Phenylboronic-acid-functionalized graphene oxide composite nano material and preparation and application thereof

A graphene composite, nanomaterial technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of low glycoprotein selectivity, low phenylboronic acid monomer affinity, binding Weak ability and other problems, to achieve the effects of environmental friendliness, simple preparation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

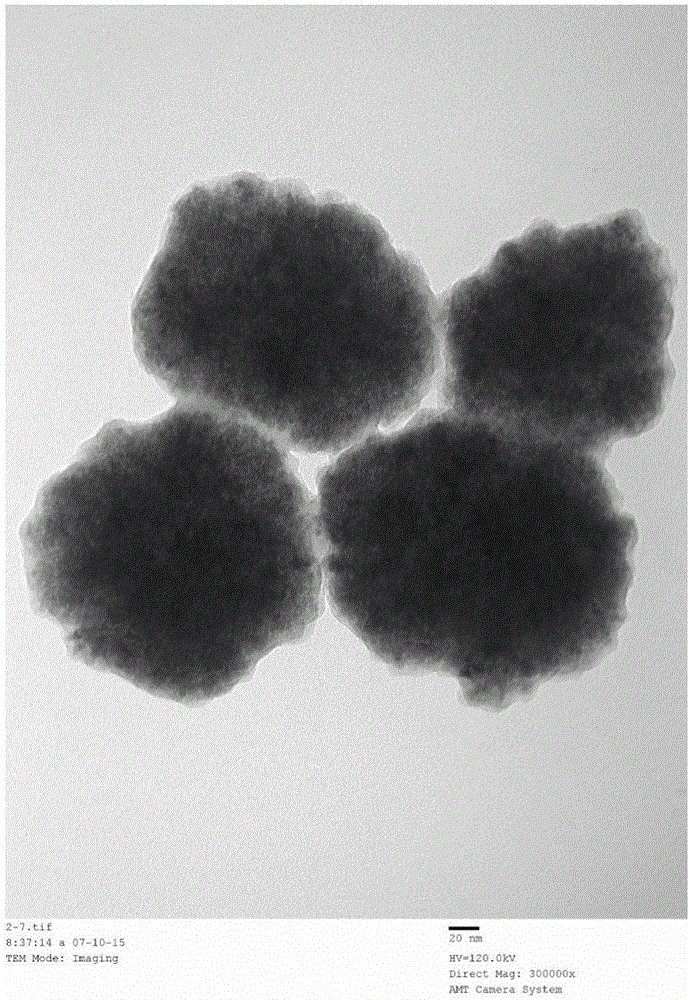

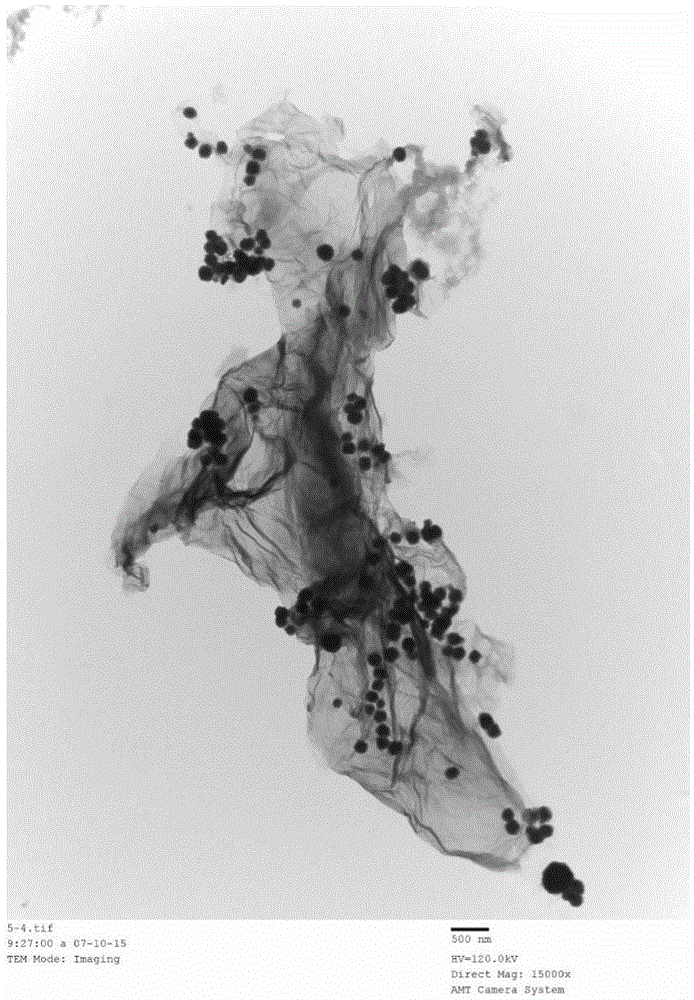

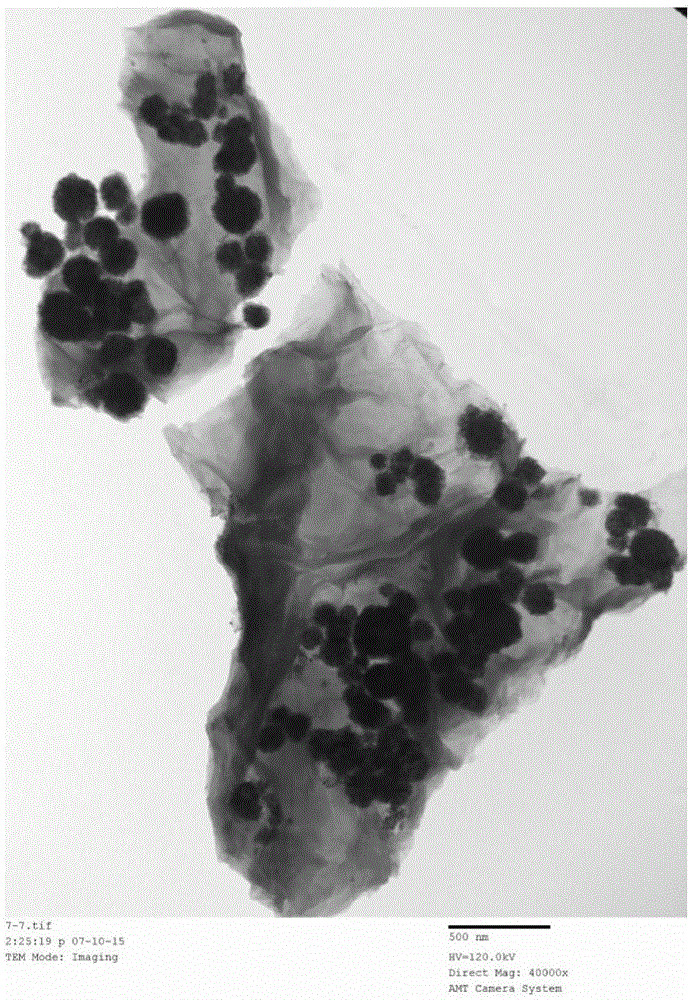

[0028] 1. Fe 3 o 4 Preparation of / PDA / GO / BPEI / CBX: (1) Weigh 1.08g of FeCl 3 ·6H 2 O and 0.2g of trisodium citrate, add 20ml of ethylene glycol, and ultrasonically disperse evenly. Add 1.2 g of anhydrous sodium acetate, and stir magnetically for at least 30 min. Finally, it was transferred to the reactor and reacted at 200°C for 10h. After the reaction was completed, the product was washed three times with deionized water and absolute ethanol, and vacuum-dried to obtain Fe 3 o 4 . (2) Take 100mg of Fe 3 o 4 , add 50ml of 10mM Tris-HCl buffered saline solution with pH=8.5, and disperse evenly by ultrasonic. Quickly add 100 mg of dopamine hydrochloride (DA), and bathe in water at 25°C for 2 hours to obtain Fe 3 o 4 / PDA. After the reaction was completed, the product was washed three times each with deionized water and absolute ethanol, and dried in vacuum. (3) Prepare 1mg / ml GO aqueous solution, and evenly dispersed Fe 3 o 4 / PDA aqueous solution, the mass ratio ...

Embodiment 2

[0031] 1. Fe 3 o 4 Preparation of / PDOPA / GO / PAMAM / CBX: (1) Weigh 1.08g of FeCl 3 ·6H 2O and 0.2g of trisodium citrate, add 20ml of ethylene glycol, and ultrasonically disperse evenly. Add 1.2 g of anhydrous sodium acetate, and stir magnetically for at least 30 min. Finally, it was transferred to the reactor and reacted at 200°C for 10h. After the reaction was completed, the product was washed three times with deionized water and absolute ethanol, and vacuum-dried to obtain Fe 3 o 4 . (2) Take 100mg of Fe 3 o 4 , add 50ml of 10mM Tris-HCl buffered saline solution with pH=8.5, and disperse evenly by ultrasonic. Quickly add 100 mg of 3,4-dihydroxyphenylalanine (DOPA), and bathe in water at 25°C for 2 hours to obtain Fe 3 o 4 / PDOPA. After the reaction was completed, the product was washed three times each with deionized water and absolute ethanol, and dried in vacuum. (3) Prepare 1mg / ml GO aqueous solution, and evenly dispersed Fe 3 o 4 / PDOPA aqueous solution, the...

Embodiment 3

[0035] 1. Fe 3 o 4 Preparation of / PDA / GO / BPEI / CPBA: (1) Weigh 1.08g of FeCl 3 ·6H 2 O and 0.2g of trisodium citrate, add 20ml of ethylene glycol, and ultrasonically disperse evenly. Add 1.2 g of anhydrous sodium acetate, and stir magnetically for at least 30 min. Finally, it was transferred to the reactor and reacted at 200°C for 10h. After the reaction was completed, the product was washed three times with deionized water and absolute ethanol, and vacuum-dried to obtain Fe 3 o 4 . (2) Take 100mg of Fe 3 o 4 , add 50ml of 10mM Tris-HCl buffered saline solution with pH=8.5, and disperse evenly by ultrasonic. Quickly add 100 mg of dopamine hydrochloride and bathe in water at 25°C for 2 hours to obtain Fe 3 o 4 / PDA. After the reaction was completed, the product was washed three times each with deionized water and absolute ethanol, and dried in vacuum. (3) Prepare 1mg / ml GO aqueous solution, and evenly dispersed Fe 3 o 4 / PDA aqueous solution, the mass ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com