Peeling antifouling paint of single-component propeller and preparing method thereof

An anti-fouling paint and propeller technology, applied in the field of paint, can solve the problems of difficult anti-fouling requirements of sodium hypochlorite concentration, being in the laboratory research stage, time-consuming, labor-consuming, and docking fees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

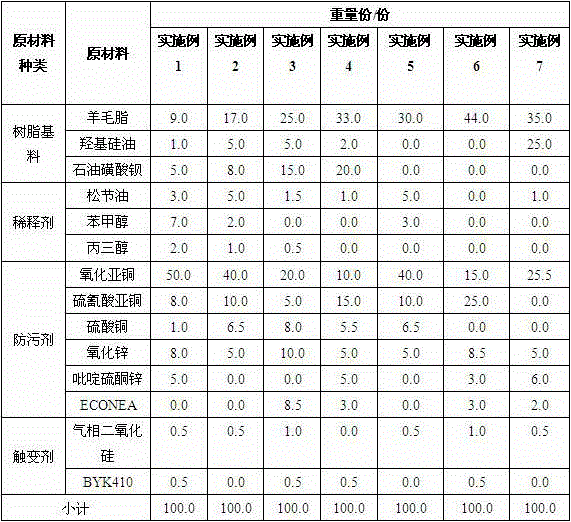

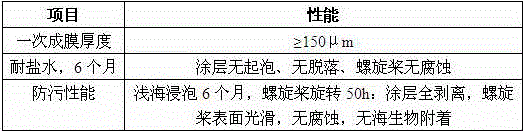

[0015] A single-component propeller peelable antifouling coating, which is composed of the following raw materials in mass percentage: resin base material 15-65%, thinner 0-12%, copper antifouling agent 25-65%, oxidation Zinc 5-15%, organic antifouling agent 0-10%, thixotropic agent 0.5-2%;

[0016] The resin base material is one or more of barium petroleum sulfonate, butter, lanolin, methyl silicone oil, and hydroxyl silicone oil.

[0017] Further, the diluent is one or more of turpentine, benzyl alcohol, and glycerin.

[0018] The copper antifouling agent is one or more of copper powder, cuprous oxide, cuprous thiocyanate, copper sulfate, and copper naphthenate.

[0019] The organic antifouling agent is one or more of zinc pyrithione, copper pyrithione, triphenylboron pyridine, TCPM, chlorothalonil, ECONEA, diuron, and carbendazim.

[0020] The thixotropic agent is fumed silica or BYK410 or a combination of both.

[0021] Enumerate 7 embodiments below, the coating formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com