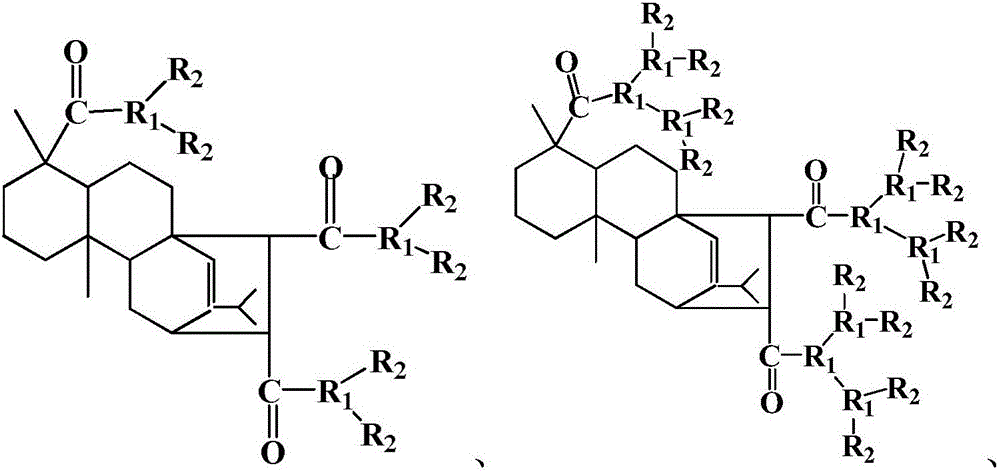

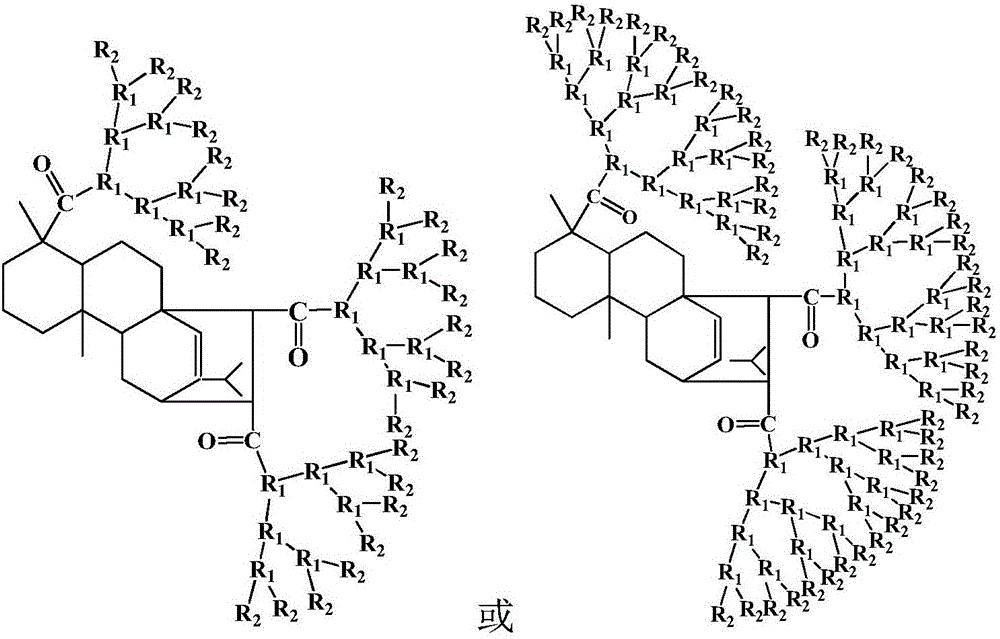

Abietyl hyper branched epoxy resin and preparation method and application thereof

An epoxy resin and rosin-based technology, which is applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., can solve the problem of low epoxy value, and achieve simple preparation process, reduced dependence, and low viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

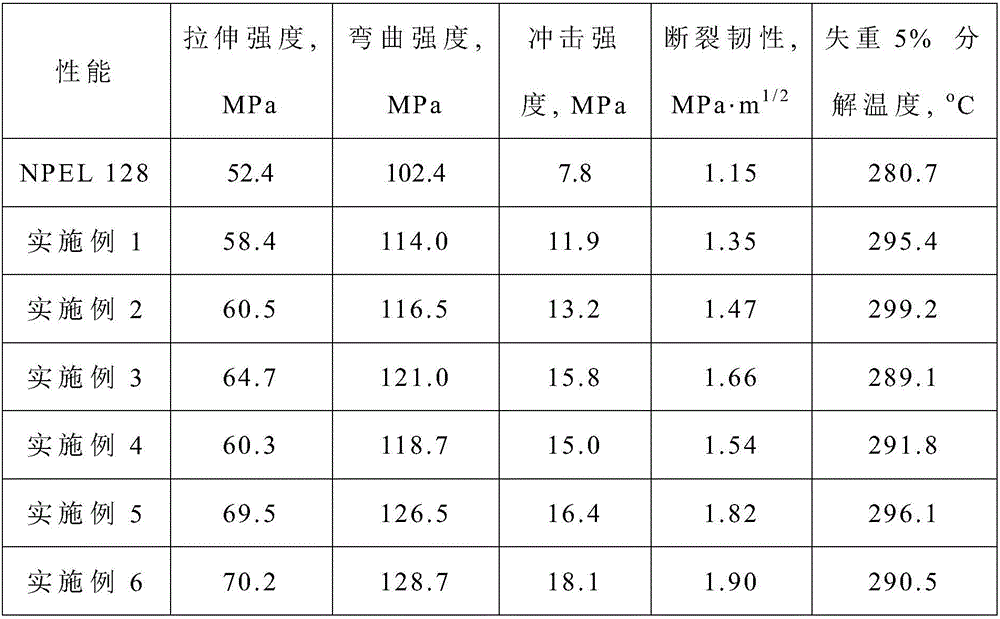

Examples

Embodiment 1

[0030] (a) React 40.00g of maleopimaric anhydride with 4.65g of ethylene glycol, 20g of xylene, and 0.06g of titanium tetraethoxide at 120°C for 6h, and then remove the xylene at 100°C under reduced pressure to obtain a carboxy-terminated abietyl hyperbranched polymer The ester (HBPE-1, containing 6 mol carboxyl groups per mole of HBPE-1), has a number average molecular weight of about 1340 g / mol.

[0031] (b) React 20.00g of HBPE-1, 41.21g of epichlorohydrin, and 0.04g of tetrabutylammonium bromide at 120°C for 3h, then remove unreacted epichlorohydrin under reduced pressure, and then add 24.00g of ethyl acetate, 4.46g of sodium hydroxide was reacted at 10°C for 7h. After the reaction, the layers were separated, the organic layer was aqueous to neutral and dried over anhydrous magnesium sulfate, and the ethyl acetate was removed under reduced pressure to obtain a rosin-based hyperbranched epoxy resin (HBEE -1, each mole of HBEE-1 contains 6 mol epoxy groups), the epoxy value ...

Embodiment 2

[0033] (a) React 40.00g maleopimaric anhydride with 5.58g ethylene glycol, 25g xylene, and 0.05g n-butyl titanate at 140°C for 5h, then remove the xylene under reduced pressure at 110°C to obtain a carboxy-terminated abietyl overbranch Polyester (HBPE-2, containing 12mol carboxyl groups per mole of HBPE-2), the number average molecular weight is about 2800g / mol.

[0034] (b) React 20.00g HBPE-2, 42.69g epichlorohydrin, and 0.05g tetrabutylammonium chloride at 110°C for 4 hours, then remove unreacted epichlorohydrin under reduced pressure, then add 20.00g tetrahydrofuran, 4.62g Sodium hydroxide, reacted at 0°C for 8 hours, separated after the reaction, the organic layer was aqueous to neutral, dried over anhydrous magnesium sulfate, and tetrahydrofuran was removed under reduced pressure to obtain rosin-based hyperbranched epoxy resin (HBEE-2, per The mole of HBEE-2 contains 12mol epoxy groups), the epoxy value is 0.32mol / 100g, and the viscosity is 740cp (25°C).

Embodiment 3

[0036] (a) React 40.00g maleopimaric anhydride with 5.92g ethylene glycol, 30g xylene, and 0.10g zinc acetate at 160°C for 4h, then remove xylene under reduced pressure at 120°C to obtain a carboxy-terminated abietyl hyperbranched polyester (HBPE-3, containing 24mol carboxyl groups per mole of HBPE-3), the number average molecular weight is about 4850g / mol.

[0037] (b) React 20.00g of HBPE-3, 48.01g of epichlorohydrin, and 0.18g of hexadecyltrimethylammonium bromide at 100°C for 5h, then remove unreacted epichlorohydrin under reduced pressure, and then add 25.00g Butyl acetate and 7.85g potassium hydroxide were reacted at 30°C for 5 hours. After the reaction, the layers were separated, the organic layer was aqueous to neutral, dried over anhydrous magnesium sulfate, and the butyl acetate was removed under reduced pressure to obtain a rosin-based hyperbranched ring Oxygen resin (HBEE-3, containing 24mol epoxy groups per mole of HBEE-3), the epoxy value is 0.30mol / 100g, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com