Self-cleaning peelable spray paint with low transparency and preparation method thereof

A transparent and self-cleaning technology, applied in the field of coatings, can solve the problems that do not involve peelable spray paint and reduce the transparency of the paint film, and achieve the effect of preventing water droplets from condensing on the surface of the paint film, low transparency, and protecting personal privacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

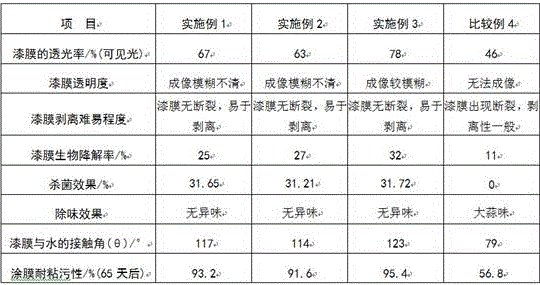

Examples

Embodiment 1

[0040] S1. According to the weight ratio of the formula, add 8 parts of cyclohexane and 2 parts of methylcyclohexane, start stirring, and add 0.5 parts of hydroxymethyl cellulose and 0.5 parts of hydroxymethyl hydroxyethyl cellulose at a speed of 6g / s Vegetables, 1 part of starch, stir well and continue to disperse and activate at 1000r / min for 1 hour to obtain a resin dispersion;

[0041] S2. Add the remaining 26 parts of cyclohexane and 9.8 parts of methylcyclohexane, start stirring, slowly add 16 parts of SEBS elastomer, 24 parts of silicone modified SEBS elastomer, and disperse until completely dissolved; slowly add resin dispersion, 0.8 parts of German INV NFC-810 fluorocarbon modified wetting and leveling agent, 2 parts of fumed silica, 3 parts of diatom mud, 1.5 parts of titanium dioxide, 0.5 parts of pearl powder, dispersed at 1200r / min for 1.5h;

[0042] S3, add 0.3 part of American Li deodorant E1 type, 0.5 part of menthol, 0.6 part of tea polyphenol extract, 1 part ...

Embodiment 2

[0045] S1. According to the formula weight ratio, add 8 parts of cyclohexane, 5 parts of methylcyclohexane, 2 parts of methylcyclopentane, start stirring, and add 0.2 parts of hydroxyethyl methylcellulose at a speed of 5g / s , 0.8 parts of ethyl cellulose, 3 parts of polylactic acid, stir well and continue to disperse and activate at 1000r / min for 1h to obtain a resin dispersion;

[0046]S2. Add the remaining 18 parts of cyclohexane, 10 parts of methylcyclohexane, 5 parts of methylcyclopentane, 1.5 parts of propylene glycol butyl ether, start stirring, and slowly add 25 parts of silicone modified SEBS elastomer, 12 parts of SEBS modified Polypropylene, dispersed until completely dissolved; slowly add resin dispersion, 0.5 parts of German INV NFC-810 fluorocarbon modified wetting and leveling agent, 3 parts of nano glass powder, 4 parts of diatom mud, 0.7 parts of fluorescent powder, to 1200r / min dispersion for 1.5h;

[0047] S3, add 0.1 part of American Li deodorant E1 type, 0...

Embodiment 3

[0050] S1. According to the formula weight ratio, add 15 parts of cyclohexane and 5 parts of methylcyclohexane, start stirring, add 1 part of cellulose acetate propionate and 1 part of cellulose acetate butyrate at a speed of 8g / s , 4 parts of starch, after stirring, continue to disperse and activate at 1000r / min for 0.5h to obtain a resin dispersion;

[0051] S2. Add the remaining 18 parts of cyclohexane, 10 parts of methylcyclohexane, 5 parts of methylcyclopentane, and 2.5 parts of propylene glycol butyl ether, start stirring, and slowly add 22 parts of silicone modified SEBS elastomer and 8 parts of SEBS Modified polyester, dispersed until completely dissolved; slowly add resin dispersion, 0.2 parts of EH-3470 super-wetting leveling agent, 2 parts of fumed silica, 1.5 parts of diatom mud, and disperse at 1200r / min for 1h;

[0052] S3. Add 0.2 part of menthol, 0.5 part of citrus essential oil extract, 0.1 part of hawthorn core extract, 3 parts of nano-silica modified silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com