Self-supporting ultra-thin transparent conductive carbon nanotube film and its preparation method and application

A carbon nanotube film and carbon nanotube technology, applied in the field of material science, can solve the problems of complex post-deposition process and difficulty in self-supporting, and achieve the effects of low environmental factors, good strength, and reduced surface pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

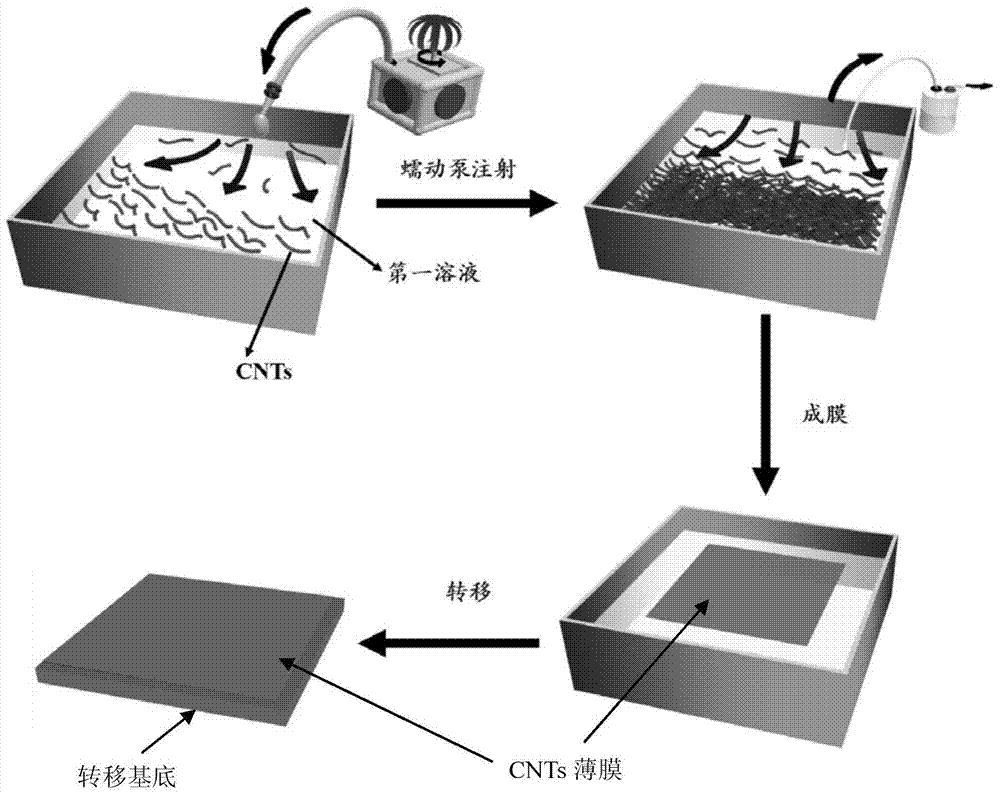

[0044] Further, the preparation method may include:

[0045] providing one or more CNTs;

[0046] The one or more CNTs are uniformly dispersed in a certain solvent to form a carbon nanotube dispersion (CNTs dispersion).

[0047] Wherein, the CNTs dispersion can be formed by any suitable method known in the art, such as ultrasonic, high-speed stirring and so on.

[0048] In some embodiments, the CNTs dispersion can be formed by ultrasonically dispersing the CNTs, and the ultrasonic dispersion time can be 5h-20h, but not limited thereto.

[0049] In some preferred embodiments, the concentration of the CNTs dispersion is 0.005 mg / mL-0.2 mg / mL.

[0050] Wherein, the one or more kinds of CNTs may be single-wall CNTs, multi-wall CNTs and the like.

[0051] More preferably, the one or more CNTs may be chemically functionalized. The corresponding chemical functionalization methods can be known in the industry, for example, you can refer to "Research on the preparation and catalyti...

Embodiment 1

[0094] 1. Add 0.2g of carboxylated CNTs (see "The effect of carboxylated multi-walled carbon nanotubes on the performance of carbon fiber epoxy resin composites", FRP / Composite Materials, 2010, 1, 136-45. "Carboxylation of carbon nanotubes and its electrochemical performance", 2013, 41(7):149-157) was dissolved in 50mL ethanol / water mixed solvent (v:v=2:1), ultrasonically dispersed for 10h, so that CNTs were evenly dispersed in ethanol solvent , forming a CNTs dispersion;

[0095] 2. Dissolve 2g of dodecyltrimethylammonium bromide in 300mL of ethylene glycol, and disperse ultrasonically for 2 hours to form a dodecyltrimethylammonium bromide solution;

[0096] 3. Dissolve 4g of sodium styrene sulfonate in 300mL of ethanol, and disperse ultrasonically for 2 hours to form a sodium styrene sulfonate solution;

[0097] 4. Add 10mL of ethanol to the watch glass, and then inject 2mL of carboxylated CNTs dispersion to the ethanol interface at a rate of 6mL / min through a peristaltic p...

Embodiment 2

[0106] 1. Dissolve 0.2g of aminated CNTs (refer to CN1927706A, CN101177260A, etc.) in 40mL of ethanol / water mixed solvent (v:v=1:1), and ultrasonically disperse for 8 hours, so that the CNTs are evenly dispersed in the ethanol solvent to form CNTs Dispersions;

[0107] 2. Dissolve 3g of polyquaternium-6 in 300mL of ethylene glycol, and disperse ultrasonically for 2 hours to form polyquaternium-6 solution;

[0108] 3. Take 4g of sodium styrene sulfonate and dissolve it in 200mL of ethanol, and disperse it ultrasonically for 2 hours to form a sodium hexadecylbenzene sulfate solution;

[0109] 4. Add 15mL of ethanol to the watch glass, and then inject 2mL of carboxylated CNTs dispersion to the ethanol interface at a rate of 8mL / min through a peristaltic pump to form a stable and transparent CNTs film;

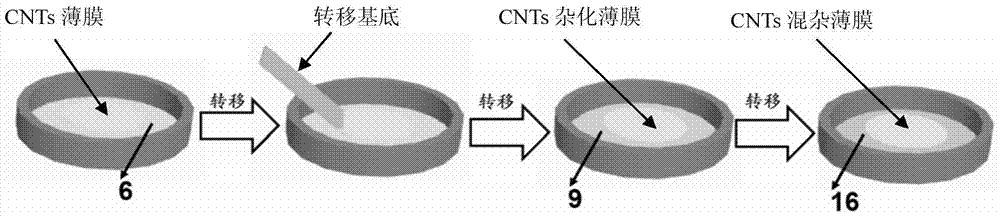

[0110] 5. Heat the polyquaternium-6 solution to 40°C, and transfer the CNTs film to the interface of the polyquaternium-6 solution with a silicon dioxide sheet, and let it stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com