Canned strong-fragrance round-grained nonglutinous sweet corn and making method thereof

A technology of corn japonica and sweet corn, which is applied in food ingredients as odor modifiers, food science, food preservation and other directions, can solve the problems of incomplete preservation of corn flavor, low production capacity of old equipment and labor time, etc., so as to improve production. The effect of automation technology and product quality, product content uniformity, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of sweet corn japonica can with strong fragrance, said sweet corn japonica can includes: sweet corn grits 15wt% and water 85wt%, the particle diameter of said dry sweet corn grits is 0.2mm, and said sweet corn grits is American sweet corn become.

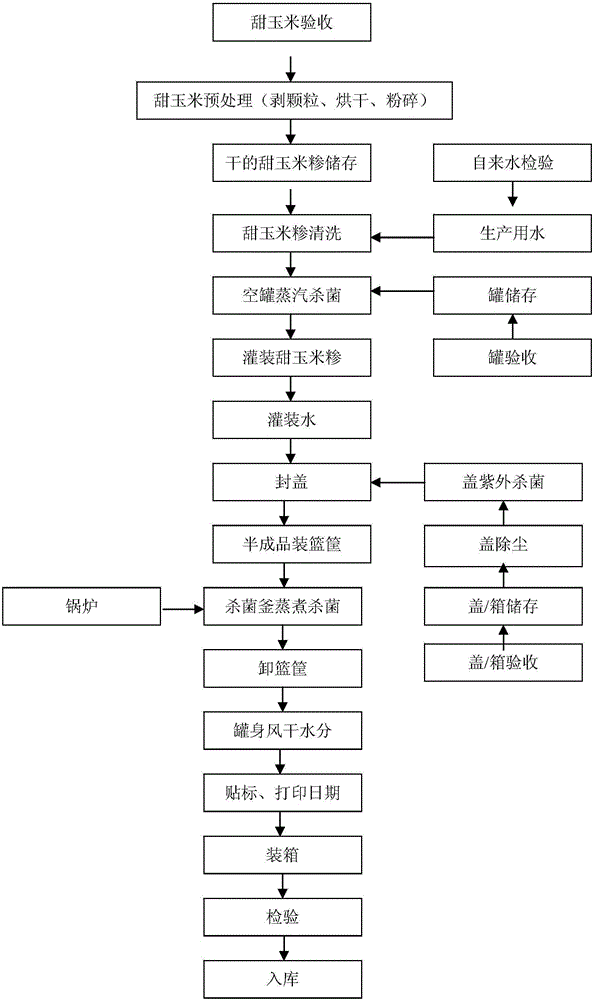

[0038] The above-mentioned process for canned sweet corn japonica, the process specifically includes the following steps:

[0039] Step 1: Production of dry sweet corn grits: After the sweet corn is mature, use equipment to peel off the granules, and pass through a three-stage fluidized bed (first-stage bed temperature: 80±5°C, second-stage bed temperature: 120±5°C, third-stage pass Air inlet into the cold air -5 ℃) drying, cooling, grinding into small particles, to obtain sweet corn grits with a particle size of 0.1-0.2mm;

[0040] Step 2: Pour the dry sweet corn grits into the cleaning tank, wash them with clean water, remove the corn grits skin and impurities, drain the water, and set aside;

[0041] Step 3: Put t...

Embodiment 2

[0052] The invention discloses a canned japonica sweet corn, which comprises 14wt% sweet corn grits and 86wt% water.

[0053] The particle size of the sweet corn grits is 0.1 mm, and the sweet corn grits are made from American sweet corn.

[0054] The above-mentioned process for canned sweet corn japonica, the process specifically includes the following steps:

[0055] Step 1: Production of dry sweet corn grits: After the sweet corn is mature, use equipment to peel off the granules, and pass through a three-stage fluidized bed (first-stage bed temperature: 80±5°C, second-stage bed temperature: 120±5°C, third-stage pass Air inlet into the cold air -5 ℃) drying, cooling, grinding into small particles, to obtain dry sweet corn grits with a particle size of 0.1-0.2mm;

[0056] Step 2: Pour the dry sweet corn grits into the cleaning tank, wash them with clean water, remove the corn grits skin and impurities, drain the water, and set aside;

[0057] Step 3: Put the sweet corn grit...

Embodiment 3

[0068] A canned sweet corn japonica with strong fragrance, said canned sweet corn japonica includes: 13wt% sweet corn grits and 87wt% water, the particle diameter of the sweet corn grits is 0.15mm, and the sweet corn grits is made from American sweet corn.

[0069] The above-mentioned process for canned sweet corn japonica, the process specifically includes the following steps:

[0070] Step 1: Production of dry sweet corn grits: After the sweet corn is mature, use equipment to peel off the granules, and pass through a three-stage fluidized bed (first-stage bed temperature: 80±5°C, second-stage bed temperature: 120±5°C, third-stage pass Air inlet into the cold air -5 ℃) drying, cooling, grinding into small particles, to obtain dry sweet corn grits with a particle size of 0.15mm;

[0071] Step 2: Pour the dry sweet corn grits into the cleaning tank, wash them with clean water, remove the corn grits skin and impurities, drain the water, and set aside;

[0072] Step 3: Put the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com