Method for preparing active peptide from waste fermented grains

A technology of active peptides and white wine, which is applied in the direction of fermentation, can solve the problems that have not been reported, and achieve the effect of simple process, small molecular weight and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

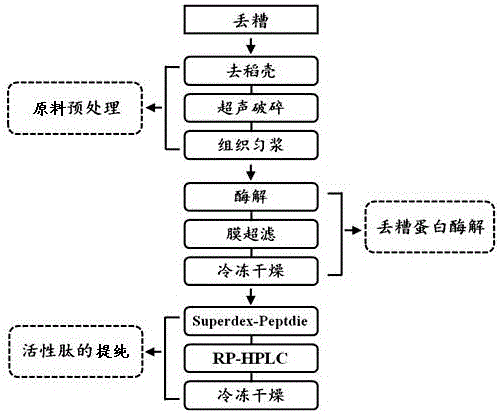

[0019] 1) Raw material pretreatment: Take the distilled grains and add 8 times the volume of water to fully stir for 5 minutes, use gauze to filter out the suspended rice husk, and the remaining mixture is ultrasonically crushed (20 KHz) 5 times every 2 minutes for a total of 10 minutes, and tissue Homogenize for 20 min.

[0020] 2) Enzymatic hydrolysis of waste protein: adjust the pH value of the homogenate in step (1) to 5.5 with 1 mol / L hydrochloric acid, preheat at 50 °C for 5 minutes, add 6% (w / w) papain, and perform enzymatic hydrolysis at 50 °C for 4 h, inactivate the enzyme at 80°C for 10 min to terminate the reaction, and perform ultrafiltration of the final enzymatic hydrolysis product on a 3 kDa membrane, collect the extramembrane liquid and freeze-dry to obtain the active peptide, measure the molecular weight distribution ratio and biological activity; the yield of the active peptide is 11- 12%;

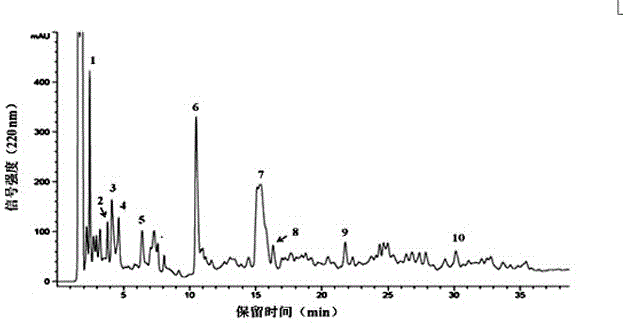

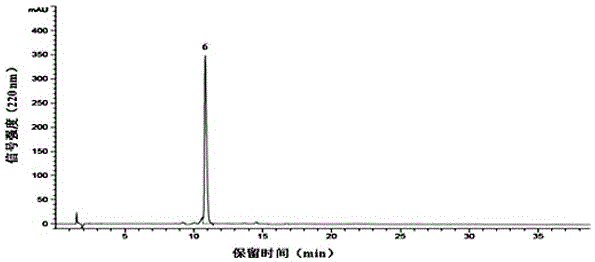

[0021] 3) Purification of active peptides: Dissolve the above activ...

Embodiment 2

[0023] 1) Raw material pretreatment: Take the distilled grains and add 8 times the volume of water to stir for 5 minutes, filter the suspended rice husks with gauze, and ultrasonically break the remaining mixture (25 KHz) 10 times every 2 minutes for a total of 20 minutes, and organize Homogenize for 25 min.

[0024] 2) Enzymatic hydrolysis of discarded waste protein: adjust the pH value of the homogenate to 6.0 with 1 mol / L hydrochloric acid, preheat at 50 °C for 5 min, add 6% (w / w) papain, enzymatically hydrolyze at 60 °C for 4 h, at 80 °C The reaction was terminated by inactivating the enzyme at ℃ for 15 minutes, and the final enzymatic hydrolysis product was subjected to 3 kDa membrane ultrafiltration, and the extramembrane fluid was collected to obtain the active peptide after freeze-drying, and the molecular weight distribution ratio and biological activity were determined; the yield of the active peptide was 11-12%;

[0025] 3) Purification of active peptides: Dissolve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com