Preparation method of wood-plastic composite material aid

A wood-plastic composite material and additive technology, applied in the field of composite materials, can solve problems such as poor mechanical properties, and achieve the effects of improving crystallinity, wide application fields and improving heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

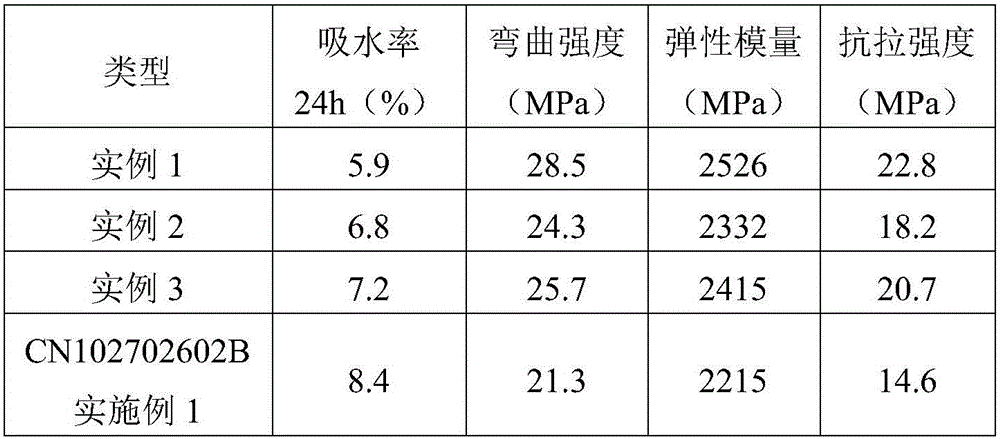

Examples

preparation example Construction

[0019] The present invention provides a method for preparing wood-plastic composite additives. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below.

[0020] A wood-plastic composite additive is an alumina-aluminum nitride composite heat-conducting ceramic composed of alumina heat-conducting ceramics and aluminum nitride heat-conducting ceramics;

[0021] The alumina-aluminum nitride composite heat-conducting ceramic is prepared according to the following steps:

[0022] 1) The original powders of alumina and aluminum nitride with a purity of more than 99.9% are mixed according to a weight ratio of 1:1, added with absolute ethanol, mixed by wet ball milling for 6-8 hours, and pre-dried in an atmosphere at 1100-1150°C after drying. Burn for 6h;

[0023] 2) Add dehydrated ethanol to the powder obtained in step 1), then wet ball mill and mix for 8-10 hours, and ad...

Embodiment 1

[0027] A wood-plastic composite additive is an alumina-aluminum nitride composite heat-conducting ceramic composed of alumina heat-conducting ceramics and aluminum nitride heat-conducting ceramics;

[0028] The alumina-aluminum nitride composite heat-conducting ceramic is prepared according to the following steps:

[0029] 1) The original powders of alumina and aluminum nitride with a purity of more than 99.9% are mixed according to a weight ratio of 1:1, added with absolute ethanol, mixed by wet ball milling for 7 hours, dried and pre-fired in an atmospheric atmosphere at 1125°C for 6 hours;

[0030] 2) Add dehydrated ethanol to the powder prepared in step 1), then wet ball mill and mix for 9 hours, and add 4% BaCu(B 2 o 5 ), 2% La 2 o 3 and 2% Y 2 o 3 well mixed;

[0031] 3) In the powder obtained in step 2), add 3% polyvinyl alcohol solution and 3% carbon powder in an amount accounting for the total mass of the powder, and after granulation, press molding again, where...

Embodiment 2

[0034] A wood-plastic composite additive is an alumina-aluminum nitride composite heat-conducting ceramic composed of alumina heat-conducting ceramics and aluminum nitride heat-conducting ceramics;

[0035] The alumina-aluminum nitride composite heat-conducting ceramic is prepared according to the following steps:

[0036] 1) The original powders of alumina and aluminum nitride with a purity of more than 99.9% are mixed according to a weight ratio of 1:1, added with absolute ethanol, mixed by wet ball milling for 6 hours, and pre-fired in an atmosphere at 1100 ° C for 6 hours after drying;

[0037] 2) Add dehydrated ethanol to the powder obtained in step 1), then wet ball mill and mix for 8 hours, and add 2% BaCu(B 2 o 5 ), 1% La 2 o 3 and 1% of Y 2 o 3 well mixed;

[0038] 3) In the powder obtained in step 2), add 3% polyvinyl alcohol solution and 3% carbon powder in an amount accounting for the total mass of the powder, and after granulation, press molding again, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com