Sour soybean milk and preparation technology thereof

A sour soy milk, the technology of the production method, applied in the field of food processing, to achieve the effect of preventing dental caries, lowering serum cholesterol, and promoting proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

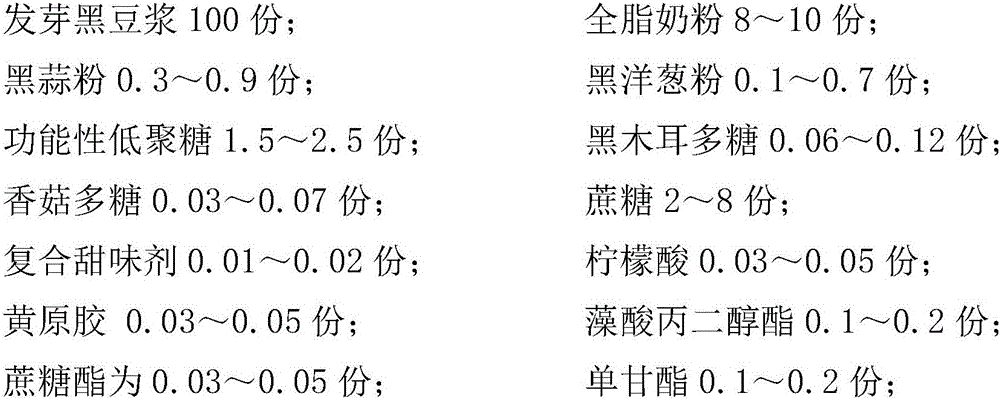

Method used

Image

Examples

Embodiment 1

[0049] Its preparation method comprises the following steps:

[0050] (1) Raw material pretreatment

[0051] A. Preparation of germinated black soybean milk:

[0052] a1) Select black soybeans without pests and mildew, wash them with clear water, and soak them in water at 27°C for 18 hours;

[0053] a2) germinate at 32°C for 50 hours, and take out when the buds are 3mm long;

[0054] a3) adding 3 times the weight of black soybeans themselves, and hot water defibrination at a temperature of 97°C, filtering the slurry through a 110-mesh sieve, removing the bean dregs and retaining the soymilk;

[0055] a4) Heat the soymilk to boiling with constant stirring, and keep it for 12 minutes;

[0056] B. Preparation of black garlic powder and black onion powder: peel off the black garlic and black onion, cut into thin slices, and dry them in a vacuum oven at 52°C and -0.1Mpa for 13 hours. After drying the black garlic and black onions, use a universal Pulverize with a pulverizer, pa...

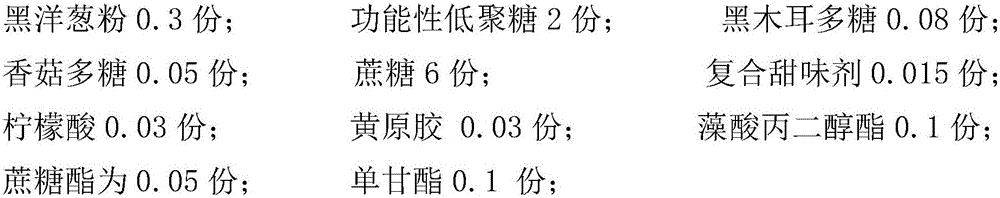

Embodiment 2

[0071] Its preparation method comprises the following steps:

[0072] (1) Raw material pretreatment

[0073] A. Preparation of germinated black soybean milk:

[0074] a1) Select black soybeans without pests and mildew, wash them with clear water, and soak them in water at 25°C for 15 hours;

[0075] a2) germinate at 30°C for 40 hours, and take out when the buds are 2mm long;

[0076] a3) Adding hot water with a weight twice the weight of black soybeans and refining at a temperature of 95°C, filtering the slurry through a 100-mesh sieve, removing bean dregs and retaining soymilk;

[0077] a4) Heat the soymilk to boiling with constant stirring, and keep it for 10 minutes;

[0078] B. Preparation of black garlic powder and black onion powder: peel off the black garlic and black onion, cut into thin slices, and dry them in a vacuum oven at 50°C and -0.1Mpa for 10 hours. After drying the black garlic and black onions, use a universal Pulverize with a pulverizer, pass through a ...

Embodiment 3

[0093] Its preparation method comprises the following steps:

[0094] (1) Raw material pretreatment

[0095] A. Preparation of germinated black soybean milk:

[0096] a1) Select black soybeans without pests and mildew, wash them with clear water, and soak them in water at 30°C for 20 hours;

[0097] a2) germinate at 35°C for 60 hours, and take out when the buds are 4mm long;

[0098] a3) adding 4 times the weight of the black soybeans themselves, and refining with hot water at a temperature of 100°C, filtering the slurry through a 110-mesh sieve to remove the bean dregs and retain the soymilk;

[0099] a4) Heat the soymilk to boiling with constant stirring, and keep it for 15 minutes;

[0100] B. Preparation of black garlic powder and black onion powder: peel off the black garlic and black onion, cut into thin slices, and dry them in a vacuum oven at 55°C and -0.1Mpa for 16 hours. After drying the black garlic and black onions, use a universal Pulverize with a pulverizer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com