Method for preparing composite adsorption material used for absorbing rubidium and cesium ions

A composite adsorption material and ion technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as fragility, waste of adsorbents, and large volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

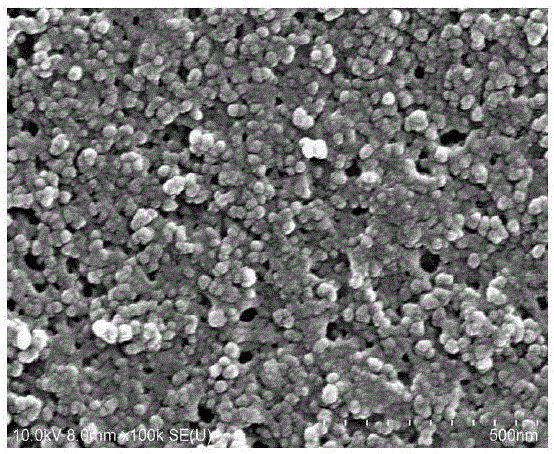

[0010] Example 1: Preparation of polydopamine / ferric ferrocyanide composite adsorption functional film

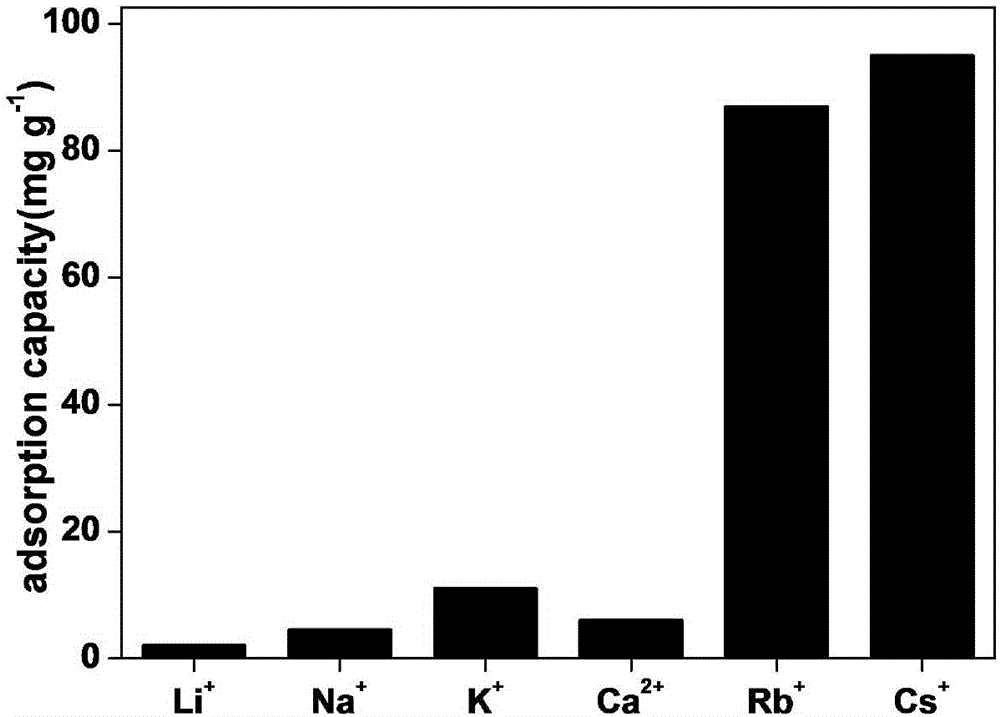

[0011] Dissolve dopamine (PODA) in Tirs-HCl buffer solution (pH8.5), then put the polyethersulfone porous membrane into the solution to polymerize for 10h, wash and dry; then put the above membrane in K 4 Fe(CN) 6 Fully soaked in the solution for 24 hours, the solution starts to be colorless, and turns light yellow after a period of time, indicating that ferrocyanide crystal nuclei have been formed. Rinse the membrane and put in 0.1M FeCl 3 The solution was grown, and after 24 hours, it was taken out, washed and dried to obtain polydopamine / ferric ferrocyanide composite adsorption functional film ( figure 1 ). The prepared adsorption functional membrane was used for 50ml 10ppm Cs respectively + , Rb + , Li + 、Na + 、K + and Ca 2+ Adsorption of the solution, for Rb + The adsorption capacity reaches 87mg / g, for Cs + The adsorption capacity reaches 95mg / g, and it has ...

Embodiment 2

[0012] Embodiment 2: the preparation of polycaffeic acid / copper ferricyanide composite adsorption sponge

[0013] Put the polyurethane sponge into the caffeic acid solution and irradiate it with γ-rays for 1 h to obtain the polyurethane sponge grafted with polycaffeic acid on the surface; then put the sponge into Cu 2+ Fully soak in the solution, take out and wash after 6 hours, and then put in 0.05M Fe(CN) 6 3- Nucleation and growth in the solution, repeating the above process can increase the thickness of the adsorption layer, and finally obtain polycaffeic acid / copper ferricyanide composite adsorption sponge, which is used for 50ml 10ppm Cs + The solution is adsorbed, and the adsorption capacity reaches 105mg / g.

Embodiment 3

[0014] Example 3: Preparation of polycatechin / ammonium phosphotungstate composite adsorption resin

[0015] Put the polystyrene resin (PS-DVB) into the catechin solution for adsorption for 6 hours, then immerse the resin in concentrated sulfuric acid for cross-linking for 1 hour to obtain a resin coated with polycatechin on the surface; immerse the resin in 0.1M phosphotungstic acid Adsorb in the aqueous solution for 8 hours, take it out and dry it, then add 0.05M NH 4 Nucleation and growth were carried out in Cl solution, and finally polycatechin / ammonium phosphotungstate composite adsorption resin was obtained, which were used in 50ml 10ppm Rb + and Cs + The solution is adsorbed, and the adsorption capacity reaches 80mg / g and 90mg / g respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com