Method for preparing high-purity dimethyl diallyl ammonium chloride (DMDAAC) monomer

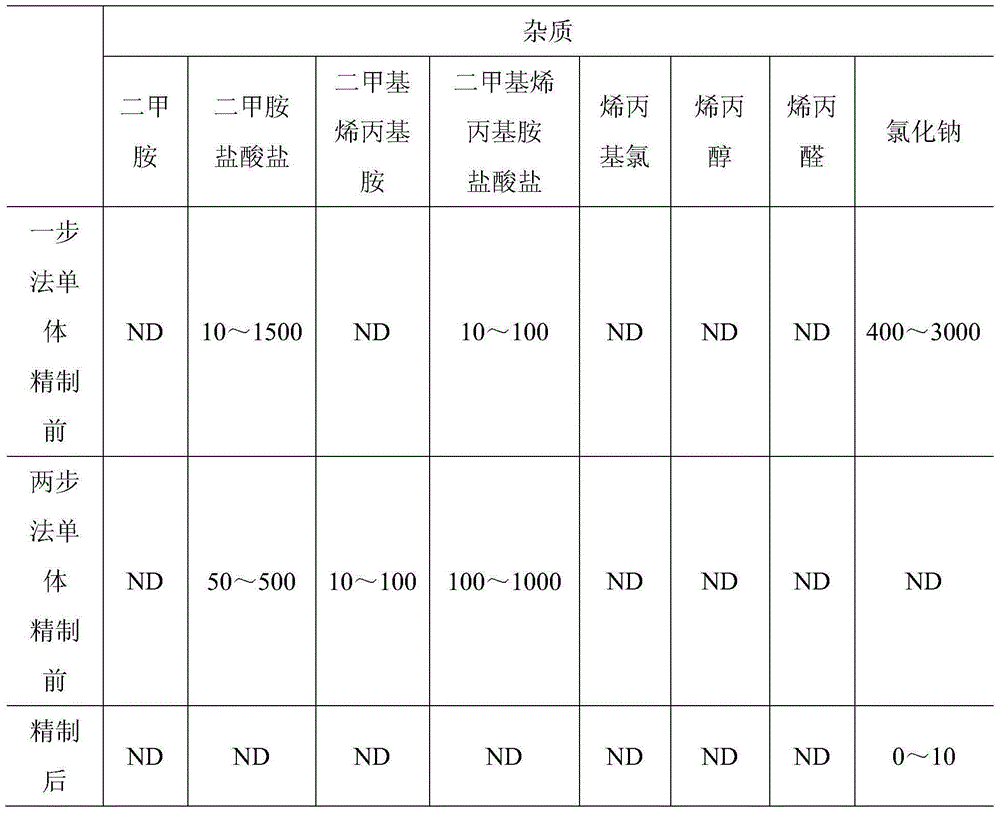

A dimethyl diallyl ammonium chloride, high-purity technology is applied in the field of preparation of cationic quaternary ammonium salt monomers, and can solve the problems of no two-step method to obtain monomer purity, reports, no pure DMDAAC, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

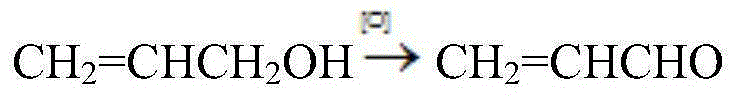

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of high-purity DMDAAC monomer, concrete steps are as follows:

[0055] (1) Adding alkali to release amine: under the condition of stirring at room temperature, in the DMDAAC monomer aqueous solution (40wt%) that is placed in the 40g that is placed in the reactor, one-step process makes dripping the sodium hydroxide aqueous solution that massfraction is 1.0%, adjusts And maintain the pH value at 11.0, and then distill under reduced pressure at 40°C to release the ammonium salt until the pH value of the distillate is constant at 7.0.

[0056] (2) Neutralize residual alkali: add 1% hydrochloric acid aqueous solution to the DMDAAC monomer solution after amine-releasing treatment, adjust the pH value to 7.0, neutralize residual alkali, and set aside.

[0057] (3) Monomer dehydration crystallization: add alkali to release amine, add acid to neutralize the DMDAAC monomer solution after vacuum distillation until no water is evaporated, add 32mL water-carr...

Embodiment 2

[0063] The preparation method of high-purity DMDAAC monomer, concrete steps are as follows:

[0064] (1) Adding alkali to release amine: under the condition of stirring at room temperature, in the DMDAAC monomer aqueous solution (50wt%) that is placed in the 50g that is placed in the reactor, two-step method makes dripping the dilute sodium hydroxide aqueous solution that mass fraction is 5%, adjusts And maintain a certain pH value of 11.5, and then distill under reduced pressure at a temperature of 60°C to release the ammonium salt until the pH value of the distillate is constant at 7.3.

[0065] (2) Neutralize residual alkali: add 5% dilute hydrochloric acid aqueous solution to the DMDAAC monomer solution after amine release, adjust the pH value to 7.3, neutralize residual alkali, and set aside.

[0066](3) Monomer dehydration crystallization: add alkali to release amine, add acid to neutralize the DMDAAC monomer solution after vacuum distillation until no water is evaporate...

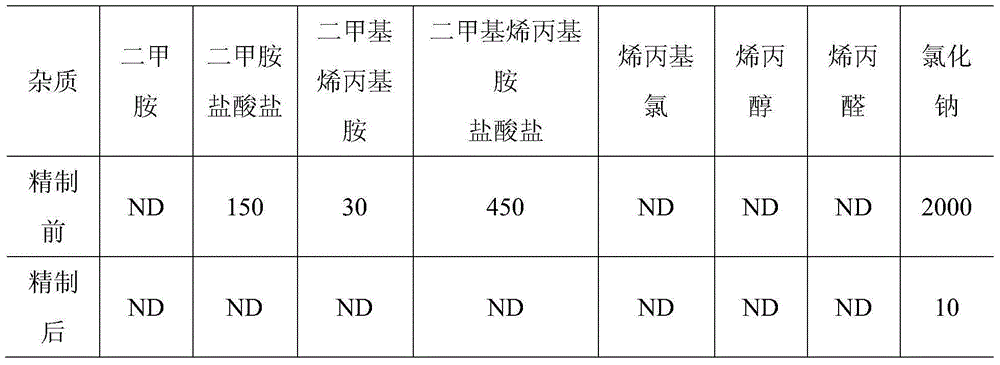

Embodiment 3

[0073] The preparation method of high-purity DMDAAC monomer, concrete steps are as follows:

[0074] (1) Add alkali to release amine: add dropwise 10% aqueous sodium hydroxide solution to the 50g two-step method DMDAAC monomer aqueous solution (60wt%) placed in the reactor under stirring at room temperature, adjust and maintain a certain pH value of 12.0 , and then distilled under reduced pressure at a temperature of 80°C to release the ammonium salt until the pH value of the distillate is constant at about 7.5.

[0075] (2) Neutralize residual alkali: add a small amount of 10% hydrochloric acid aqueous solution to the DMDAAC monomer solution after amine-releasing treatment, adjust the pH value to 7.5 to neutralize residual alkali, and then set aside.

[0076] (3) Monomer dehydration crystallization: add alkali to release amine, add acid to neutralize the DMDAAC monomer solution after vacuum distillation until no water is evaporated, add 300mL ethanol with water agent, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com