High-concentration organic wastewater treatment method and equipment special for same

A technology for organic wastewater treatment and special equipment, which is applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc. System impact and other problems, to achieve good resistance to hardening and passivation, saving pharmaceutical costs, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

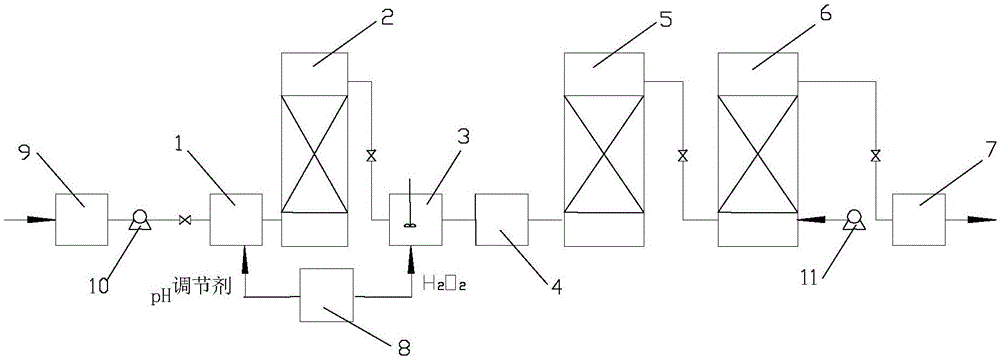

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of Fe / Al / C multi-component micro-electrolytic filler may include the following steps: mixing iron powder, activated carbon, aluminum and bentonite in proportion and adding a certain amount of distilled water to granulate, wherein the ratio of iron powder, activated carbon and aluminum is preferably 3 : 1:1; The regular granules obtained by granulation are placed in a sealed container, and an inert gas such as nitrogen is introduced, and the regular granules are cured under anaerobic conditions for 4 hours; ) under the protection of the regular particle roasting 4h, natural cooling, to obtain Fe / Al / C multi-element micro-electrolytic filler.

[0037] After being treated by the micro-electrolysis reactor 2, the wastewater enters the Fenton reactor 3, and the dosing system 8 adds hydrogen peroxide to the Fenton reactor 3. A large amount of ferrous ions are formed during the multi-element micro-electrolysis reaction process, and enter the Fenton treatme...

Embodiment 1

[0041] The method and the special equipment of the invention are used to treat the effluent of the primary air flotation tank of oil refinery wastewater. Fe / Al / C micro-electrolysis filler is filled in the micro-electrolysis reactor 1, the particle size of the filler is 20 mm, and the mass ratio of Fe, Al, and C in the filler is preferably 3:1:1.

[0042] The COD in the refinery wastewater sample to be treated is 340-430mg / L, and the BOD 5 It is 76~95mg / L. The refinery wastewater enters the micro-electrolysis reactor 2 through the peristaltic pump 10, and is discharged from the secondary sedimentation tank 7 after being treated by the method, and the discharged wastewater water samples are tested.

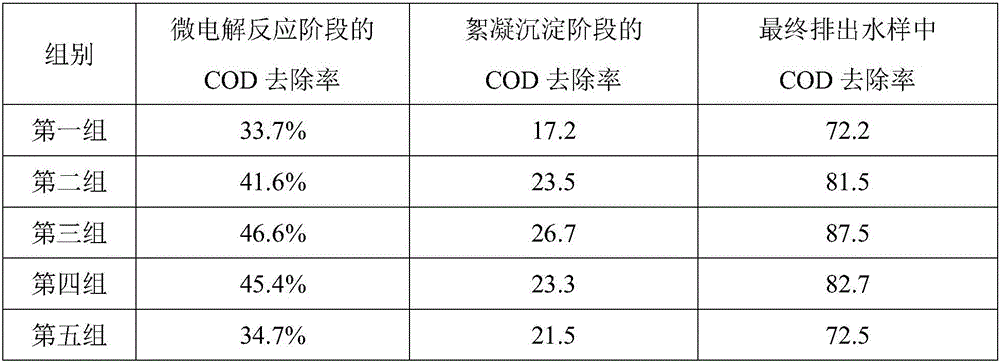

[0043] The experimental conditions are micro-electrolysis section: pH 3, auxiliary electrolyte 0.05mol / L, hydraulic retention time 80min, no aeration; Fenton section: H 2 o 2 The dosing concentration is 1.5ml / L, the pH is 3-4, and the reaction time is 60min; AF-BAF section: anaer...

Embodiment 2

[0046] The pesticide production wastewater is treated by the method and the special equipment of the invention. Fe / Al / C micro-electrolysis filler is filled in the micro-electrolysis reactor 1, the particle size of the filler is 10 mm, and the mass ratio of Fe, Al, and C in the filler is preferably 3:1:1.

[0047] The initial COD value in the pesticide production wastewater sample was 2026-2215mg / L.

[0048] The experimental conditions are micro-electrolysis section: pH 3, auxiliary electrolyte 0.05mol / L, hydraulic retention time 100min, no aeration; Fenton section: H 2 o 2 The dosing concentration is 1.5ml / L, the pH is 3-4, and the reaction time is 80min; AF-BAF section: anaerobic filter column DO is less than 0.5mg / L, aerobic filter column DO2.0-4.0mg / L, hydraulic The residence time is 5+5h.

[0049] After the system has been debugged and operated continuously under this condition for 10 days, the removal rate of COD in the effluent is stable at 92.5%-94.2%, and the averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com