Silicon-based nitrogen oxide fluorescent powder as well as preparation method and application thereof

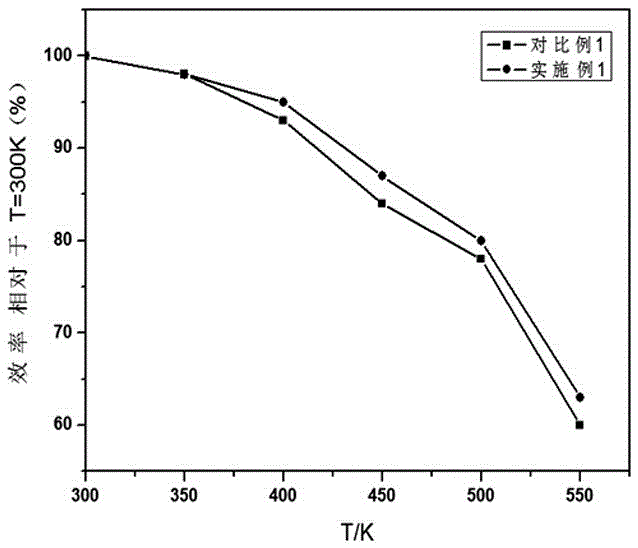

An oxynitride and phosphor technology is applied in the field of silicon-based oxynitride phosphors and their preparation, which can solve the problems of low cost, high quenching temperature and good system stability of green phosphors, and widen the spectral emission range. , The effect of high luminous intensity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

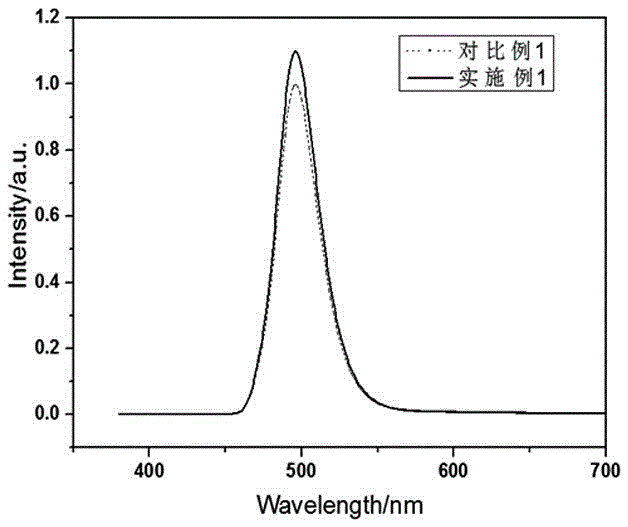

Embodiment 1

[0056] According to Ba 1.95 Mg 0.05 SiO 4 :0.04Eu 2+ ,0.04Y 3+ The stoichiometric ratio of the carbonates or oxides of each element in the flux and the flux is taken by weighing the raw material BaCO 3 430.51g, MgO2.25g, SiO 2 67.21g, Eu 2 o 3 7.87g, Y 2 o 3 5.05g, CaCl 2 6.21g (5% of the molar number of Si), mix well, and after ball milling for 10h, put it in a corundum crucible, open the cover, place the crucible in a tube furnace, and put it in a 3:1 volume ratio of N 2 、H 2 In the mixed gas, the temperature was raised to 1350°C at a rate of 10°C / min, and then kept for 4 hours, then naturally cooled to room temperature, taken out and crushed, passed through a 200-mesh sieve, washed with alcohol, and dried to obtain the precursor Q required for secondary sintering.

[0057] Weigh 400g of the above precursor Q, according to Q (Si 3 N 4 ) 1 Weighing Si in the middle proportion 3 N 4 155.4g, flux SrF 2 5.55g, mixed evenly, after ball milling for 10h, place...

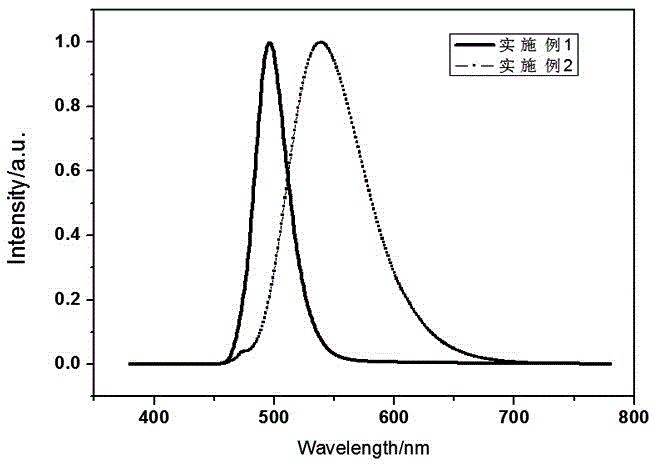

Embodiment 2

[0067] According to Sr 1.95 Mg 0.05 SiO 4 :0.04Eu 2+ ,0.04Y 3+ The stoichiometric ratio of the carbonates or oxides of each element in the flux and the flux is taken by weighing the raw material BaCO 3 411.29g, MgO2.88g, SiO 2 85.84g, Eu 2 o 3 10.06g, Y 2 o 3 6.45g, CaCl 2 7.93g (5% of the molar number of Si), mix well, and after ball milling for 10h, place in a corundum crucible, open the cover, place the crucible in a tube furnace, and place it in a 3:1 volume ratio of N 2 、H 2 In the mixed gas, the temperature was raised to 1350°C at a rate of 10°C / min, and then kept for 4 hours, then naturally cooled to room temperature, taken out and crushed, passed through a 200-mesh sieve, washed with alcohol, and dried to obtain the precursor Q required for secondary sintering.

[0068] Weigh 400g of the above precursor Q, according to Q (Si 3 N 4 ) 1 Weighing Si in the middle proportion 3 N4 220.38g, flux SrF 2 6.2g, mixed evenly, after ball milling for 10h, placed...

Embodiment 3~7

[0074] The proportioning of major ingredients is determined according to each general formula in table 4, and the preparation steps and process conditions are the same as in Example 2, wherein the source of Ge is GeO 2 .

[0075] Table 4:

[0076]

[0077] Compared with Example 2, the incorporation of Ge causes a certain degree of blue shift in the system, and a green phosphor of 530nm to 540nm is obtained. It is normal to decrease the luminous intensity by shifting, but when the Ge doping amount reaches 0.2, the luminous intensity of the system is only half of that of Example 2, which is far lower than the 530nm luminous intensity of the common corresponding silicate. Therefore, the Ge doping amount should not be too high high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com