Nafion/orthophosphoric loaded covalent organic framework material composite film, preparation and application

A covalent organic framework and composite membrane technology, which is applied to fuel cell parts, electrical components, circuits, etc., can solve the problems of fuel cells that have not been reported in the literature, and achieve simple and controllable preparation process, good compatibility, The effect of cheap and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

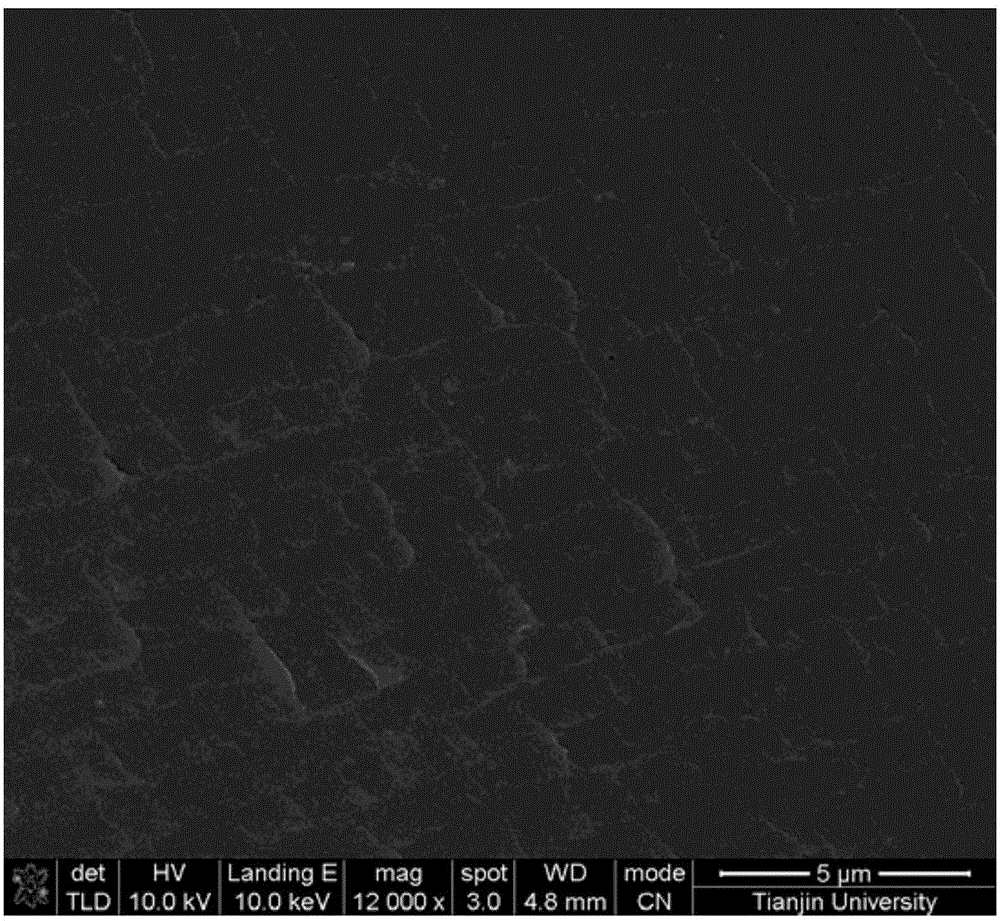

Image

Examples

Embodiment 1

[0023] Embodiment 1: prepare Nafion / H 3 PO 4 @S1-5 Composite film.

[0024] Step 1. Preparation of covalent organic framework material: Dissolve 0.5g melamine and 0.5g terephthalaldehyde in 10mL dimethyl sulfoxide to form a mixture; stir the mixture at 180°C for 72h; cool the mixture to room temperature, pump Filter, wash, and dry to obtain a covalent organic framework material;

[0025] Step 2, phosphoric acid-loaded covalent organic framework material: put 0.5 g of the covalent organic framework material prepared in step 1 into a Soxhlet extractor, and use dichloromethane as a solvent to reflux for 24 hours; place the obtained solid in a Schlenk reaction Vacuumize the tube at 120°C for 18h; when the temperature of the Schlenk reaction tube drops to 80°C, add 10mL of phosphoric acid aqueous solution with a mass percentage of phosphoric acid of 30% to the covalent organic framework material under vacuum and stir for 1h, then return to normal pressure Then continue to stir f...

Embodiment 2

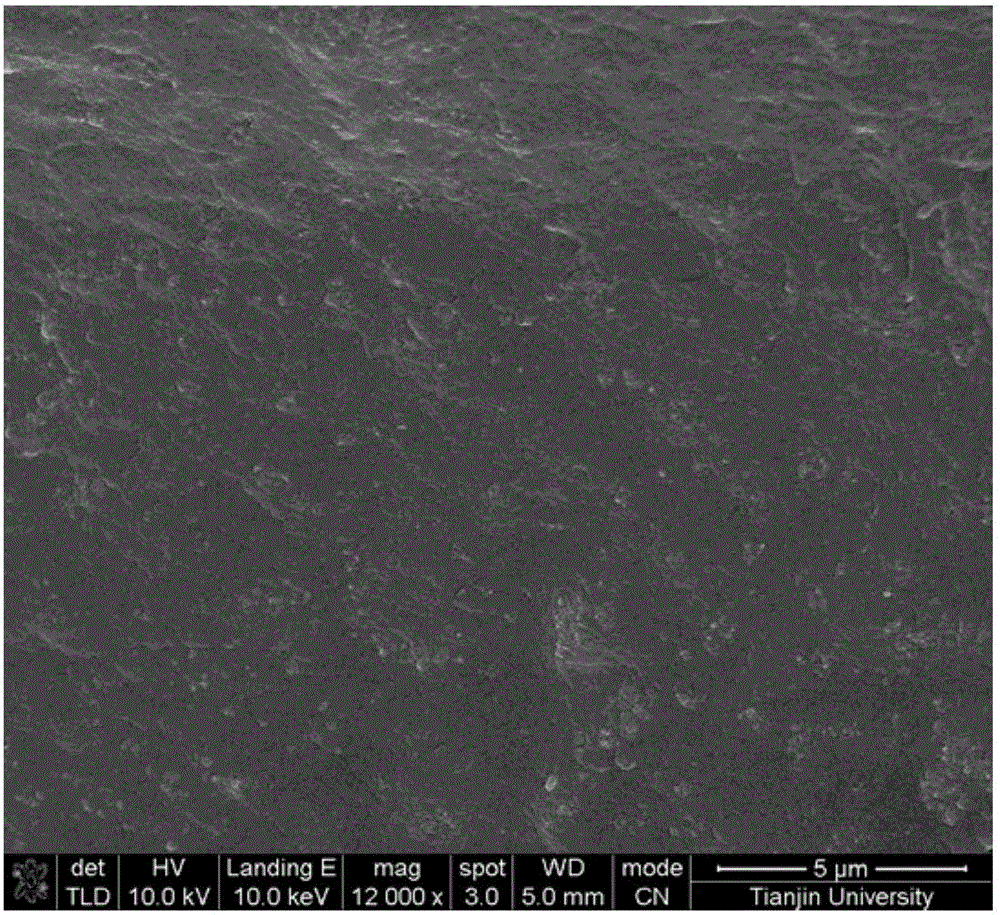

[0028] Embodiment 2: preparation Nafion / H 3 PO 4 @S1-10 Composite film.

[0029] Step 1. Preparation of covalent organic framework material: Dissolve 0.5g of melamine and 1g of terephthalaldehyde in 50mL of dimethyl sulfoxide to form a mixture; stir the mixture at 180°C for 60h; cool the mixture to room temperature, and filter with suction , washed and dried to obtain a covalent organic framework material;

[0030] Step 2, phosphoric acid-loaded covalent organic framework material: put 0.5 g of the covalent organic framework material prepared in step 1 into a Soxhlet extractor, and use dichloromethane as a solvent to reflux for 24 hours; place the obtained solid in a Schlenk reaction Vacuumize the tube at 120°C for 12h; when the temperature of the Schlenk reaction tube drops to 80°C, add 25mL of phosphoric acid aqueous solution with a mass percentage of phosphoric acid of 50% to the covalent organic framework material under vacuum and stir for 3h, and return to normal pressu...

Embodiment 3

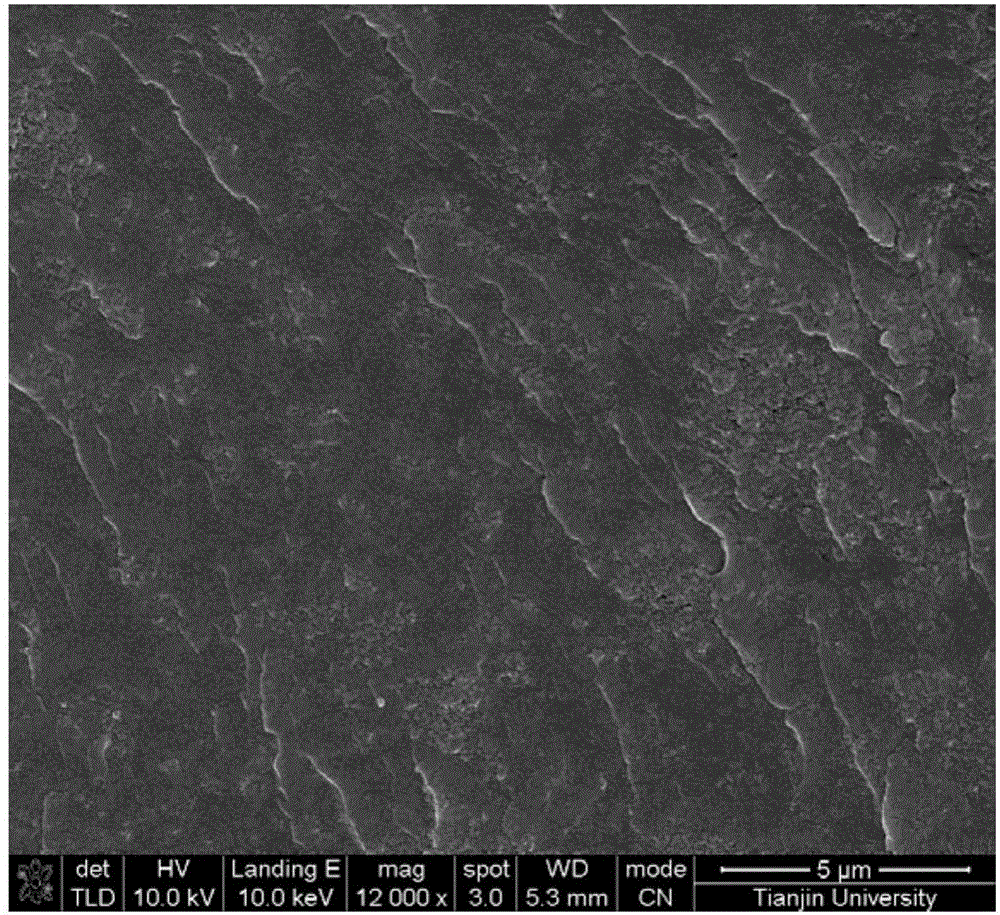

[0033] Embodiment 3: prepare Nafion / H 3 PO 4 @S1-15 Composite film.

[0034] Step 1. Preparation of covalent organic framework material: Dissolve 0.5g melamine and 1.5g terephthalaldehyde in 25mL dimethyl sulfoxide to form a mixture; stir the mixture at 180°C for 48h; cool the mixture to room temperature, pump Filter, wash, and dry to obtain a covalent organic framework material;

[0035] Step 2, phosphoric acid-loaded covalent organic framework material: put 0.5 g of the covalent organic framework material prepared in step 1 into a Soxhlet extractor, and use dichloromethane as a solvent to reflux for 24 hours; place the obtained solid in a Schlenk reaction Vacuumize the tube at 120°C for 24 hours; when the temperature of the Schlenk reaction tube drops to 80°C, add 50 mL of phosphoric acid aqueous solution with a mass percentage of phosphoric acid of 40% to the covalent organic framework material under vacuum and stir for 2 hours, and return to normal pressure Then continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com