (7), (8), (9), (10) steps of example 1 The same); the triangle indicates that the battery anode is the anode obtained by doping and fixing methyl viologen on the graphene-modified nickel foam composite material prepared in Example 1. The battery used is a single-chamber glucose fuel cell, the concentration of glucose in the battery is 1M, and the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com