Novel carbon-based material supporting spinel catalyst and preparation method thereof

A technology of carbon-based materials and catalysts, which is applied in the field of new-type carbon-based material-loaded spinel catalysts and its preparation, which can solve the problems of low efficiency and achieve uniform particle size, high purity, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

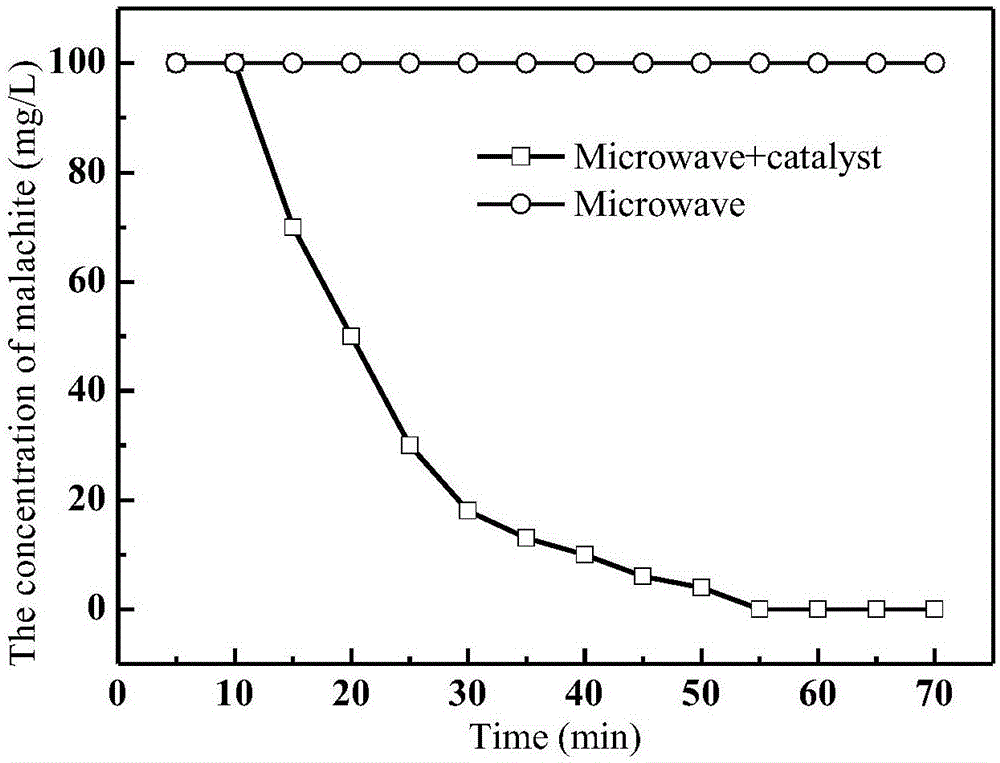

[0077] After acidifying 5g of activated coke with 3mol / L nitric acid at 75°C for 2h, immerse in 15mL of a mixed solution of 0.02mol / L ferric nitrate and 0.01mol / L nickel nitrate for 24h, and add 15mL of 0.1mol / L ammonia water, adjust the pH to 10, continue magnetic stirring for 2 hours, add to a hydrothermal kettle, react at 180°C for 24 hours, filter and dry, and calcinate at 500°C for 4 hours in a nitrogen atmosphere to prepare NiFe 2 o 4 / ASC catalyst, malachite green as water pollutant (100mg / L), 800W microwave catalytic removal rate see figure 1 .

Embodiment 2

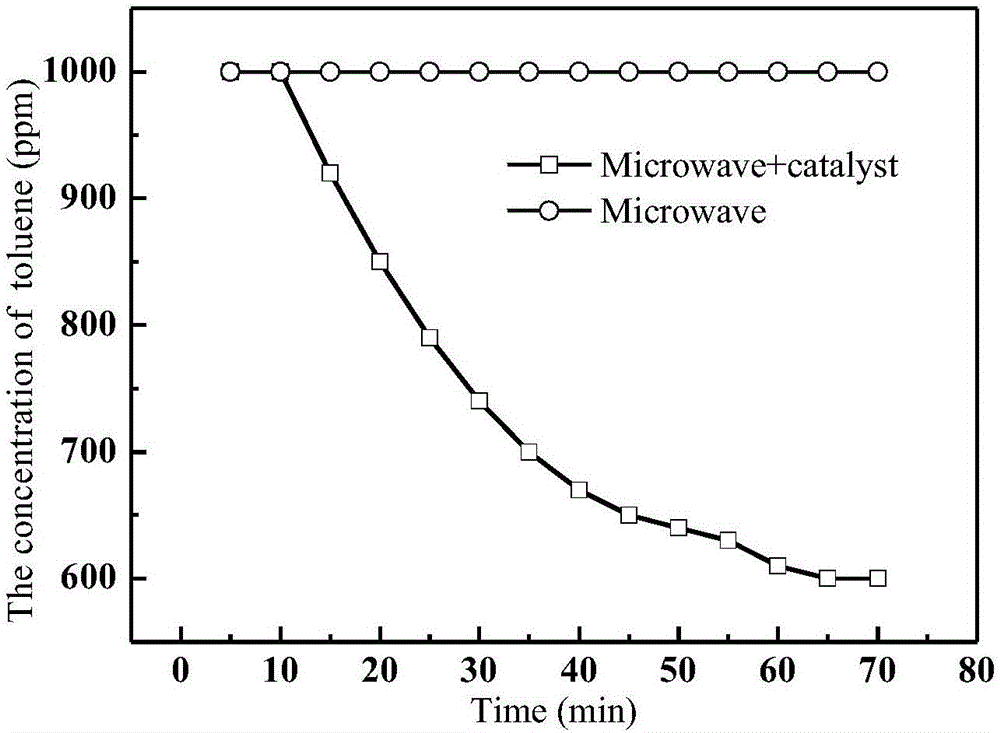

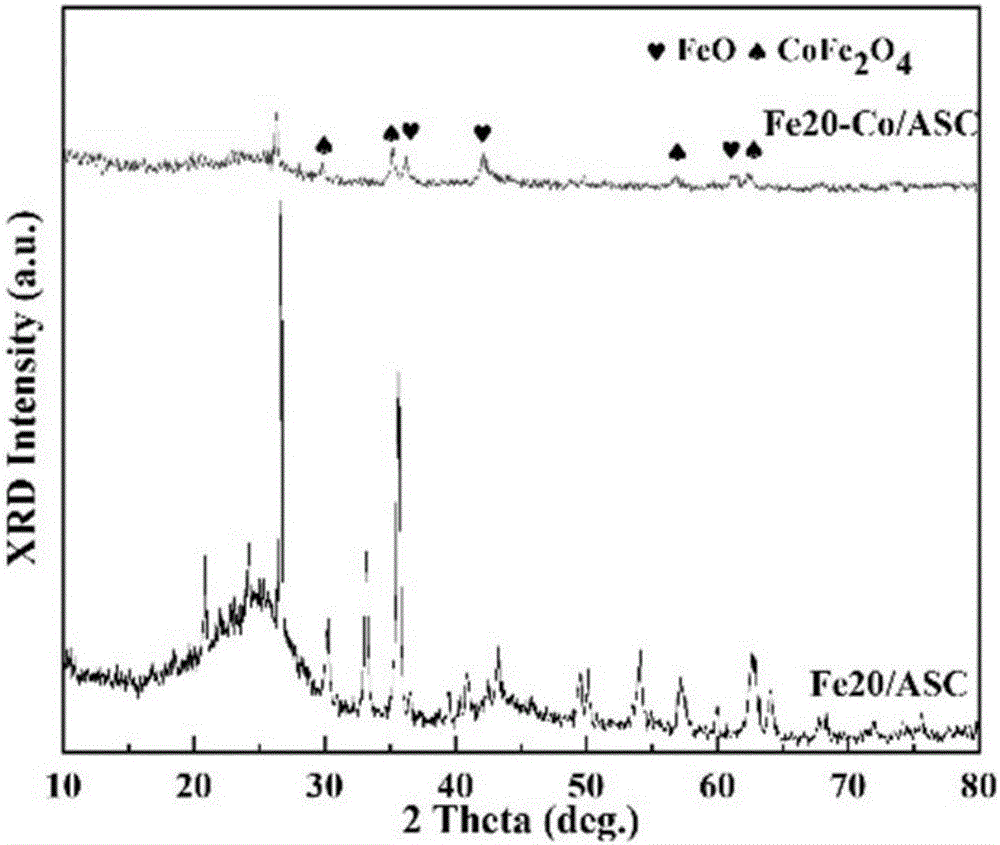

[0079] After acidifying 5g of activated coke with 3mol / L nitric acid at 80°C for 2h, immerse in 15mL of a mixed solution of 0.02mol / L ferric nitrate and 0.01mol / L cobalt nitrate for 24h, and add 15mL of 0.1mol / L ammonia water, adjust the pH to 10, continue magnetic stirring for 2 hours, add to a hydrothermal kettle, react at 180°C for 24 hours, filter and dry, and calcinate at 500°C for 4 hours in a nitrogen atmosphere to prepare CoFe 2 o 4 / ASC catalyst, the catalyst is characterized by XRD as image 3 shown, indicating that the spinel CoFe 2 o 4 Loaded on the surface of active coke, the toluene C 7 h 8 (Tar mold compound) as a gas pollutant (1000ppm), 800W microwave catalytic removal rate see figure 2 .

Embodiment 3

[0081] Put 5g of activated carbon into air with an oxygen volume concentration of 8vol.%, and after oxygen etching treatment at 300°C for 0.5h, immerse in 15mL of a mixed solution of 0.02mol / L cobalt nitrate and 0.01mol / L ferric nitrate for 24h , in the state of magnetic stirring, add 15mL sodium hydroxide solution, adjust the pH to 10, continue magnetic stirring for 2h, add a hydrothermal kettle, react at 180°C for 24h, filter and dry, calcinate at 500°C for 4h in a nitrogen atmosphere, and prepare FeCo 2 o 4 / AC Catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com