Preparation method of bio-based medical auxiliary material

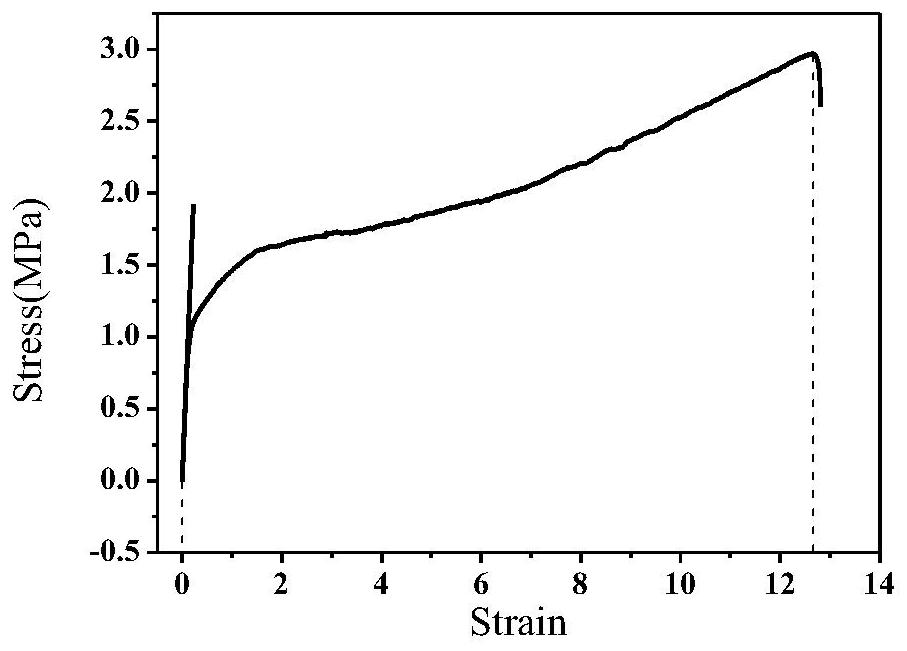

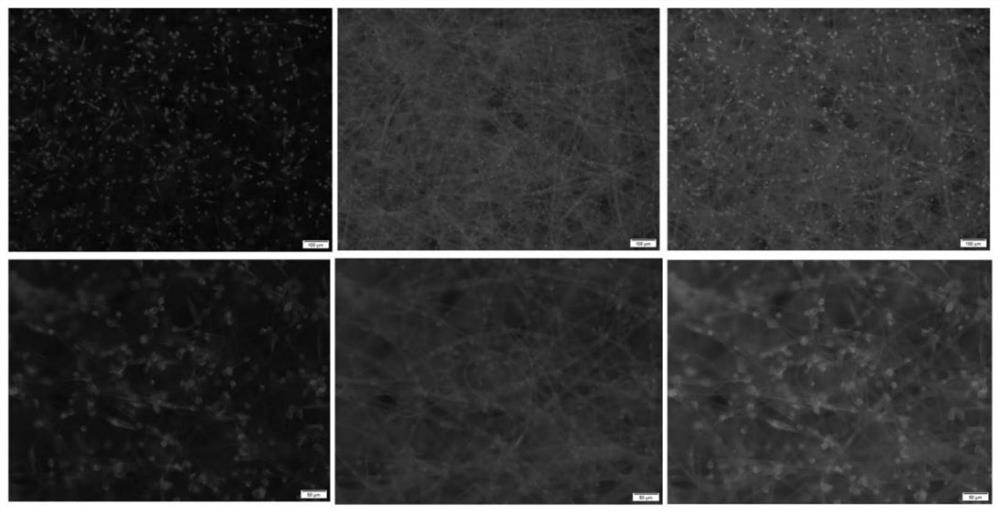

A bio-based, manufacturing method technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of low elongation at break, poor thermal stability, difficult processing, etc. Good sex, no inflammatory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

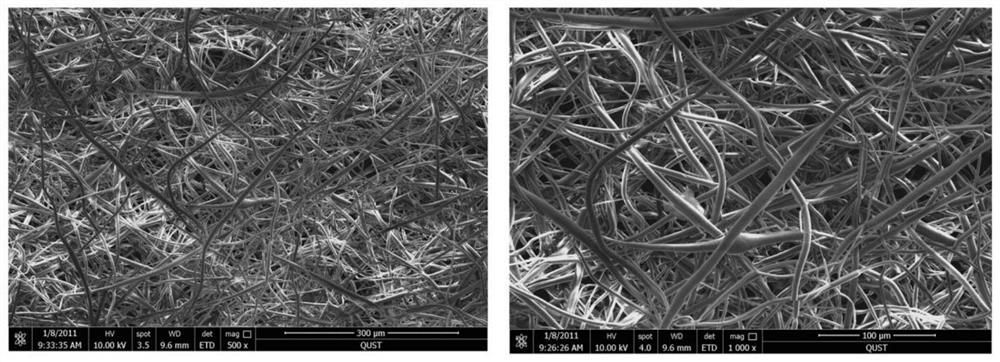

[0025] The preparation of the film is as follows: the polyester material is dissolved in chloroform at room temperature to obtain a 20wt% polyester-chloroform polymer mixture, and the mixture is stirred overnight on a magnetic stirrer to obtain a uniform and transparent high-molecular mixture. Molecular solution; place the polymer solution in the feeding syringe of the electrospinning equipment, and feed it at a feeding rate of 10 μl / min; adjust the distance between the needle tip of the syringe and the static grounding plate to 20 cm; adjust the spinning ambient temperature 30°C; turn on the high-voltage power supply and the feeding syringe pump, adjust the voltage to 20kV, adjust the air flow rate of the environment to 0-5m2 / min, cover the tin platinum paper on the static ground plate, and then obtain the electrospun fiber film, the film thickness 100-300μm.

[0026] Carefully remove the electrospun fiber film from the tinfoil, place it in a vacuum oven for annealing and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com