Preparation method for lemon grass essential oil emulsion

A technology of lemongrass essential oil and lemongrass, which is applied in essential oils/fragrances, skin care preparations, chemical instruments and methods, etc., and can solve problems such as poor product status and flavor, low boiling point of volatile components, and inconvenient use , to achieve the effect of promoting degreasing ability, promoting stability, and improving degreasing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

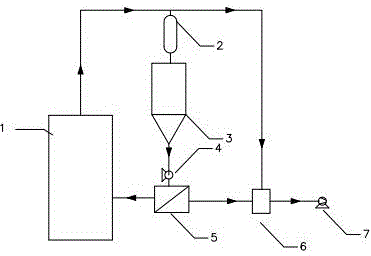

[0020] (1) Preparation of lemongrass crude oil: Grind lemongrass, add 20 times the mass of water, mix well and add to the extraction kettle, and heat the extraction kettle until the liquid temperature in the kettle reaches 55°C, then turn on the vacuum pump to make the extraction kettle Form a vacuum state, the degree of vacuum is subject to the boiling of the body fluid in the extraction kettle, then close the passage between the extraction kettle and the vacuum pump, and make the extraction kettle, condenser, buffer tank, pervaporation system and cold trap form a passage, and start pervaporation Ginkgo biloba essential oil is roughly extracted, and the permeate collected in the cold trap is lemongrass crude oil; the pervaporation uses a PDMS organosilicon composite membrane for separation operation;

[0021] (2) Prepare the water phase: take 2 parts of decaglycerol monooleate, dissolve it in 80 parts of glycerin at 40°C, stir and dissolve evenly, then add 8 parts of deionized...

Embodiment 2

[0024] (1) Preparation of lemongrass crude oil: Grind lemongrass, add 100 times the mass of water, mix well and add to the extraction kettle, and heat the extraction kettle until the liquid temperature in the kettle reaches 65°C, then turn on the vacuum pump to make the extraction kettle Form a vacuum state, the degree of vacuum is subject to the boiling of the body fluid in the extraction kettle, then close the passage between the extraction kettle and the vacuum pump, and make the extraction kettle, condenser, buffer tank, pervaporation system and cold trap form a passage, and start pervaporation Ginkgo biloba essential oil is roughly extracted, and the permeate collected in the cold trap is lemongrass crude oil; the pervaporation uses a PDMS organosilicon composite membrane for separation operation;

[0025] (2) Prepare the water phase: take 4 parts of octaglycerol monostearate, dissolve in 60 parts of sorbitol at 60°C, stir and dissolve evenly, then add 12 parts of deionize...

Embodiment 3

[0028] (1) Preparation of lemongrass crude oil: Grind lemongrass, add 60 times the mass of water, mix well and add to the extraction kettle, and heat the extraction kettle until the liquid temperature in the kettle reaches 60°C, then turn on the vacuum pump to make the extraction kettle Form a vacuum state, the degree of vacuum is subject to the boiling of the body fluid in the extraction kettle, then close the passage between the extraction kettle and the vacuum pump, and make the extraction kettle, condenser, buffer tank, pervaporation system and cold trap form a passage, and start pervaporation Ginkgo biloba essential oil is roughly extracted, and the permeate collected in the cold trap is lemongrass crude oil; the pervaporation uses a PDMS organosilicon composite membrane for separation operation;

[0029] (2) Prepare the water phase: take 3 parts of decaglycerol palmitate, dissolve it in 70 parts of glycerin at 50°C, stir and dissolve evenly, then add 10 parts of deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com