High-simulation tissue engineering nerve repairing scaffold and making method thereof

A technology for simulating tissue and nerve repair, applied in the field of nerve repair tissue engineering, can solve problems such as the inability to precisely control pore size, spatial distribution and spatial structure, achieve good biocompatibility and biological activity, mild reaction conditions, and process technology. mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

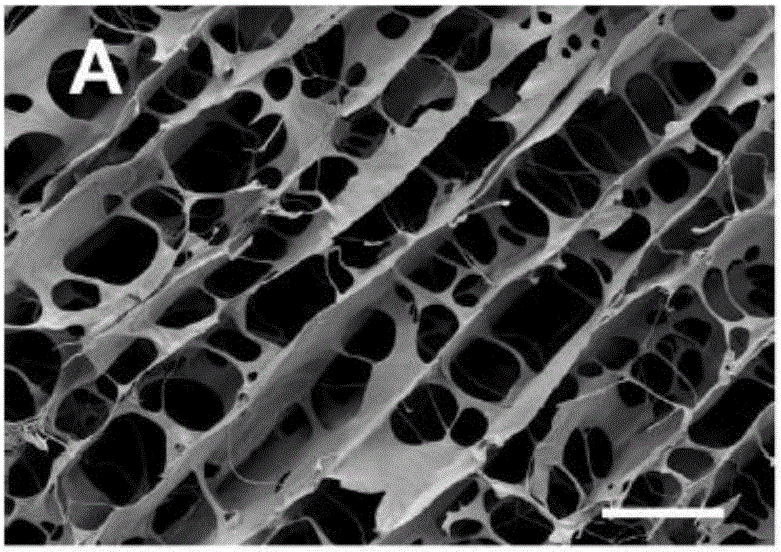

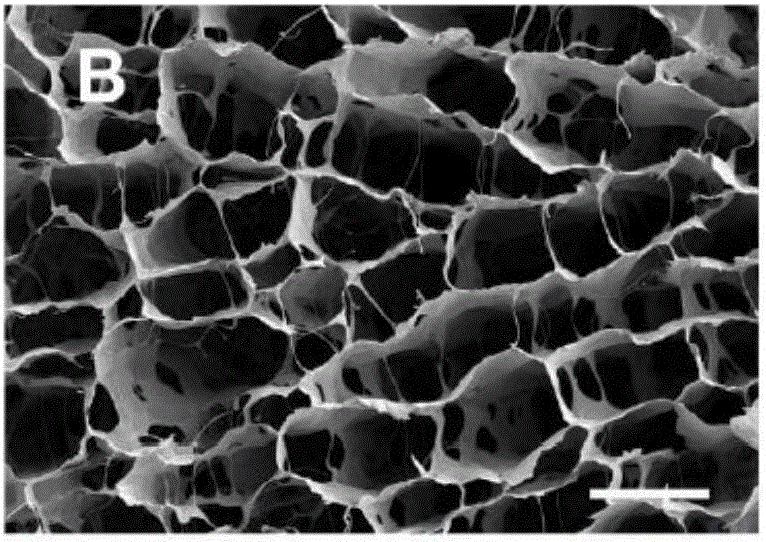

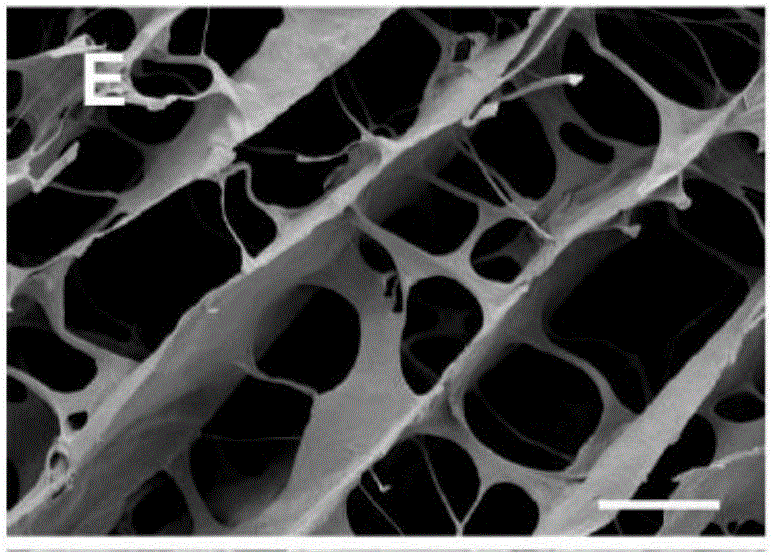

Image

Examples

preparation example Construction

[0023] A preparation method of a highly simulated tissue engineering nerve repair scaffold provided by the present invention comprises:

[0024] Preparation of Type I Collagen-Chitosan Suspension: Weigh Type I Collagen and Chitosan respectively according to the mass ratio of 1-10:1. Dissolve type I collagen in 0-4 mg / ml acetic acid or malonic acid solution for 2 hours, then stir in a constant temperature environment at 4°C to make a suspension; add chitosan to 0-4 mg / ml acetic acid Or fully dissolved in malonic acid solution, mix the two suspensions and keep stirring at a constant temperature of 4°C, fully mix to make type Ι collagen-chitosan suspension, and vacuumize and stand for 12 hours.

[0025] Injection molding and cold shower treatment: inject type Ι collagen-chitosan suspension into the silicone tube and seal the two ends, then slowly immerse the molded sample in the deep-low temperature cold shower (liquid nitrogen), enter the speed control 1×10 -6 m / s~1×10 -4 m / s...

Embodiment 1

[0038] Embodiment 1 provides a kind of preparation method of high-simulation tissue engineering nerve repair support, carries out according to the following steps:

[0039] 1. Preparation of Type I Collagen-Chitosan Suspension: Weigh Type I Collagen and Chitosan in a mass ratio of 4:1. Dissolve type I collagen in 1.5mg / ml malonic acid solution for 2 hours, then stir in a constant temperature environment at 4°C to make a suspension; add chitosan to 1.5mg / ml malonic acid solution Fully dissolve, mix the two suspensions and keep stirring at a constant temperature of 4°C, fully mix to form a type Ι collagen-chitosan gel-like suspension, vacuumize and stand for 12 hours;

[0040] 2. Injection molding and improved cold leaching treatment: Inject the suspension into the silicone tube and seal both ends, then slowly immerse the molded sample in the deep low temperature cold leaching agent (liquid nitrogen), and the entry speed is controlled to 2×10 -5 m / s, carry out gradient cold sho...

Embodiment 2

[0045] Embodiment 2 provides a kind of preparation method of highly simulated tissue engineered nerve repair scaffold, according to the method of embodiment 1, difference is: according to type I collagen protein and chitosan mass ratio is 10:1, adopts malonic acid The solution concentration is 0.5mg / mL, and the gradient cold shower speed is controlled at 1×10 -6 m / s, the raw material composition of the protective film is 100% polycaprolactone, the loading voltage used for electrospinning is 5kV, the feed rate of electrospinning is 0.5mL / h, and the mass concentration of genipin solution used is 0.5%. Nepin cross-linking time is set to 12h. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com