Preparation method and application of carbon fiber based nickel hydroxide composite material

A composite material, nickel hydroxide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limiting the application of supercapacitor electrodes, the impact of conductivity, and low aggregation, so as to weaken the agglomeration phenomenon , easy to achieve, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

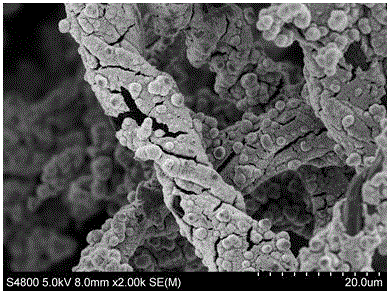

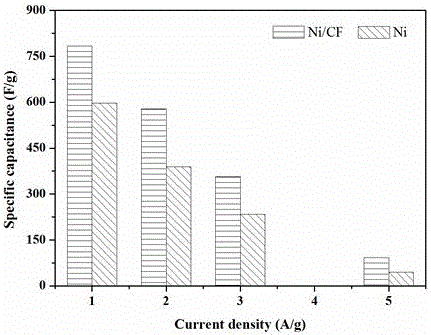

[0019] 2 g of commercially available medical absorbent cotton was placed in a corundum boat and placed in the middle of a tube furnace, heated to 700 °C for 2 h under a nitrogen atmosphere, and the heating rate was 10 °C / min, and then naturally cooled to room temperature under a nitrogen atmosphere , to obtain carbon fiber blocks; add 5.26 g of nickel sulfate, 1.00 g of potassium persulfate and 45 mL of distilled water into a beaker, stir to dissolve, and prepare a mixed solution; wet the carbon fiber blocks with methanol and put them into the mixed solution, and use copper Press the wire to make the carbon fiber block sink into the bottom of the beaker containing the mixed solution, and lean against the inner wall of the beaker, then put a stirring magnetic rotor in the center of the beaker, start stirring, and add 3 mL of ammonia water with a mass fraction of 28% drop by drop. After the addition, stop stirring and let it stand for 1 h, then take out the carbon fiber block sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com