A kind of preparation and application method of water-based modified graphene slurry

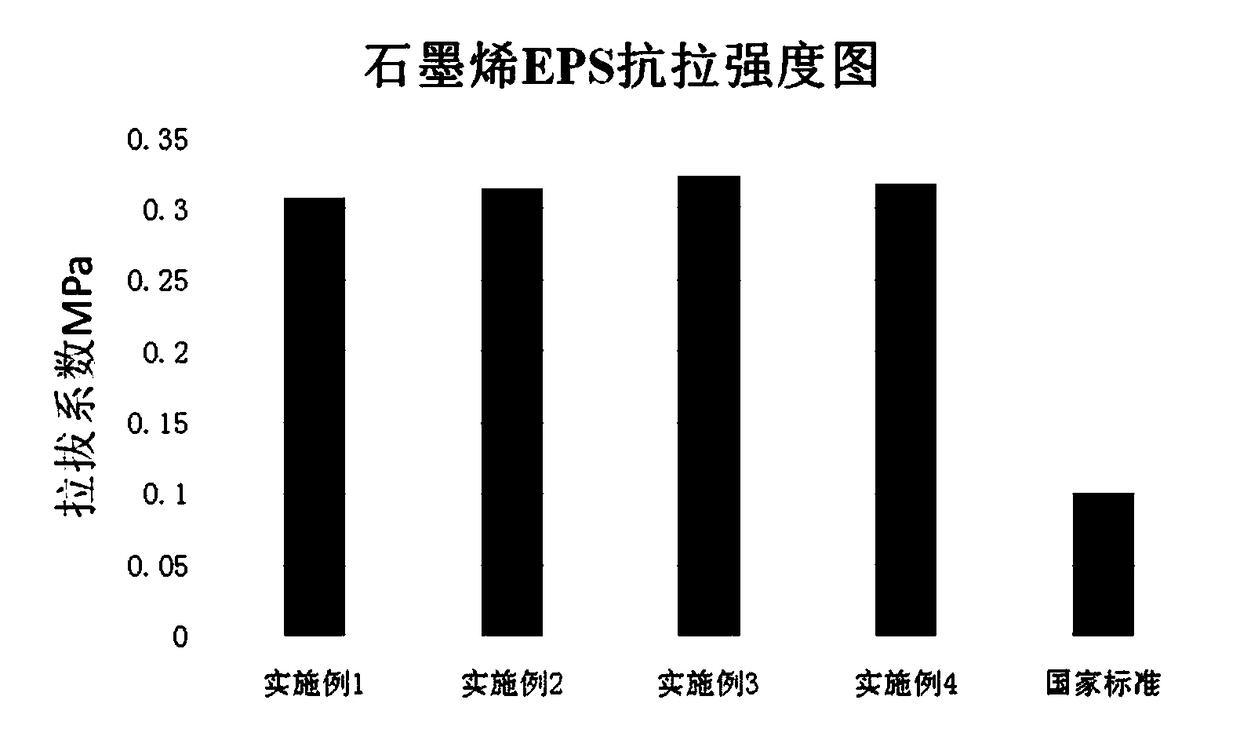

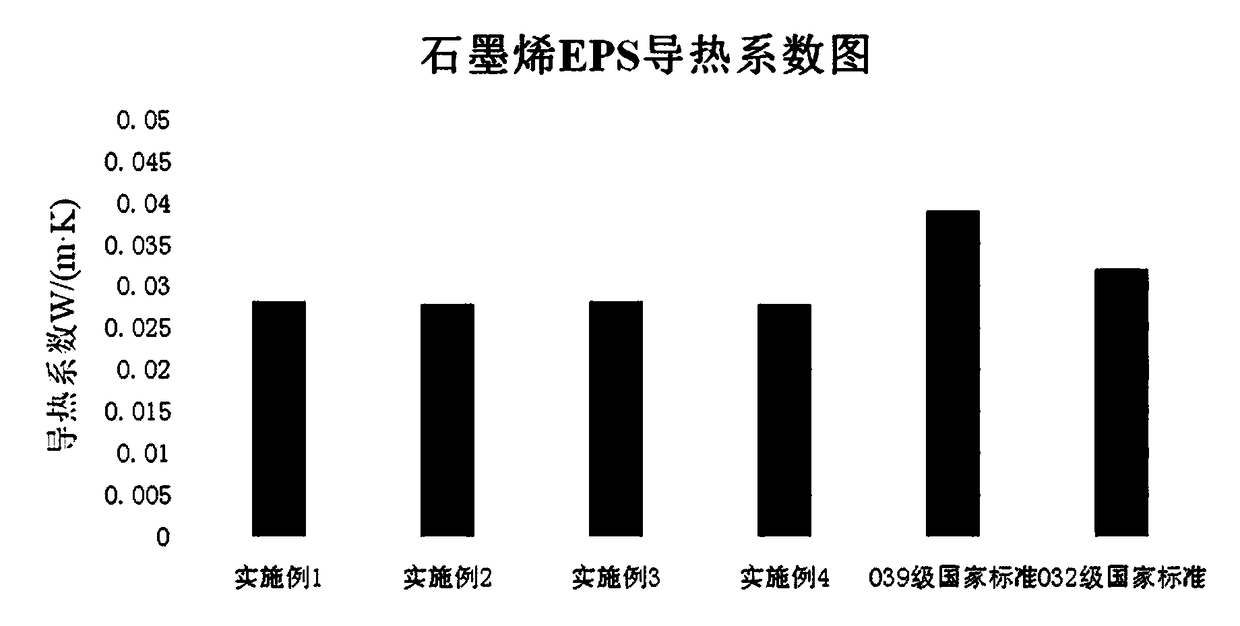

A water-based modification, graphene technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of restricting the application of EPS finished products, increasing the viscosity of the polymerization system, and prolonging the polymerization reaction time. Achieve the effect of solving the polymerization inhibition effect, improving the thermal insulation performance, and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of modified graphene: 50g of graphene powder and 2.5g of sodium hexadecylbenzenesulfonate were ultrasonically pre-dispersed in deionized water, and then 2.5g of silane coupling agent KH550 and 5g of active calcium phosphate were added to modify graphene. Stirring and shearing dispersion for 2 hours, after modification, filter and dry to obtain modified graphene powder.

[0032] (1) Pre-dispersion: Proportioning by weight 90wt% deionized water, 1wt% polyethylene glycol 400 (400 is the molecular weight, the same below), 1wt% polyethylene wax, 5wt% ethylene glycol, added to the high-speed shear In the grinding machine, carry out pre-dispersion for 10 minutes, and control the speed at 5000r / min.

[0033] (2) Modified graphene slurry intermediate: gradually add 3wt% modified graphene powder into the pre-dispersion liquid, stir for 10 minutes until fully dispersed, and control the speed at 5000r / min.

[0034] (3) Grinding of modified graphene slurry: Finally, per...

Embodiment 2

[0037]Preparation of modified graphene: 50g of graphene powder and 0.5g of sodium dodecylbenzenesulfonate were pre-dispersed in deionized water by ultrasonic, and then 2g of silane coupling agent KH560 and 3g of active calcium phosphate were added to modify graphene Disperse, stir and shear to disperse for 2 hours, filter and dry after modification to obtain modified graphene powder.

[0038] (1) Pre-dispersion: Proportioning by weight 75.5wt% deionized water, 5wt% polyethylene glycol 800, 2wt% EAA, 0.5wt% EMAA, 4wt% ethanol, 2wt% glycerol, 1wt% n-butanol, add Into the high-speed shearing mill, carry out pre-dispersion for 20min, the speed control is 3500r / min.

[0039] (2) Modified graphene slurry intermediate: gradually add 10wt% modified graphene powder to the pre-dispersion liquid, stir for 20 minutes until fully dispersed, and control the speed at 3500r / min.

[0040] (3) Grinding of modified graphene slurry: Finally, high-speed shear grinding of graphene slurry is carrie...

Embodiment 3

[0043] Preparation of modified graphene: Ultrasonic pre-dispersion of 50 g of graphene powder and 1.5 g of sodium octadecylbenzenesulfonate in deionized water, and then adding 0.5 g of silane coupling agent KH570 and 4 g of active calcium phosphate to modify graphene Stirring and shearing dispersion for 2 hours, after modification, filter and dry to obtain modified graphene powder.

[0044] (1) Pre-dispersion: proportioning by weight 62wt% deionized water, 3wt% polyethylene glycol 2000, 5wt% polyethylene glycol 6000, 3wt% EVA, 2wt% EMA, 3wt% ethanol, 2wt% ethyl acetate , 5wt% propylene glycol, join in the high-speed shear grinder, carry out pre-dispersion 25min, speed control is 3000r / min.

[0045] (2) Modified graphene slurry intermediate: gradually add 15wt% modified graphene powder to the pre-dispersion liquid, stir for 25 minutes until fully dispersed, and control the speed at 3000r / min.

[0046] (3) Grinding of modified graphene slurry: Finally, high-speed shear grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com