Preparing method of dithiocarbamic acid-based functionalized carbon nano tube

A technology of dithiocarbamic acid and carbon nanotubes, applied in the field of nanomaterials, can solve the problems of easy aggregation of carbon nanotubes, insufficient mechanical strength, and low specific surface area, and achieve good adsorption effect, good mechanical strength, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

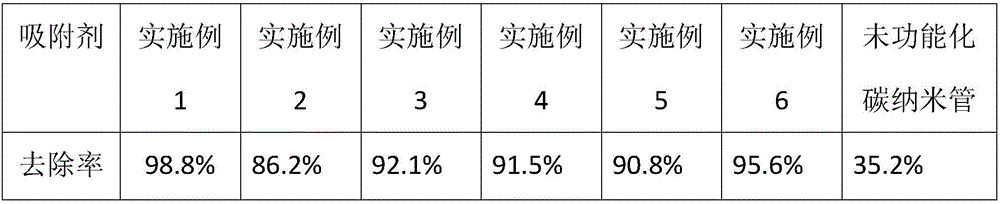

Examples

Embodiment 1

[0027] A method for preparing dithiocarbamate-based functionalized carbon nanotubes includes the following steps:

[0028] (1) Take 10 parts of multi-walled carbon nanotubes in a flask, add 1000 parts of mixed acid, where the mixed acid is made by mixing a 98% sulfuric acid solution with a mass concentration of 50% nitric acid solution, and the volume ratio is 3:1. The reaction was carried out at 80° C. for 3 hours under stirring. After the reaction was completed, the reaction was cooled, diluted with water, vacuum filtered, washed, and vacuum dried at 80° C. for 12 hours to obtain acid-treated carbon nanotubes.

[0029] (2) Take 10 parts of the above-mentioned acid-treated carbon nanotubes and disperse them in 1000 parts of organic solvent N,N-dimethylformamide (DMF), and add 500 parts of thionyl chloride (SOCl 2 ), and then turn on the temperature controller, make the reaction system reflux at 80° C. for 5 hours to remove the residual thionyl chloride. Add 100 parts of polyethyl...

Embodiment 2

[0032] A method for preparing dithiocarbamate-based functionalized carbon nanotubes includes the following steps:

[0033] (1) Take 10 parts of multi-walled carbon nanotubes in a flask, add 500 parts of mixed acid, where the mixed acid is made by mixing 80% sulfuric acid solution with mass concentration and 50% nitric acid solution with mass concentration, and the volume ratio is 3:1, react at 90°C for 5 hours with stirring, cool after the reaction, dilute with water, vacuum filter, wash, and dry at 50°C for 12 hours to obtain acid-treated carbon nanotubes.

[0034] (2) Take 10 parts of the above-mentioned acid-treated carbon nanotubes, disperse them in 500 parts of organic solvent N,N-dimethylformamide (DMF), and add 50 parts of thionyl chloride (SOCl 2 ), and then turn on the temperature controller to make the reaction system reflux at 65°C for 5 hours to remove the residual thionyl chloride. Add 50 parts of ethylenediamine to the above reaction system, reflux at 70°C for 3h, vac...

Embodiment 3

[0037] A method for preparing dithiocarbamate-based functionalized carbon nanotubes includes the following steps:

[0038] (1) Take 10 parts of multi-walled carbon nanotubes in a flask and add 700 parts of mixed acid, where the mixed acid is made by mixing a sulfuric acid solution with a mass concentration of 90% and a nitric acid solution with a mass concentration of 60%, and the volume ratio is 3:1, react at 80°C under stirring for 4h, cool after the reaction, dilute with water, vacuum filter, wash, and dry under vacuum at 60°C for 12h to obtain acid-treated carbon nanotubes.

[0039] (2) Take 10 parts of the above acid-treated carbon nanotubes and disperse them in 700 parts of organic solvent N,N’-dimethylacetamide DMAC, add 200 parts of thionyl chloride (SOCl 2 ), and then turn on the temperature controller, and make the reaction system reflux at 70°C for 3 hours to remove the residual thionyl chloride. Add 80 parts of cyclohexylamine to the above reaction system, reflux at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com