Artificial blood vessel stent with aligned fibers and manufacturing method of artificial blood vessel stent

A technology of artificial blood vessels and fiber orientation, applied in fiber processing, non-woven fabrics, pharmaceutical formulations, etc., to achieve the effect of narrow fiber diameter distribution, simple equipment, and favorable diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the first step, the pure polylactic acid (PLA, (C 6 H 8 O 4 ) n ) Is dissolved in a mixed solvent (the mass ratio of acetone and N,N-dimethylformamide in the mixed solvent w / w=1:1), and is formulated into an 8wt% solution as a spinning solution.

[0030] The second step is to place the spinning solution in a syringe pump equipped with a needle with a diameter of 0.5mm, apply a voltage of 10kV and perform electrospinning at a working distance of 15cm, and receive the fiber through a rotating motor with a stainless steel tube. Adjust the rotation speed of the rotating electric machine to 2000r / min, and obtain the fiber membrane with orientation arrangement.

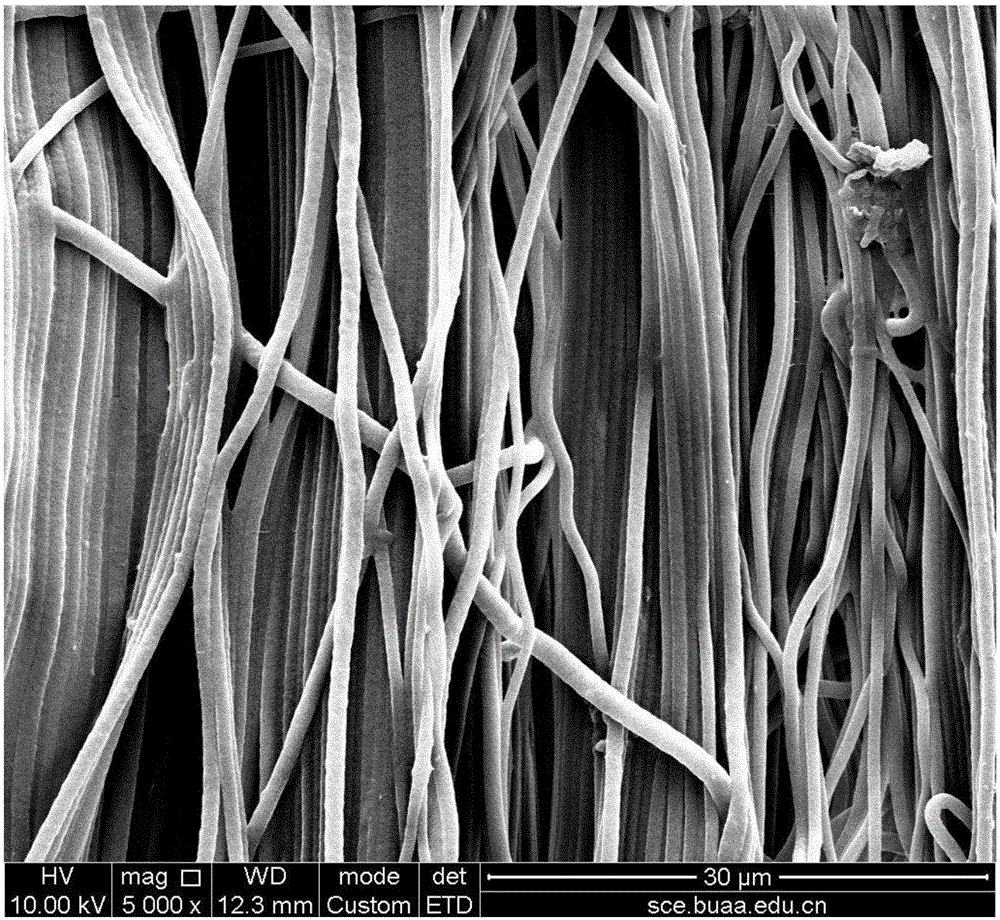

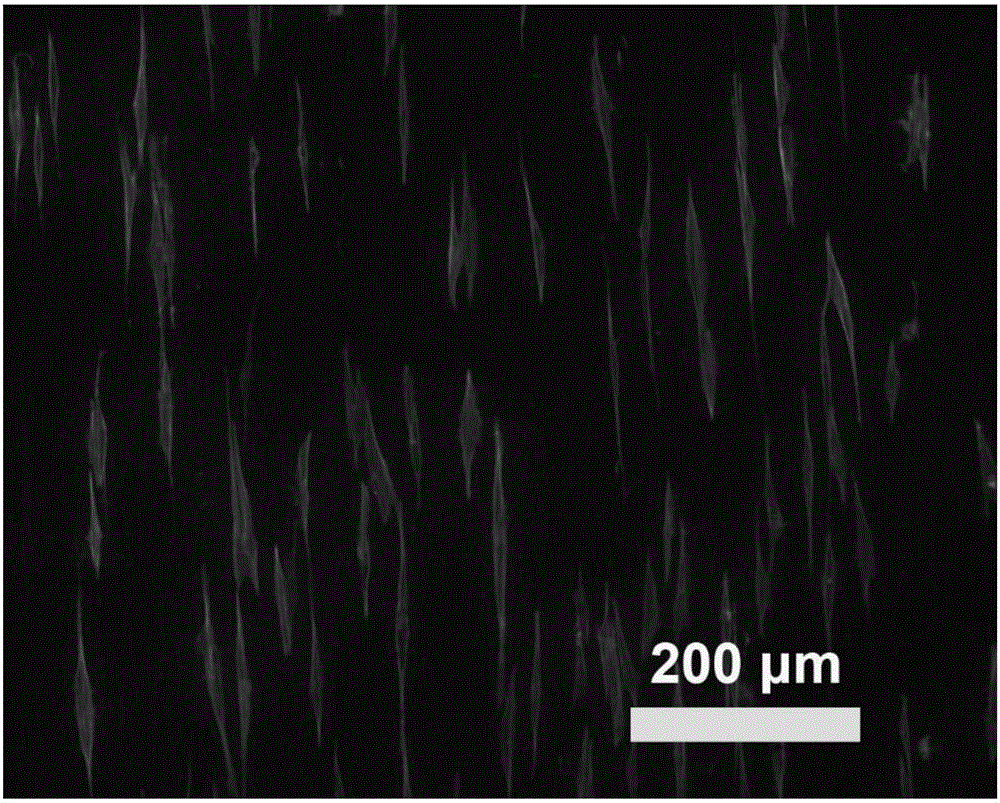

[0031] In the third step, the stainless steel tube with the fiber membrane is soaked in deionized water for 30 minutes to remove the tube, and then dried at 35°C to obtain the target artificial blood vessel stent. Such as figure 1 In the artificial blood vessel stent shown, the artificial blood vessel stent is composed...

Embodiment 2

[0033] Put pure polyurethane (PU, C 28 H 44 N 2 O 11 ), polycaprolactone (PCL, C 6 H 10 O 2 ) The mixture of the two is dissolved in a mixed solvent (the mass ratio of acetone and N,N-dimethylformamide in the mixed solvent w / w=1:1), and a 10wt% solution is prepared as a spinning solution;

[0034] Put the spinning solution in a syringe pump equipped with a needle with a diameter of 0.5~1.0mm, apply a voltage of 15kV and perform electrospinning at a working distance of 10cm, receive nanofibers through a rotating motor with a metal tube, and adjust the rotating motor The oriented fiber can be obtained on the outer circumference of the metal tube. The rotation speed of the rotating electric machine is 2400 r / min.

[0035] Then, the stainless steel tube with oriented fibers was soaked in deionized water for 1 hour to realize the tube removal, and dried at 30°C to obtain an artificial blood vessel stent with oriented fibers. The artificial blood vessel stent is composed of oriented nan...

Embodiment 3

[0037] The pure polycaprolactone (PCL, (C 6 H 10 O 2 ) n ), a mixture of polylactic acid-glycolic acid copolymer (PLGA, 75:25) dissolved in a mixed solvent, the mixed solvent is acetone and N, N-dimethylformamide mass percentage w / w=1 :4, formulated into a spinning solution with a mass percentage of 15wt%.

[0038] The spinning solution is placed in a syringe with an inner diameter of 1mm and fixed on a syringe pump. The oriented composite fiber membrane is obtained by electrospinning. The electrospinning parameters are voltage 25kV, receiving distance 15cm, and motor rotation speed 600r / min, to obtain an oriented and aligned artificial blood vessel fiber membrane.

[0039] Then it is soaked in deionized water for 30 minutes, taken off the tube, and then dried at 30°C to obtain the target artificial blood vessel stent. The fiber arrangement of the target artificial blood vessel stent is an oriented structure, and can guide smooth muscle cells to oriented arrangement, and has good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com