Method for cleanly recycling nickel and/or cobalt from positive electrode material

A cathode material and raw material technology, applied in the field of resource recovery, can solve problems such as inability to achieve high-efficiency recovery, and achieve the effects of less difficulty in removal, strong selectivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

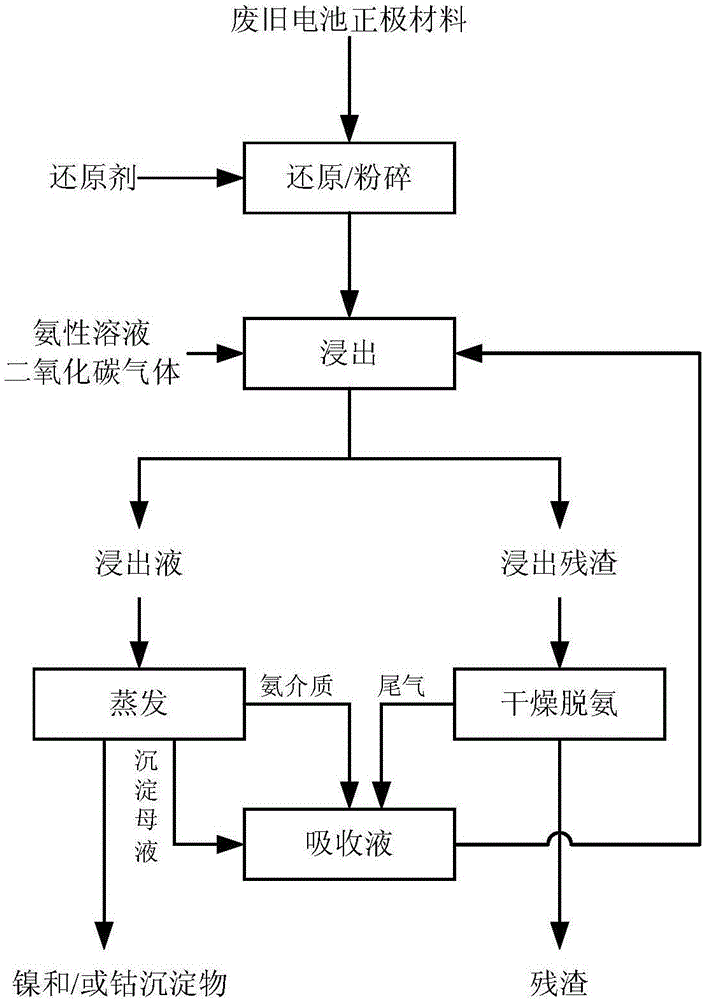

[0053] A method for reclaiming nickel and cobalt in waste nickel-cobalt-manganese ternary cathode materials, said method comprising the steps of:

[0054] (1) Place the waste nickel-cobalt-manganese ternary positive electrode material in a high-temperature furnace and reduce it by coke at 500°C, and grind the reduced block material in a mill to obtain a reduced powder;

[0055] (2) Mix the reduction powder and ammonium bicarbonate solution in the reaction kettle, and the ammonium bicarbonate solution is mixed with NH 3 The concentration of the meter is 50g / L, and the liquid-solid volume mass ratio (L / kg) is 20; After the above operations are completed, the airtight reactor is fed into carbon dioxide gas, and the pressure in the reactor is 0.2MPa, and the reaction temperature is 10°C. The nickel and cobalt in the positive electrode material are leached under the following conditions, and then the liquid-solid separation of the reacted material is carried out to obtain the leach...

Embodiment 2

[0061] A method for reclaiming nickel in the positive electrode material of waste nickel-hydrogen batteries, said method comprising the steps of:

[0062] (1) Put the positive electrode material of the waste nickel-metal hydride battery in a high-temperature furnace and reduce it by carbon monoxide at 700°C, and grind the reduced block material in a mill to obtain a reduced powder;

[0063] (2) Mix the reduction powder and ammonia water in the reaction kettle, and the ammonia water is mixed with NH 3 The concentration of meter is 80g / L, and liquid-solid volume mass ratio (L / kg) is 15; Airtight reactor after finishing above-mentioned operation, feeds carbon dioxide gas, and in reactor pressure is 0.5MPa, and reaction temperature is the condition of 40 ℃ The nickel in the positive electrode material is leached under the following conditions, and the liquid-solid separation of the reacted material is carried out to obtain the leaching residue and the leachate respectively;

[00...

Embodiment 3

[0068] A method for reclaiming nickel in waste nickel-cadmium battery anode materials, said method comprising the steps of:

[0069] (1) Place the waste nickel-cadmium battery anode material in a high-temperature furnace to be reduced by hydrogen at 900°C, and the reduced block is ground in a mill to obtain a reduced powder;

[0070] (2) Mix the reduction powder with the ammonium carbonate solution in the reaction kettle, and the ammonium carbonate solution is mixed with NH 3 The measured concentration is 80g / L, and the liquid-solid volume-to-mass ratio (L / kg) is 15; after the above-mentioned operation is completed, the airtight reactor is fed into carbon dioxide gas, and the reactor pressure is 0.5MPa, and the reaction temperature is 35°C. Realize the leaching of nickel in the positive electrode material under the conditions, separate the liquid and solid of the reacted material, and obtain the leaching residue and leachate respectively;

[0071] (3) Evaporate the leaching s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com