Polyether sulfonate anionic surfactant, and preparation method and application thereof

A technology of surfactant and sulfonate, which is applied in the field of polyether-type sulfonate anionic surfactant and its preparation, can solve the problem of low conversion rate of sulfamic acid sulfonation, unstable chemical properties, and non-compliance with green chemical industry And other problems, to achieve the effect of improving brightness and leveling, significant economic benefits, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

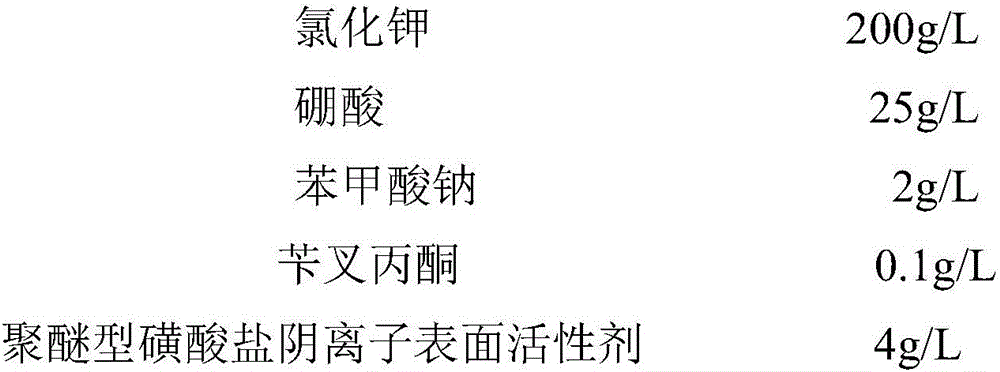

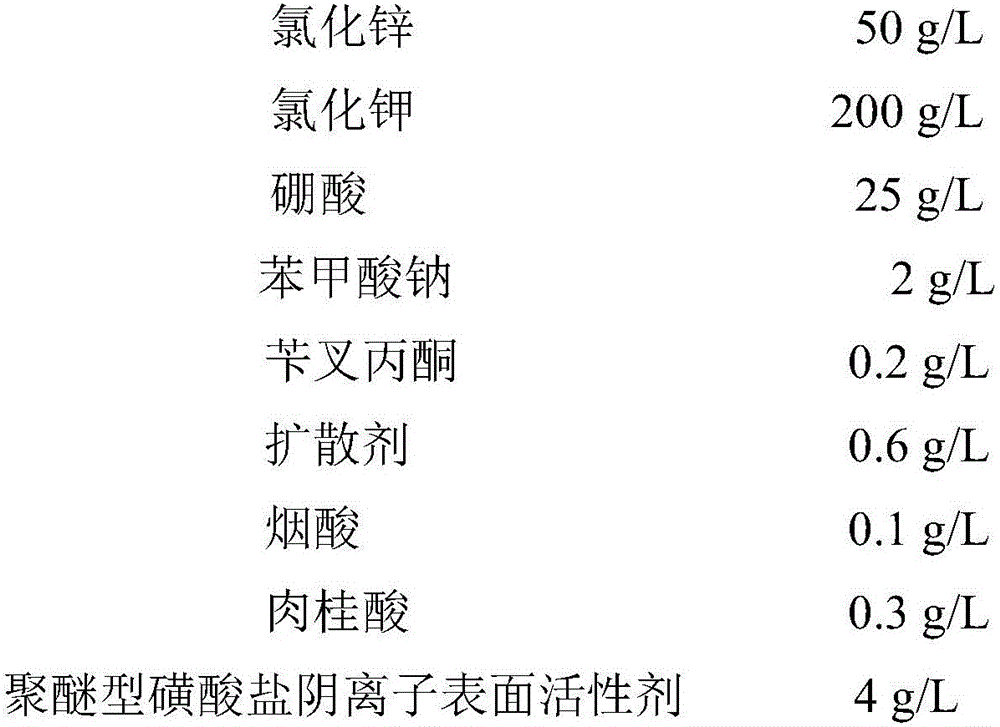

Examples

Embodiment 1

[0028] The preparation method of polyether type sulfonate anionic surfactant of the present invention:

[0029] Put 1mol fatty alcohol (C8 alcohol) polyether (n=6-24, m=2-10), 0.05mol cesium carbonate, 1.05mol potassium hydroxide (converted to 100% purity) into a three-necked flask, start stirring, and React at 40-50°C for 0.5h. Then dropwise add 1mol molten 1,3 propane sultone (melting point 40°C) into the flask, after 1h, the dropwise addition is completed, continue to stir at 40-50°C for 1h until the reaction is complete, and obtain a yellow to brownish yellow liquid material (n =6-15) or pasty material (n=20-24), yield>95%. The active matter content of the product is 75-85% as detected by the two-phase titration method, the water content is 1-5% as detected by the Karl Fischer moisture analyzer, and the pH is 9-12.

Embodiment 2

[0031] The preparation method of polyether type sulfonate anionic surfactant of the present invention:

[0032] With 1mol fatty alcohol (C12-14 alcohol) polyether (n=6-24, m=1-10), 0.05mol tetrabutylammonium bromide, 0.05mol catalyst carbon, 1.05mol potassium hydroxide (conversion is 100% purity) into a three-necked flask, start stirring, and react at 40-50°C for 0.5h. Then dropwise add 1mol molten 1,3 propane sultone (melting point 40° C.) into the flask, and after 1 hour, the dropwise addition is completed, and continue to stir at 40-50° C. for 1 hour until the reaction is complete, and a yellow to brownish yellow paste material ( n=20-24), the yield>95%. The active matter content of the product is 75-85% as detected by the two-phase titration method, the water content is 1-5% as detected by the Karl Fischer moisture analyzer, and the pH is 9-12.

Embodiment 3

[0034] The preparation method of polyether type sulfonate anionic surfactant of the present invention:

[0035] Put 1mol naphthol polyether (n=3-24, m=5-15), 0.05mol DBU, 0.05mol catalyst carbon, 1.05mol potassium hydroxide (converted to 100% purity) into a three-necked flask, start stirring, at 40 React at -50°C for 0.5h. Then dropwise add 1mol molten 1,3 propane sultone (melting point 40° C.) into the flask, and after 1 hour, the dropwise addition is completed, and continue to stir at 40-50° C. for 1 hour until the reaction is complete, and a yellow to brownish yellow paste material ( n=10-24), the yield>95%. The active matter content of the product is 75-85% as detected by the two-phase titration method, the water content is 1-5% as detected by the Karl Fischer moisture analyzer, and the pH is 9-12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com