Preparation method for high dispersibility Cu based cerium oxide composite catalyst

A technology of composite catalyst and cerium oxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, carbon monoxide, etc., can solve the problem of unsuitable reverse water gas shift reaction of copper-based catalyst, poor thermal stability, High reaction temperature and other problems, to achieve the effect of good industrial application prospects, good thermal stability, and simple parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

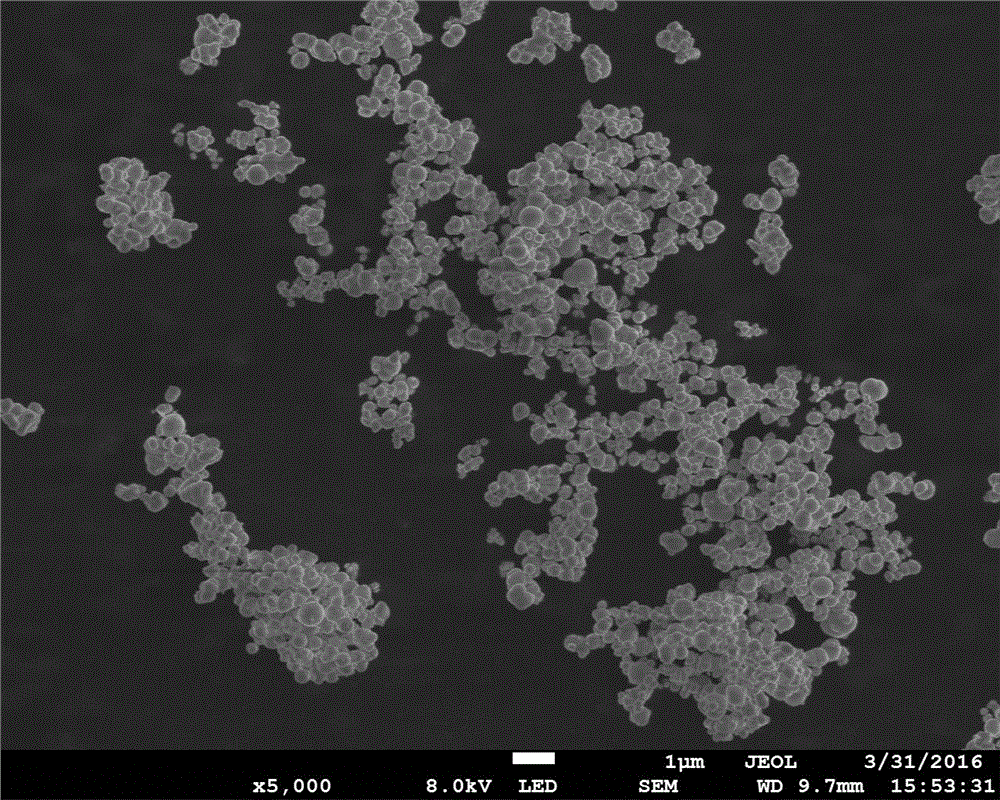

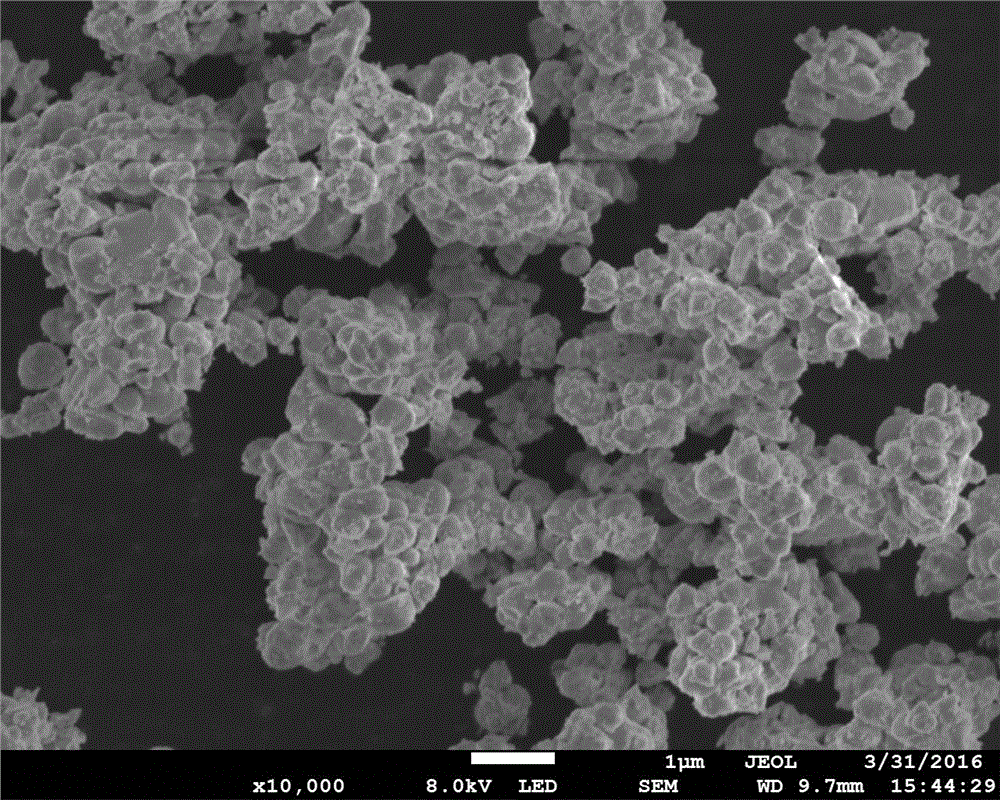

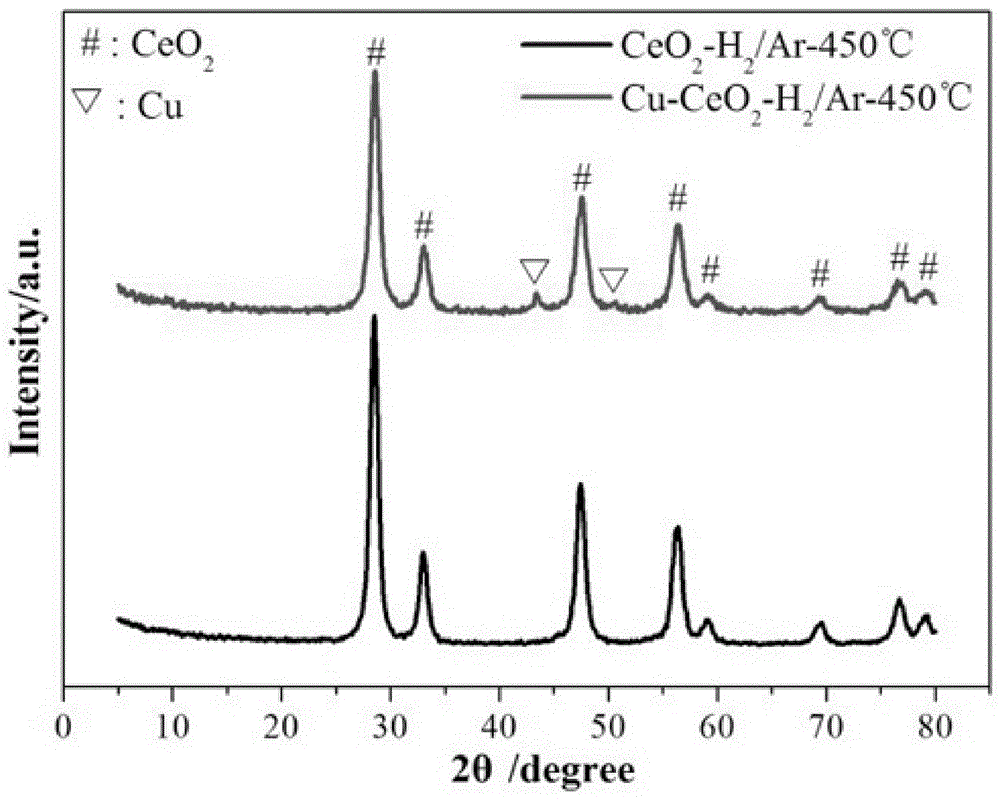

[0027] This embodiment discloses a method for preparing a highly dispersed Cu-based cerium oxide composite catalyst, which mainly includes the following steps:

[0028] (1) Prepare 0.1mol / L cerium nitrate solution and 0.4mol / L 2-methylimidazole solution respectively, pour the 2-methylimidazole solution into the cerium nitrate solution during the stirring process, and stop after the solution is evenly mixed stir;

[0029] (2) Stand at 20°C for 24 hours, then perform centrifugation, wash and dry to obtain the precursor;

[0030] (3) The precursor obtained in step 2 and copper nitrate were solid-phase mechanically ground, and methanol was used as a solvent to gradually volatilize during the grinding process to form a composite catalyst precursor of highly dispersed Cu-based cerium oxide, by mass fraction Calculated, the content of copper in the composite catalyst precursor is 10%;

[0031] (4) Put the composite catalyst precursor into the tube furnace, under H 2 Calcining for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com