Morphology-adjustable molybdenum disulfide preparation method

A technology of molybdenum disulfide and morphology, applied in the direction of molybdenum sulfide, etc., can solve problems such as poor conductivity and performance gap, and achieve stable product quality, simple and easy-to-implement product process, and good size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

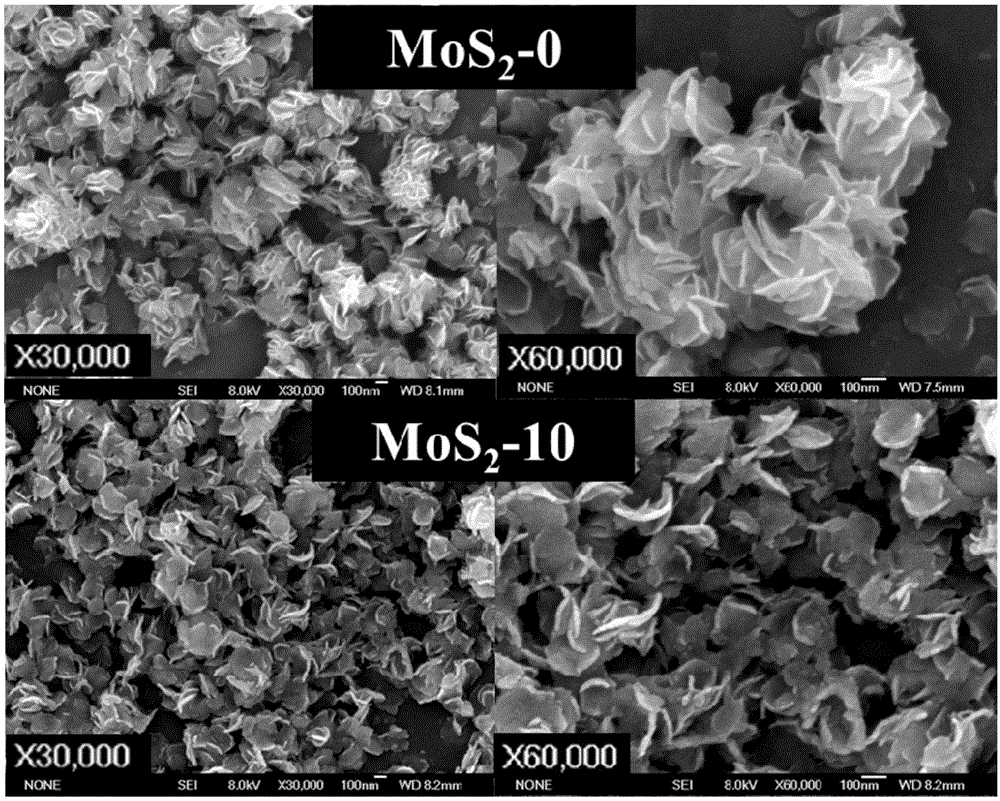

[0011] Accurately weigh 1.2358g of ammonium molybdate and 2.2836g of thiourea into a beaker, add them to 70mL of deionized water, and fully stir on a magnetic stirrer until the medicines are completely dissolved to obtain a uniform, stable and transparent solution. The obtained solution was poured into a polytetrafluoroethylene reactor liner with a volume of 100 mL, placed in a stainless steel autoclave, the reaction temperature was controlled at 200 ° C, the reaction time was 24 h, and cooled to room temperature in air, and samples were collected. Molybdenum disulfide is obtained after centrifugation, washing and drying. looks like figure 1 MoS in 2 -0 shown.

Embodiment 2

[0013] Accurately weigh 1.2358g of ammonium molybdate and 2.2836g of thiourea in a beaker, and add them to the mixed solution of absolute ethanol and deionized water, wherein 10mL of absolute ethanol, 60mL of deionized water, and the total volume of the solution is 70mL. Fully stir on the stirrer until the drug is completely dissolved to obtain a uniform, stable and transparent solution. The obtained solution was poured into a polytetrafluoroethylene reactor liner with a volume of 100 mL, placed in a stainless steel autoclave, the reaction temperature was controlled at 200 ° C, the reaction time was 24 h, and cooled to room temperature in air, and samples were collected. Molybdenum disulfide is obtained after centrifugation, washing and drying. looks like figure 1 MoS in 2 -10 shown.

Embodiment 3

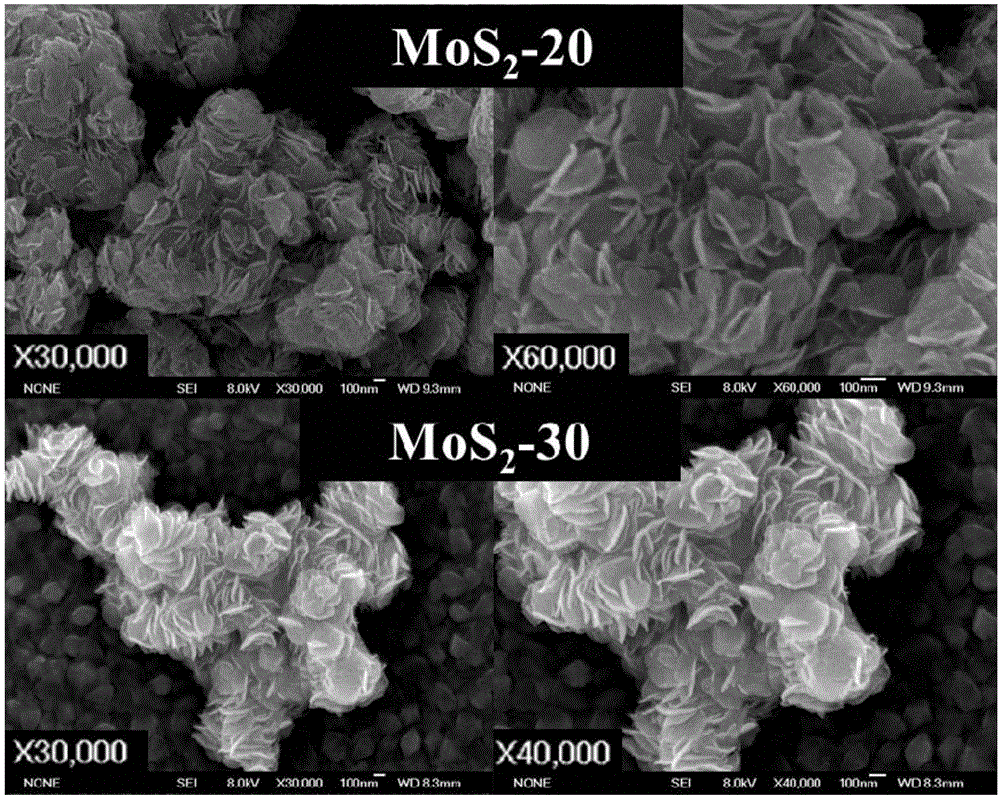

[0015] Accurately weigh 1.2358g of ammonium molybdate and 2.2836g of thiourea in a beaker, and add them to the mixed solution of absolute ethanol and deionized water, wherein 20mL of absolute ethanol, 50mL of deionized water, and the total volume of the solution is 70mL. Fully stir on the stirrer until the drug is completely dissolved to obtain a uniform, stable and transparent solution. The obtained solution was poured into a polytetrafluoroethylene reactor liner with a volume of 100 mL, placed in a stainless steel autoclave, the reaction temperature was controlled at 200 ° C, the reaction time was 24 h, and cooled to room temperature in air, and samples were collected. Molybdenum disulfide is obtained after centrifugation, washing and drying. looks like figure 2 MoS in 2 -20 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com