Method for preparing mesoporous hydroxyapatite through combining microwave and gaseous diffusion

A technology of mesoporous hydroxyapatite and hydroxyapatite, which is applied in the field of materials science, can solve the problems of increasing process complexity and production cost, polluting the purity of mesoporous hydroxyapatite, environmental pollution, etc., and achieves product appearance. Controllable, environmentally friendly and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

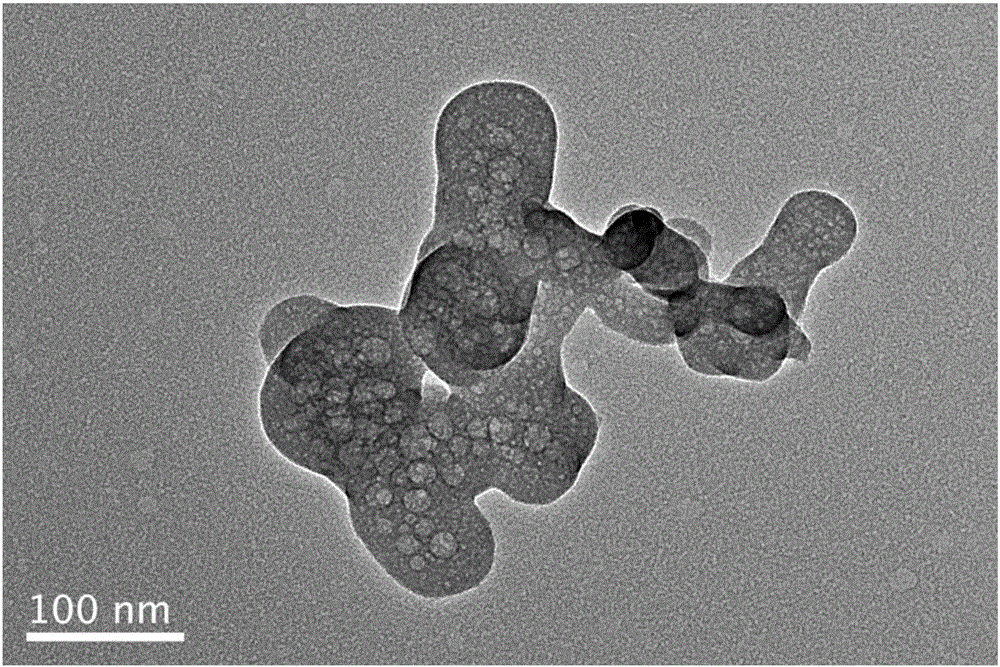

[0029] Using 0.147 g of calcium chloride as the calcium source and 0.142 g of disodium hydrogen phosphate as the phosphorus source, prepare a 200 mL reaction solution with a calcium-to-phosphorus ratio of 1, and use dilute hydrochloric acid to adjust the pH to 4. A cup of 200 mL of concentrated ammonia water diluted five times was placed in the microwave reaction device at the same time as the source of ammonia gas. Use 300W microwave to heat for 5 minutes. After the reaction, the product was collected by filtration, washed with water, and air-dried at 60 °C to obtain a hydroxyapatite with a mesoporous structure ( figure 1 ).

Embodiment 2

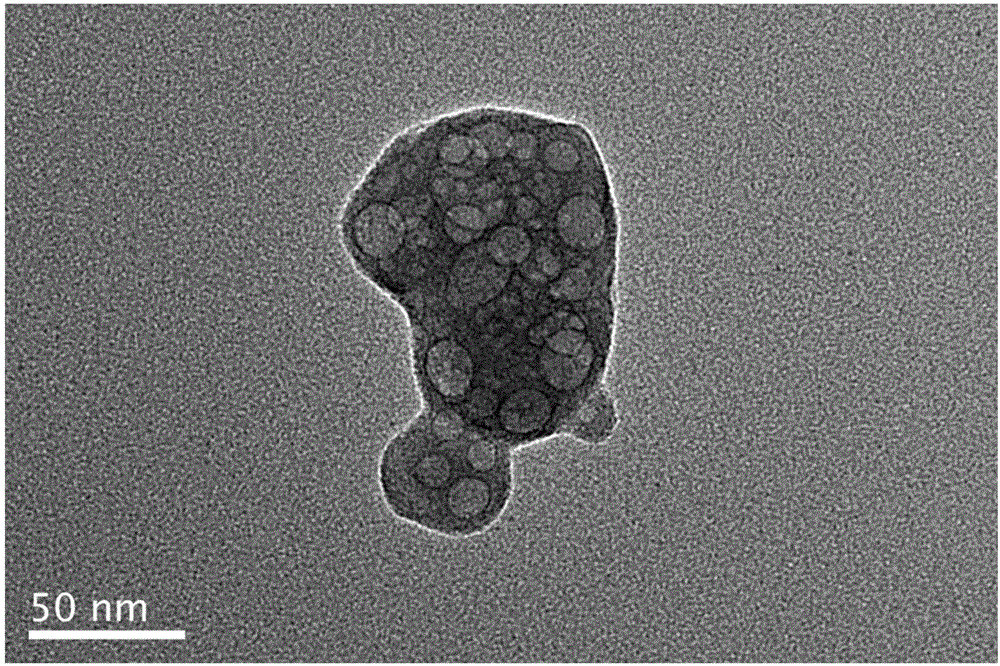

[0031] 0.147 g of calcium chloride was used as the calcium source, and 0.071 g of disodium hydrogen phosphate was used as the phosphorus source to prepare a 200-mL reaction solution with a calcium-to-phosphorus ratio of 2, and dilute hydrochloric acid was used to adjust the pH to 4.5. During the microwave reaction process, ammonia gas is directly introduced into the microwave reaction device. Use 400W microwave to heat for 4 minutes. After the reaction, the product was collected by filtration, washed with water, and air-dried at 80°C to obtain a hydroxyapatite with a mesoporous structure ( figure 2 ).

Embodiment 3

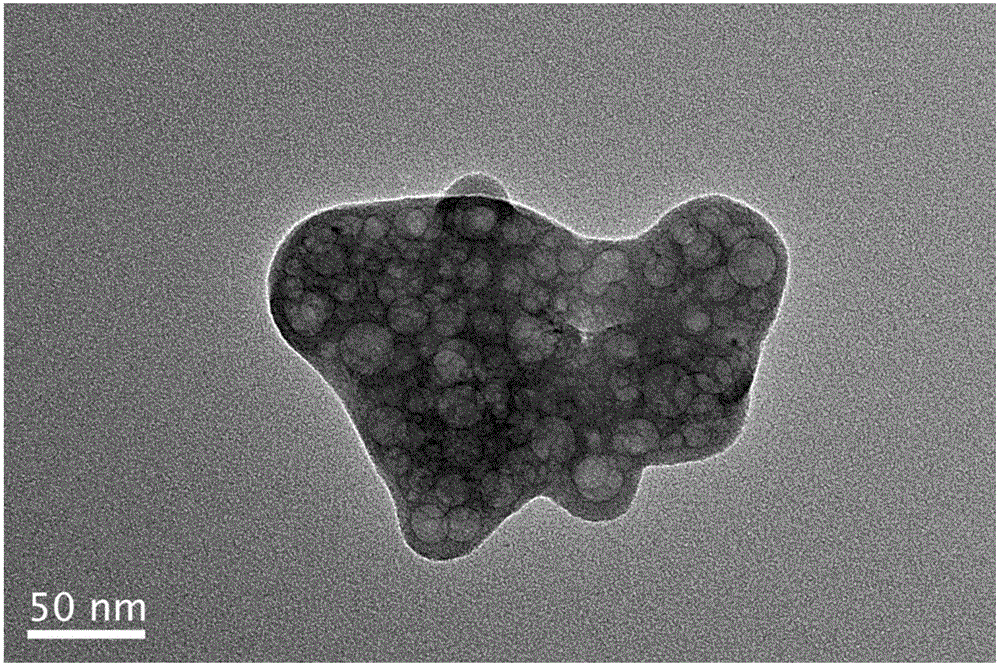

[0033] Using 0.086 g calcium gluconate as the calcium source and 0.016 g sodium dihydrogen phosphate as the phosphorus source, prepare a 100 mL reaction solution with a calcium to phosphorus ratio of 1.5, and use dilute nitric acid to adjust the pH to 4. A cup of 200 mL of concentrated ammonia water diluted ten times was placed in the microwave reaction device at the same time as the source of ammonia gas. Use 300W microwave to heat for 6 minutes, filter and collect the product after the reaction, wash with water, and air-dry at 60 °C to obtain hydroxyapatite with a mesoporous structure ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com