A water-based fully synthetic titanium alloy cutting fluid

A titanium alloy and cutting fluid technology, which is applied in the field of water-based fully synthetic titanium alloy cutting fluid, can solve the problems of poor cooling, lubrication and anti-wear effects of cutting fluid, deterioration of tool life, and impact on workpiece surface quality, etc., to avoid sticking Slip phenomenon and adhesive wear, prevent work hardening, and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

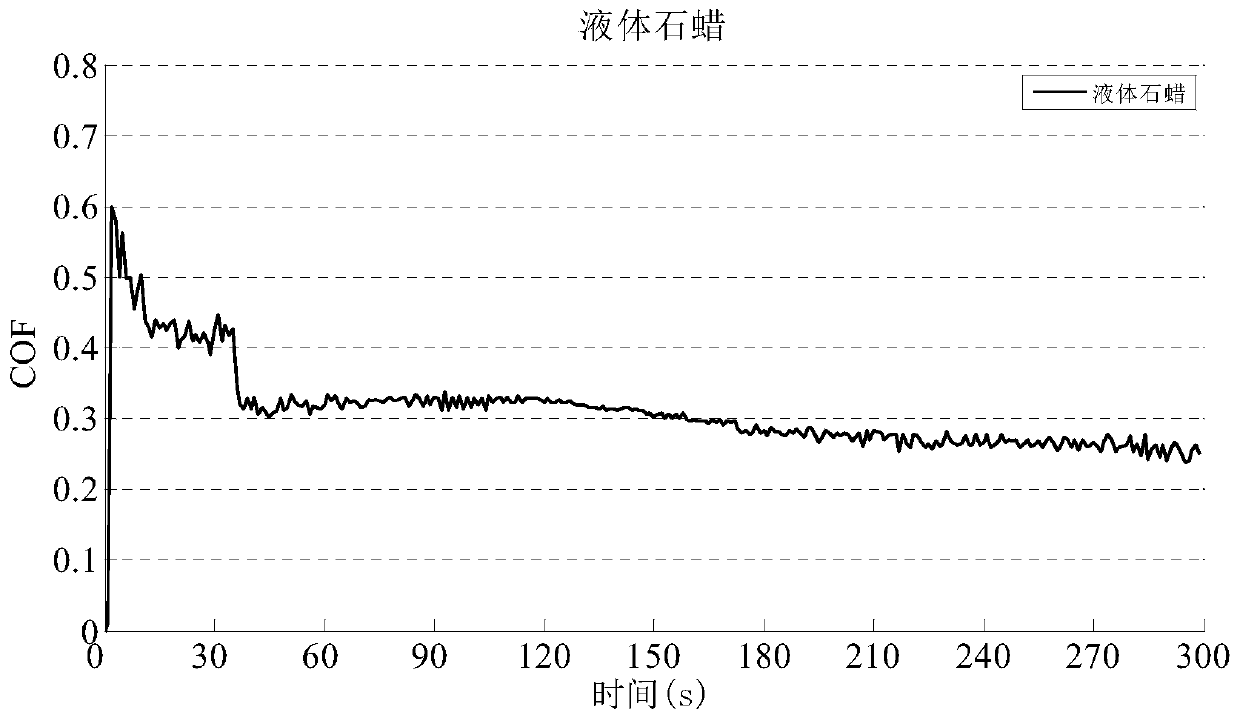

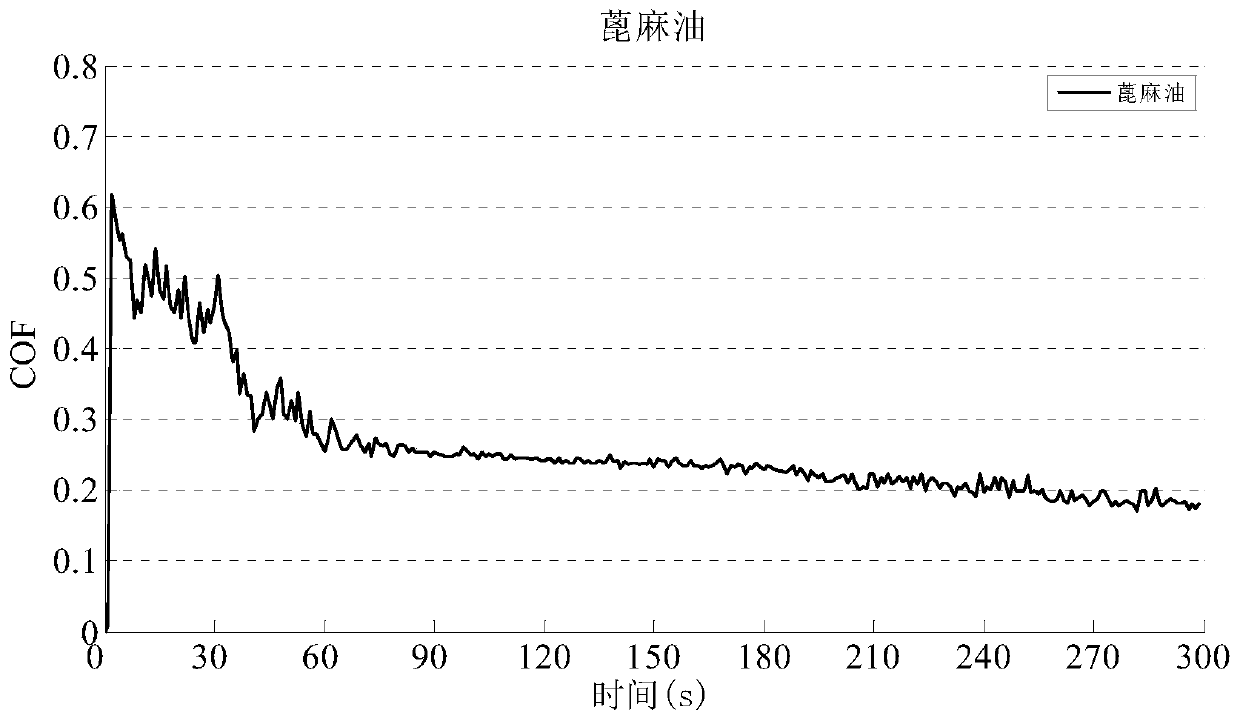

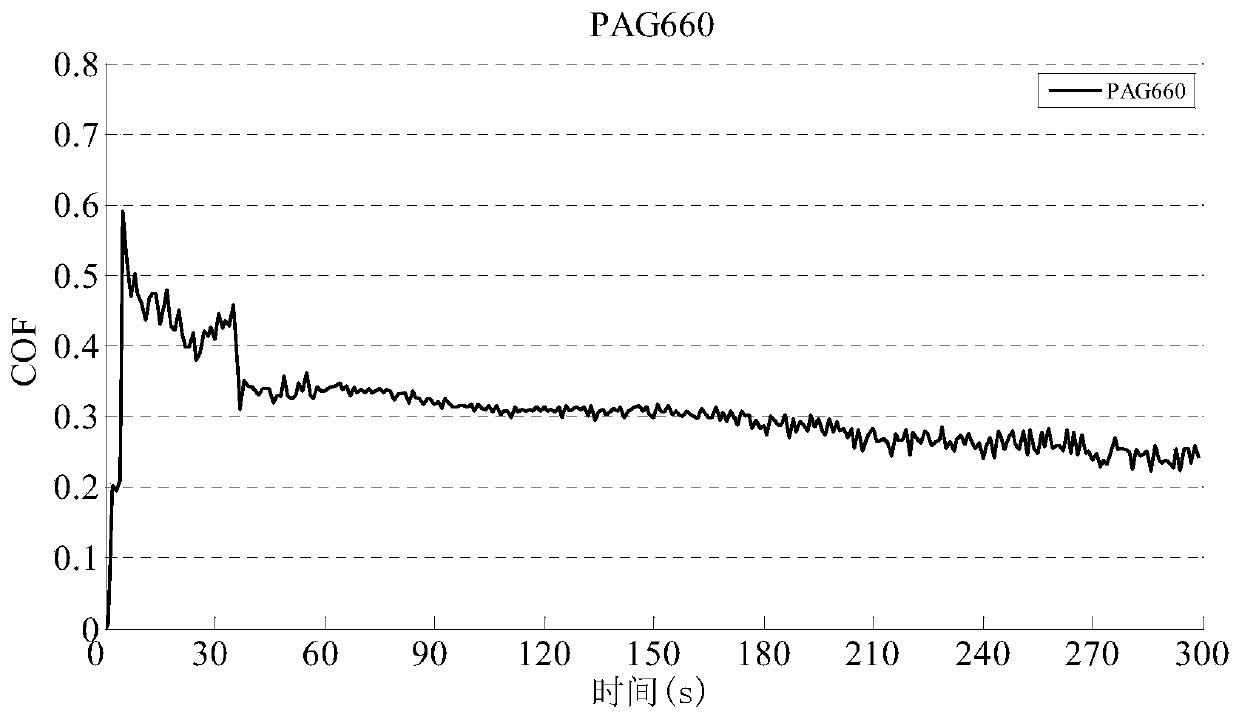

[0045] Embodiment 1 Lubricant Compounding Effect on Lubricating Performance and Comparison with the Lubricating Performance of Other Lubricants

[0046] 1. Grouping and processing methods

[0047] Experimental group 1:

[0048] Take 90g of deionized water, add 1g of alkyl polyethylene glycol ester (Priolube3955, Croda), adjust the pH value to 9.0 with diglycolamine, add deionized water to make up to a total weight of 100g, stir evenly, and use a multifunctional Friction and wear testing machine SRV-4 tests its friction and lubrication performance.

[0049] Experimental group 2:

[0050] Take 90g of deionized water, add 1g of fatty alcohol polyoxyethylene ether phosphate (MOA-3P, Haian Petrochemical), adjust the pH value to 9.0 with diglycolamine, add deionized water to make up to a total weight of 100g, stir evenly, The friction and lubrication performance was tested using a multifunctional friction and wear testing machine SRV-4.

[0051] Experimental group 3:

[0052] T...

Embodiment 2

[0073] Embodiment 2 Comparison of lubricating performance between titanium alloy cutting fluid of the present invention and commercial titanium alloy cutting fluid

[0074] 1. Grouping and processing methods

[0075] Experimental group 1:

[0076] A water-based fully synthetic titanium alloy cutting fluid stock solution for aviation titanium alloy processing, by weight percentage, the water-based cutting fluid consists of the following components: alkyl polyethylene glycol ester (Priolube3955, Croda) 5% , fatty alcohol polyoxyethylene ether phosphate (MOA-3P, Haian Petrochemical) 2.5%, sebacic acid 8%, sodium borate 5%, benzotriazole 0.5%, triethanolamine 20%, potassium hydroxide 0.2%, Organomodified silicone defoamer (Antifoam 793, Degussa) 0.5%, benzisothiazolinone fungicide 1%, and the rest was made up with deionized water. Take an appropriate amount of the stock solution and add deionized water to prepare a 10wt% dilution, stir evenly, and test its friction and lubricati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com