Ternary cathode material for lithium ion battery and preparation method thereof

A lithium-ion battery and cathode material technology, applied in the field of electrochemistry, can solve the problems of high residual alkali on the surface, high cost, and the processing performance of high-nickel ternary materials cannot be improved, so as to improve the surface alkalinity and reduce the input cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

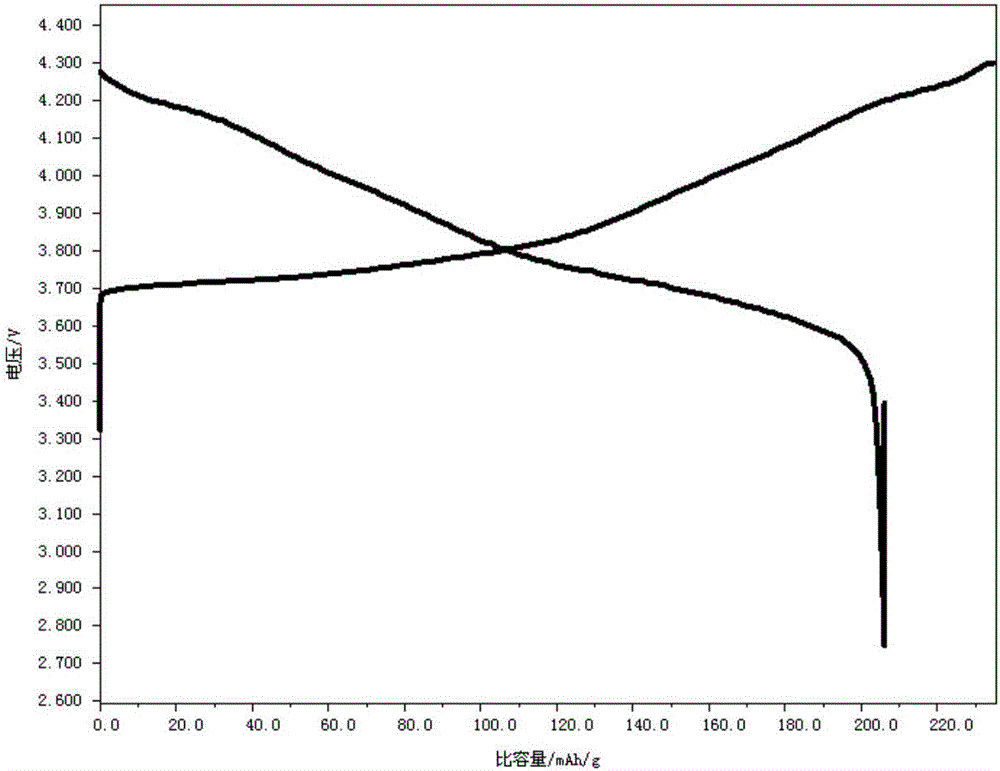

Embodiment 1

[0039] A kind of preparation method of lithium-ion battery ternary cathode material:

[0040] S1. Add D50=12μm high nickel nickel cobalt manganese hydroxide Ni 0.8 co 0.1 mn 0.1 (OH) 2 and lithium hydroxide are mixed in a dry mixer according to the molar ratio Li:(Ni+Co+Mn)=1.04 to obtain the mixed material;

[0041] S2. Raise the mixed material to 500°C at a heating rate of 5°C / min, and keep it at 500°C for 5 hours, then raise it to 825°C at a heating rate of 5°C / min, and keep it at 825°C for 15 hours. Conducted in 95% oxygen atmosphere;

[0042] S3. Cool the sintered material to room temperature, then pulverize and sieve to obtain a semi-finished product;

[0043] S4. get 3kg semi-finished product and 60g low nickel nickel cobalt manganese hydroxide Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 (Particle size D50=1μm) Carry out coating treatment in the high-speed mixer according to the coating amount of 2%, first carry out mixing and stirring at low speed 700r / min for 30 minutes, and...

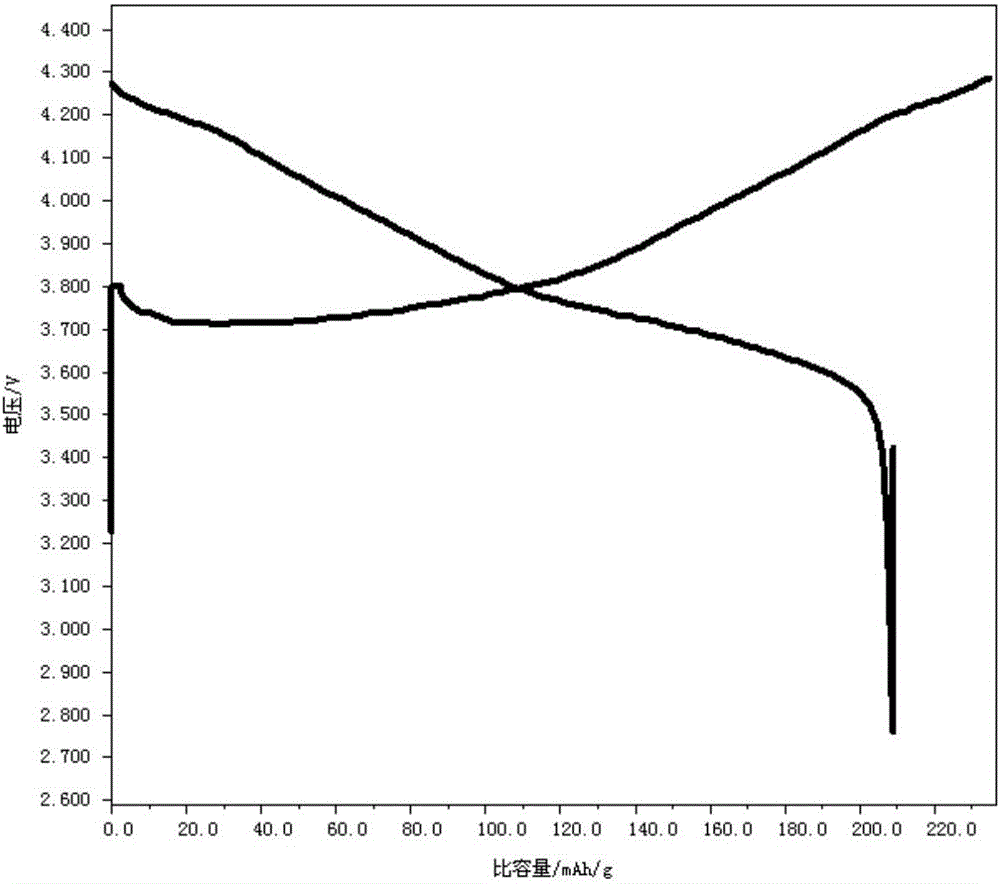

Embodiment 2

[0049] A kind of preparation method of lithium-ion battery ternary cathode material:

[0050] S1. D50=14μm nickel cobalt aluminum hydroxide Ni 0.8 co 0.15 Al 0.05 (OH) 2 and lithium hydroxide are mixed in a dry mixer according to the molar ratio Li:(Ni+Co+Mn)=1.02 to obtain the mixed material;

[0051] S2. Sintering the mixed material for 20 hours at 800°C in a 100% oxygen atmosphere;

[0052] S3. Cool the sintered material to room temperature, then pulverize and sieve to obtain a semi-finished product;

[0053] S4. Get 3kg semi-finished product and 90g low nickel nickel cobalt manganese hydroxide Ni 0.2 co 0.4 mn 0.4 (OH) 2 (Particle size D50=1.5μm) Carry out coating treatment in high-speed mixer according to the coating amount of 3%, carry out mixing and stirring at low speed 700r / min for 30 minutes, then carry out high-speed shearing at high speed 1400r / min for 15 minutes to obtain coating good semi-finished products;

[0054] S5. Sinter the coated semi-finished p...

Embodiment 3

[0057] A kind of preparation method of lithium-ion battery ternary cathode material:

[0058] S1. D50=10μm nickel cobalt manganese hydroxide Ni 0.6 co 0.2 mn 0.2 (OH) 2 and lithium hydroxide are mixed in a dry mixer according to the molar ratio Li:(Ni+Co+Mn)=1.06 to obtain the mixed material;

[0059] S2. Sintering the mixed material at 900° C. in an oxygen atmosphere of 90% for 8 hours;

[0060] S3. Cool the sintered material to room temperature, then pulverize and sieve to obtain a semi-finished product;

[0061] S4. get 3kg semi-finished product and 30g low nickel nickel cobalt manganese hydroxide Ni 0.4 co 0.2 mn 0.4 (OH) 2 (Particle size D50=0.5μm) according to the coating amount of 1%, carry out coating treatment in the high-speed mixer, first carry out mixing and stirring at low speed 700r / min for 60 minutes, and then carry out high-speed shearing at high speed 1400r / min for 10 minutes to obtain coating good semi-finished products;

[0062] S5. Sinter the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com