Glutamic acid modified chitosan adsorbent as well as preparation method and application thereof

A technology of chitosan and glutamic acid, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of high ammonia nitrogen wastewater environment, high synthesis cost, low extraction and distribution of metal ions, etc. Achieve the effects of high separation and enrichment efficiency, reduced processing costs, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

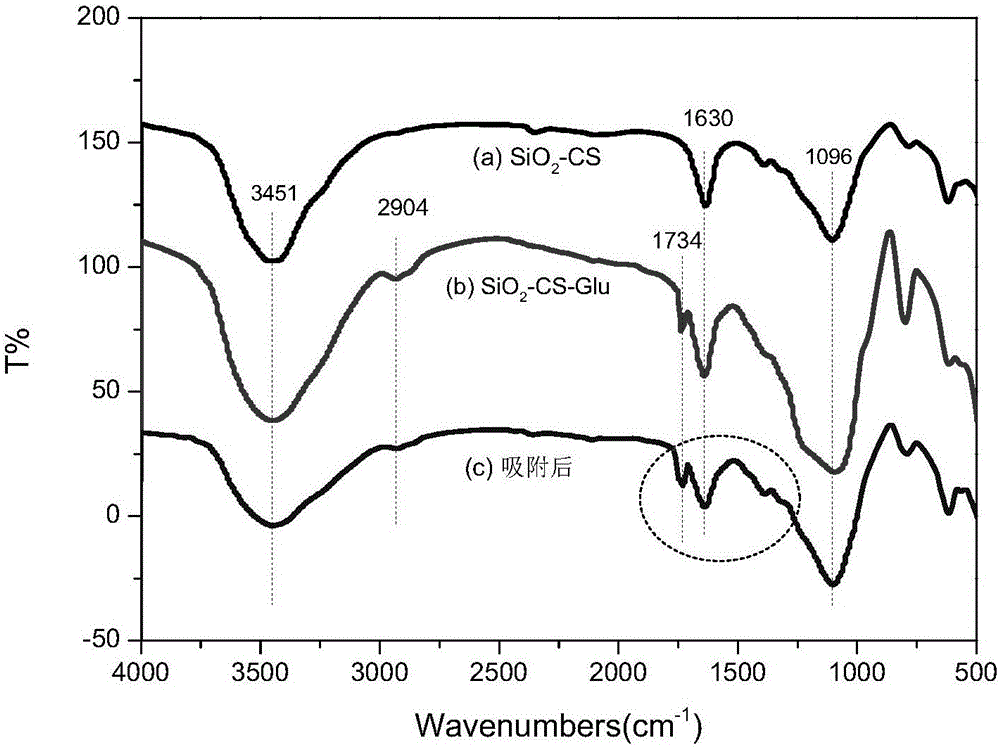

[0032] (1) Preparation method

[0033] 1) Chitosan: Take an appropriate amount of crab shells, grind them to obtain crab shell powder, add 5% HCl solution and soak for 12 hours to remove soluble impurities. After filtering and drying, add 40% NaOH solution and react at 100° C. for 7 hours to obtain white solid chitosan CS.

[0034] 2) Dissolve 2g of CS in 100mL of 2% acetic acid solution by volume, add 30mL TEOS and stir for about 30min; add the mixture into 200mL of 3% ammonia by volume, stir for 24h, filter with Wash with ethanol until neutral, dry in vacuum for 24h, and obtain the matrix material CS-SiO 2 ;

[0035] 3) Take 1g CS-SiO 2 Add to ethanol aqueous solution (v:v=1:1), then add 10mL epichlorohydrin, reflux at 70°C for 3h, cool, filter, wash with water and ethanol, and dry to obtain intermediate product I;

[0036] 4) Dissolve 2.5g of glutamic acid in 50mL, 1.5mol / L sodium carbonate solution, add 0.5g of intermediate product I, reflux at 80°C for 24h, cool, filt...

Embodiment 2

[0041] (1) Preparation method

[0042] 1) chitosan: with embodiment 1.

[0043]2) Dissolve 2g of CS in 100mL of 2% acetic acid solution by volume, add 30mL TEOS and stir for about 30min; add the mixture into 200mL of 3% ammonia by volume, stir for 24h, filter with Wash with ethanol until neutral, dry in vacuum for 24h, and obtain the matrix material CS-SiO 2 ;

[0044] 3) Take 1g CS-SiO 2 Add to ethanol aqueous solution (v:v=1:1), then add 15mL epichlorohydrin, reflux at 70°C for 3h, cool, filter, wash with water and ethanol, and dry to obtain intermediate product I;

[0045] 4) Dissolve 2.5g of glutamic acid in 50mL, 1.5mol / L sodium carbonate solution, add 0.5g of intermediate product I, reflux at 80°C for 24h, cool, filter with suction, wash with distilled water until neutral, and dry to obtain Glutamic acid modified chitosan adsorbent SiO 2 -CS-Glu.

[0046] (2) Results

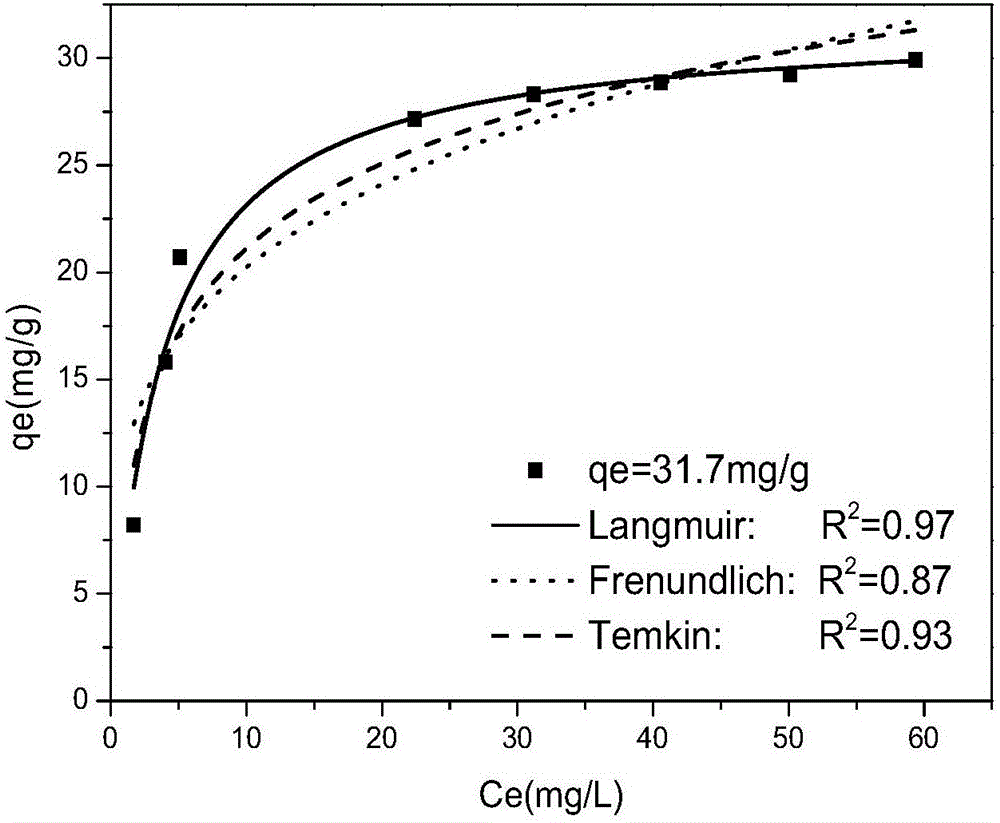

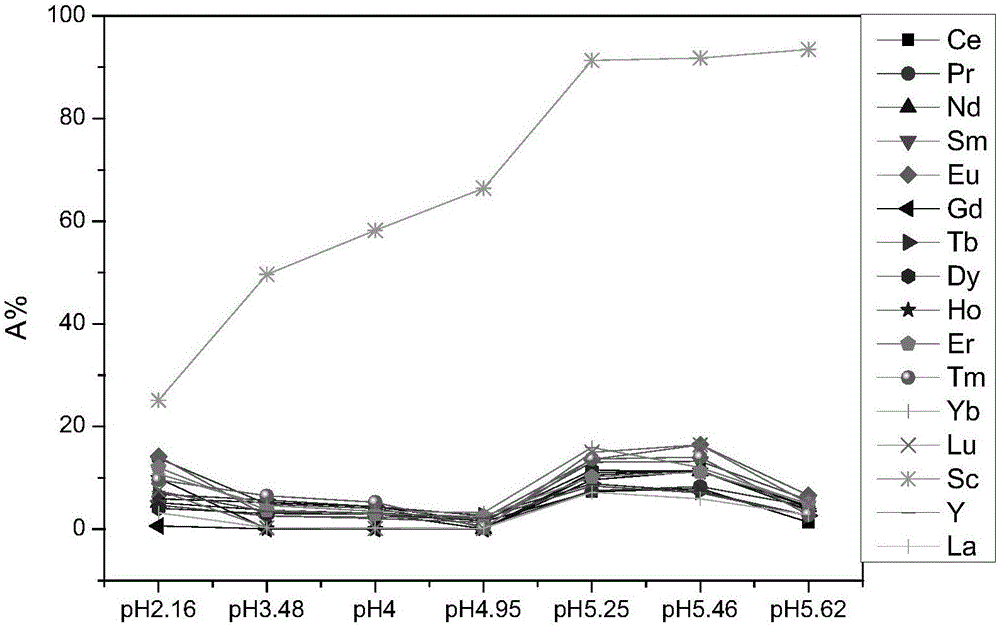

[0047] The adsorbent performs vibration adsorption on a 20 ppm scandium solution with pH=4 at a ...

Embodiment 3

[0049] (1) Preparation method

[0050] 1) chitosan: with embodiment 1.

[0051] 2) Dissolve 2g of CS in 100mL of 2% acetic acid solution by volume, add 30mL TEOS and stir for about 30min; add the mixture into 200mL of 3% ammonia by volume, stir for 24h, filter with Wash with ethanol until neutral, dry in vacuum for 24h, and obtain the matrix material CS-SiO 2 ;

[0052] 3) Take 1g CS-SiO 2 Add to ethanol aqueous solution (v:v=1:1), then add 10mL epichlorohydrin, reflux at 70°C for 3h, cool, filter, wash with water and ethanol, and dry to obtain intermediate product I;

[0053] 4) Dissolve 5g of glutamic acid in 50mL, 1.5mol / L sodium carbonate solution, add 0.5g of intermediate product I, reflux at 80°C for 24h, cool, filter with suction, wash with distilled water until neutral, and dry to obtain gluten Amino Acid Modified Chitosan Adsorbent SiO 2 -CS-Glu.

[0054] (2) Results

[0055] The adsorbent performs vibration adsorption on a 20 ppm scandium solution with pH=4 at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com