Preparation method of TiO2 quantum dot nano-material and relevant products

A nanomaterial and quantum dot technology, which is applied in the field of preparation of TiO2 quantum dot nanomaterials, can solve the problems of fast reaction rate, large product particle size, and the product purity cannot be well guaranteed, and achieves uniform particles and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

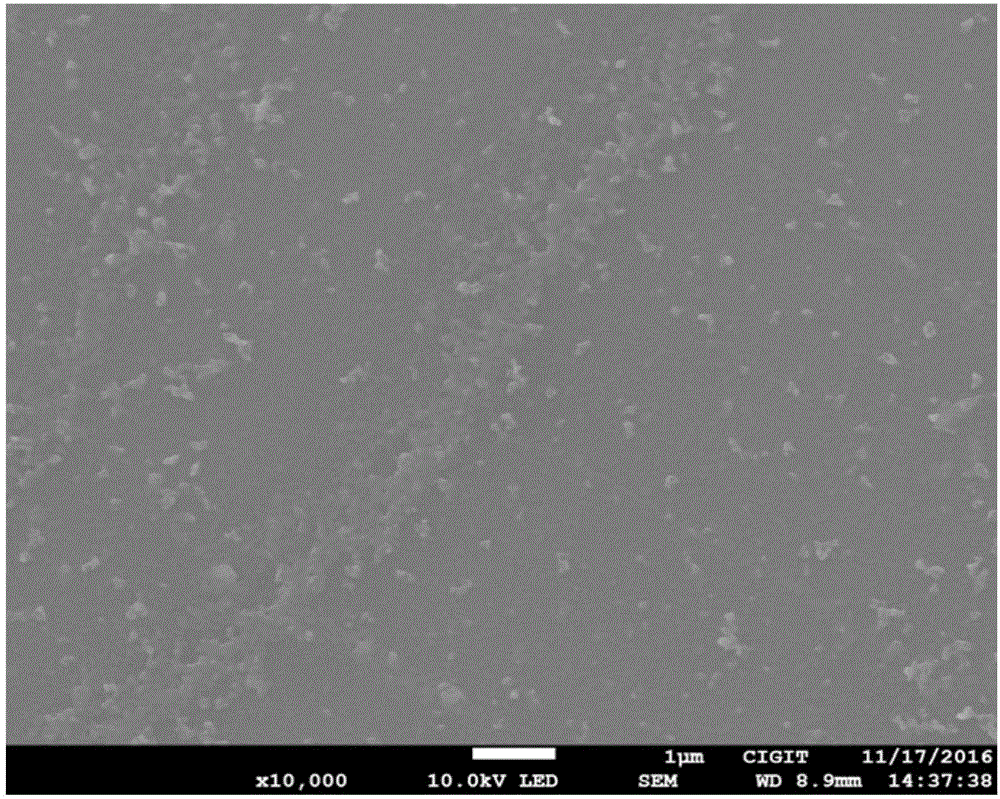

[0027] TiO 2 Preparation of quantum dot nanomaterials:

[0028] 1) Infuse nitrogen gas for one minute to remove the air in the bottle, add 4ml of absolute ethanol, turn on the magnetic stirrer and slowly add 0.5ml of TiCl 4 ;

[0029] 2) Add 15ml of benzyl alcohol to it, put it in an oil bath at 80 degrees Celsius, heat up to 100 degrees Celsius, and keep the temperature constant for 5 hours;

[0030] 3) Add 50 ml of ether to the resulting solution and centrifuge at 8000 rpm for 5 minutes to collect the precipitate;

[0031] 4) Dissolve the precipitate in 20ml ethanol, and vibrate and sonicate to obtain TiO 2 Quantum dot nanomaterials.

Embodiment 2

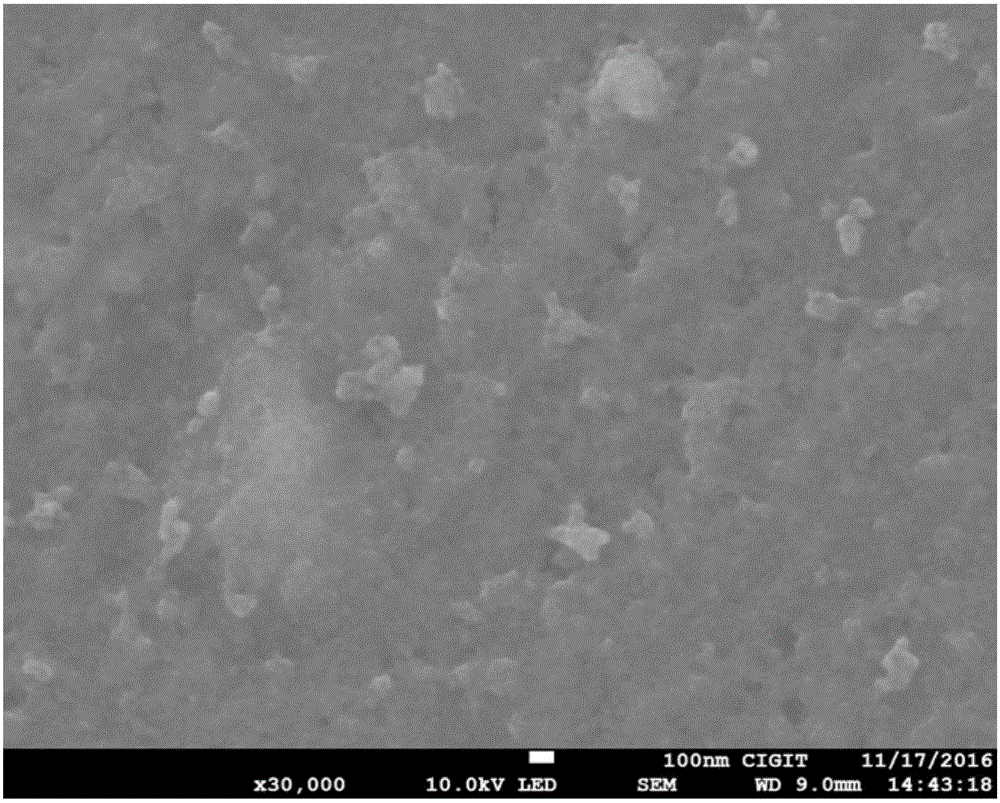

[0033] TiO 2 Preparation of quantum dot nanomaterials:

[0034] 1) Infuse nitrogen gas for one minute to remove the air in the bottle, add 3.4ml of absolute ethanol, turn on the magnetic stirrer and slowly add 0.6ml of TiCl 4 .

[0035] 2) Add 10ml of benzyl alcohol to it, put it in an oil bath at 80 degrees Celsius, heat up to 100 degrees Celsius, and keep the temperature constant for 5 hours.

[0036] 3) Add 50 ml of ether to the resulting solution and centrifuge at 8000 rpm for 5 minutes to collect the precipitate;

[0037] 4) Dissolve the precipitate in 20ml ethanol, and vibrate and sonicate to obtain TiO 2 Quantum dot nanomaterials.

Embodiment 3

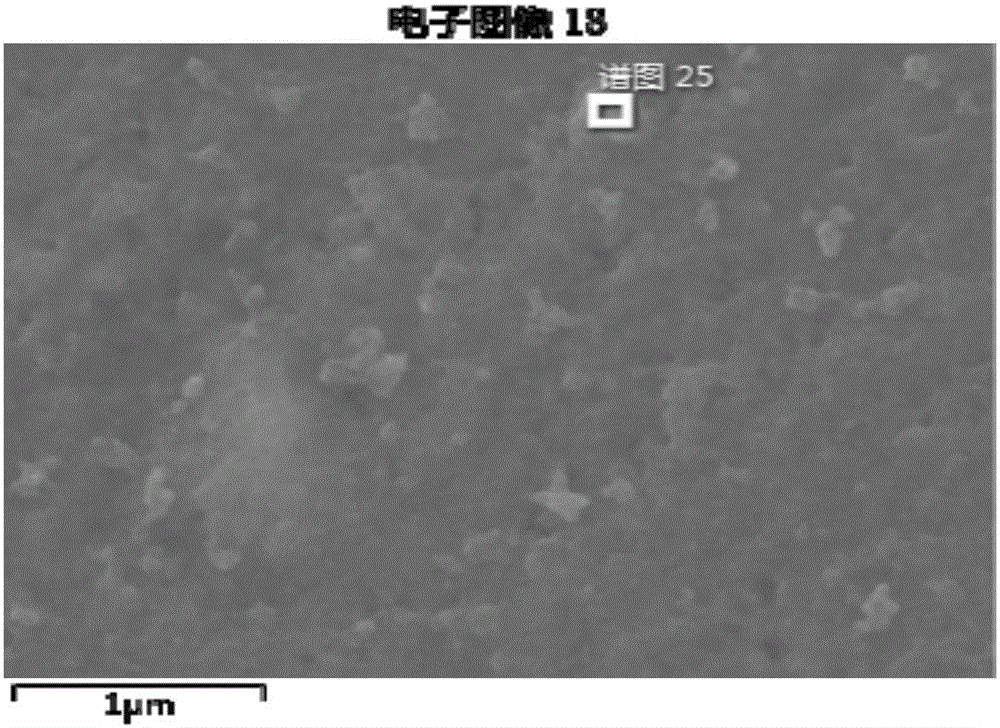

[0039] TiO 2 Preparation of quantum dot nanomaterials:

[0040] 1) Infuse nitrogen gas for one minute to remove the air in the bottle, add 3ml of absolute ethanol, turn on the magnetic stirrer and slowly add 0.5ml of TiCl 4 ;

[0041] 2) Add 10ml of benzyl alcohol to it, put it in an oil bath at 80 degrees Celsius, heat up to 120 degrees Celsius, and keep the temperature constant for 5 hours;

[0042] 3) Add 50 ml of ether to the resulting solution and centrifuge at 8000 rpm for 5 minutes to collect the precipitate;

[0043] 4) Dissolve the precipitate in 20ml ethanol, and vibrate and sonicate to obtain TiO 2 Quantum dot nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com