Method and complete device for zero-tendency discharge of reverse osmosis concentrated water of coal chemical industry enterprises

The technology of reverse osmosis concentrated water and reverse osmosis device is applied in the field of reverse osmosis concentrated water treatment system of chemical enterprises to achieve the effect of meeting water inlet requirements, improving efficiency and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

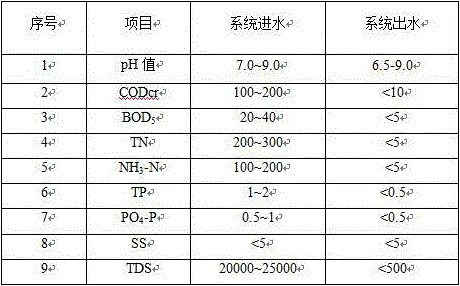

[0050] A method for coal chemical industry reverse osmosis concentrated water to zero discharge is characterized in that it is carried out according to the following steps:

[0051] (1) Concentrated reverse osmosis water enters the regulating tank to homogenize the water quality and quantity;

[0052] (2) The effluent from the reverse osmosis concentrated water adjustment tank enters the catalytic oxidation tank, and the catalytic oxidation tank is filled with MnO 2 -CeO 2 -CoO / AC granular activated carbon catalyst, the filling amount is 1 / 3~3 / 4 of the effective volume of the catalytic oxidation tank; add sulfuric acid to the catalytic oxidation tank to adjust the pH value of concentrated water to 6.5, add 30% (w / w) hydrogen peroxide, and at the same time Access O 3 , O 3 with H 2 o 2 The molar ratio is controlled at 2:1; the residence time of reverse osmosis concentrated water in the catalytic oxidation tank is controlled to 60min;

[0053] The MnO 2 -CeO 2 -CoO / AC ac...

Embodiment 2

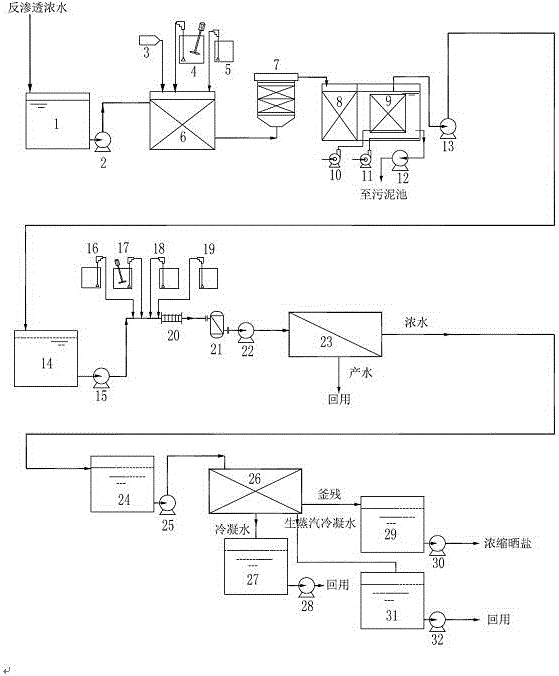

[0064] A complete set of equipment for reverse osmosis concentrated water to zero discharge in coal chemical enterprises, including reverse osmosis concentrated water pretreatment and collection unit, reverse osmosis concentrated water high-pressure membrane reuse treatment and collection unit, reverse osmosis concentrated water evaporation reuse and collection unit.

[0065] The reverse osmosis concentrated water pretreatment and collection unit includes: a reverse osmosis concentrated water regulating tank 1, a concentrated water delivery pump 2, a catalytic oxidation tank 6, an ion exchanger 7, a hydrolytic acidification tank 8, and an MBR tank connected in series through pipelines 9 and MBR produced water pump 13, each reaction tank is equipped with a liquid level gauge to realize the system liquid level high open low stop, the system automatically controls the operation through the program;

[0066] The reverse osmosis concentrated water high-pressure membrane recycling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com