Viscosity reduction-type polycarboxylate water-reducer and preparation method thereof

A viscous polycarboxylate and water-reducing agent technology, applied in the field of construction admixtures, can solve problems such as limited slump retention capacity, inability to achieve low-temperature energy saving, inability to achieve high-strength concrete, etc., to improve construction performance, facilitate production, reduce The effect of high water rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

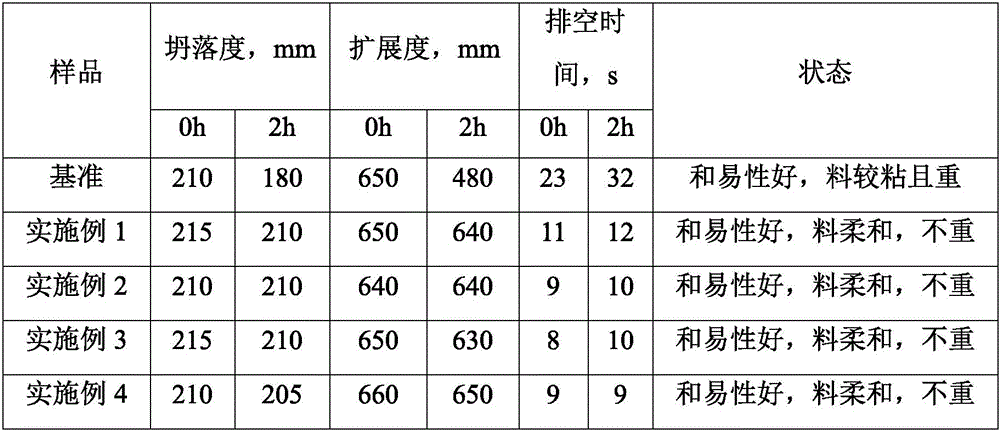

Examples

Embodiment 1

[0025] (1) 100 parts of 3-methyl-3-butene-1-polyoxyethylene ether, 300 parts of maleic anhydride and water are added to the reactor, stirred to dissolve;

[0026] (2) At 30-40°C, add 2 parts of hydrogen peroxide solution at one time to the material obtained in step (1), and stir;

[0027] (3) 0.2 parts of 1,4-cyclohexanedimethanol diacrylate, 0.05 parts of phosphate di(hydroxyethyl acrylate) and 2 parts of thioglycolic acid were added dropwise to the material obtained in step (2). Mix the solution and 1 part of the aqueous solution of ascorbic acid, drop it in 2-4 hours, after the dropwise addition, ripen for 1 hour, and finally, add the aqueous solution of sodium hydroxide (32%) to neutralize it, and obtain the weight average molecular weight of 31000 Viscosity-reducing polycarboxylate superplasticizer (50%).

Embodiment 2

[0029] (1) Add 100 parts of allyl polyoxyethylene ether, 300 parts of itaconic anhydride and water into the reactor, stir to dissolve it;

[0030] (2) At 30-40°C, add 4 parts of ammonium persulfate solution at one time to the material obtained in step (1), and stir;

[0031] (3) 0.3 parts of 1,4-butanediol diacrylate, 0.1 parts of hydrogen phosphate bis(methacryloyloxyethyl) ester and 3 parts of 3 -Mixed solution of mercaptopropionic acid and 1.5 parts of sodium sulfite aqueous solution, dripping over 2 to 4 hours, aging for 1 hour after the addition, and finally, adding sodium hydroxide aqueous solution (32%) to neutralize to obtain the described A viscosity-reducing polycarboxylate superplasticizer (50%) with a weight-average molecular weight of 42,500.

Embodiment 3

[0033] (1) 100 parts of 2-methallyl polyoxyethylene ether, 300 parts of citric anhydride and water are added to the reactor, stirred to dissolve;

[0034] (2) At 30-40°C, add 5 parts of sodium persulfate solution at one time to the material obtained in step (1), and stir;

[0035] (3) Add dropwise a mixture of 0.5 parts of neopentyl glycol diacrylate, 0.15 parts of hydrogen phosphate di(methacryloyloxyethyl) ester and 4 parts of mercaptoethanol in the material obtained in step (2). Solution and the aqueous solution of 2 parts of sodium hypophosphite, dripped in 2~4h, after dropping, aging 1h, finally, add the aqueous solution (32%) of sodium hydroxide, make it neutralize, promptly obtain described weight-average molecular weight of 50300 viscosity-reducing polycarboxylate superplasticizer (50%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com