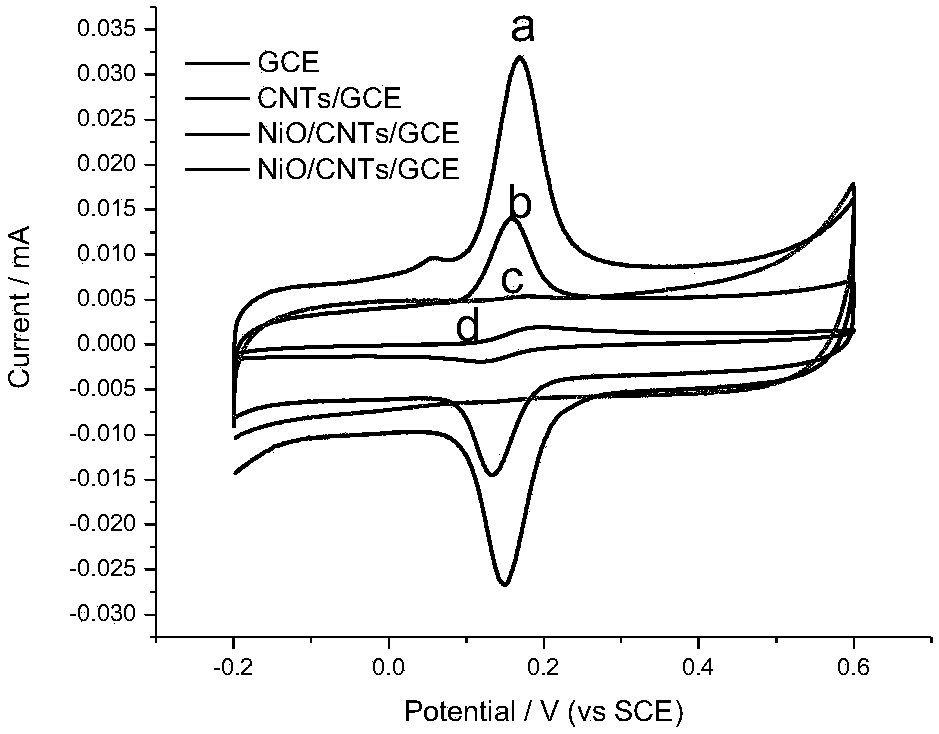

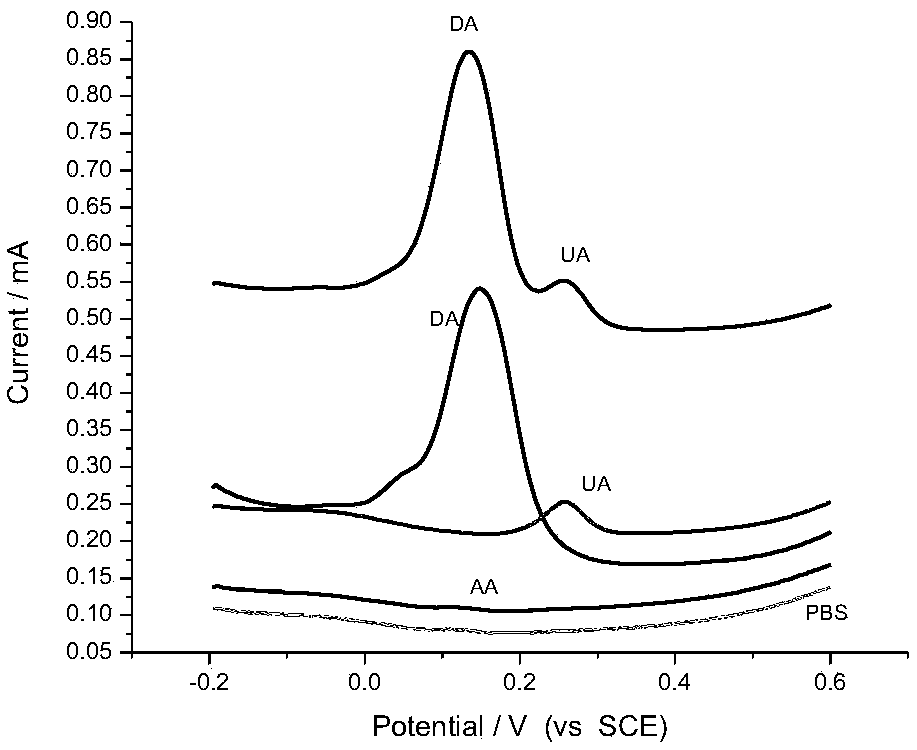

Preparation and application of dopamine sensor based on nickel oxide-carbon nanotubes

A technology of carbon nanotubes and nickel oxide, which is applied in the field of electrochemical detection, can solve the problems of poor reproducibility, achieve strong practicability, simple preparation method, and improve the effect of catalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Firstly, 8 mg of carbon nanotubes were dispersed in 4 mL of absolute ethanol, and then treated by sonication for about 5 minutes. The processed samples were coated on a circular silicon substrate by spin coating, and dried at room temperature. Adjust the reaction temperature of the atomic layer deposition equipment to 140° C., and then put the silicon wafer into the reaction chamber of the atomic layer deposition equipment for heating. The first precursor O 3 Pass it into the reaction chamber of the atomic layer deposition equipment for pulse reaction. The temperature of the reaction chamber is set at 140°C, the pulse reaction is 1s, and the exposure is 10s. In the chamber of the layer deposition equipment, the temperature of the nickelocene precursor raw material bottle is set at 80°C for 1 second of reaction and 10 seconds of exposure. After the reaction is completed, nitrogen is purged for 2 seconds, and then oxygen source O is introduced. 3 , pulse for 1 s, and ...

Embodiment 2

[0062] 1. Firstly, 16 mg of carbon nanotubes were dispersed in 4 mL of absolute ethanol, and then treated by sonication for about 10 minutes. The treated samples were coated on a circular silicon substrate by spin coating, and dried at room temperature. Adjust the reaction temperature of the atomic layer deposition equipment to 180° C., and then put the silicon wafer into the reaction chamber of the atomic layer deposition equipment for heating. The first precursor O 3 Pass it into the reaction chamber of the atomic layer deposition equipment for pulse reaction. The temperature of the reaction chamber is set at 180°C, the pulse reaction is 1s, and the exposure is 6s. After the reaction is completed, nitrogen is purged for 5s, and then the precursor nickelocene is passed into the atom In the chamber of the layer deposition equipment, the temperature of the nickelocene precursor raw material bottle is set at 100°C for 2 seconds of reaction and 8 seconds of exposure. After the re...

Embodiment 3

[0066] 1. Firstly, 24 mg of carbon nanotubes were dispersed in 4 mL of absolute ethanol, and then treated by sonication for about 8 minutes. The treated samples were coated on a circular silicon substrate by spin coating, and dried at room temperature. Adjust the reaction temperature of the atomic layer deposition equipment to 200°C, and then put the silicon wafer into the reaction chamber of the atomic layer deposition equipment for heating. The first precursor O 3 Pass it into the reaction chamber of the atomic layer deposition equipment for pulse reaction. The temperature of the reaction chamber is set at 200°C, the pulse reaction is 2s, and the exposure is 5s. In the chamber of the layer deposition equipment, the temperature of the nickelocene precursor raw material bottle is set at 60°C for 2 seconds, and the exposure is 10 seconds. After the reaction is completed, the nitrogen gas is purged for 8 seconds, and then the oxygen source O is introduced. 3 , pulsed for 2s, ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com