Resin composition for copper foil-clad base plate in high-frequency and high-speed field and application thereof

A technology of copper clad substrate and resin composition, which is applied in the direction of lamination, layered products, metal layered products, etc., can solve the problems of poor processability, insufficient resin fluidity, large molecular weight, etc., and achieve low loss factor, excellent Effect of low dielectric constant and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

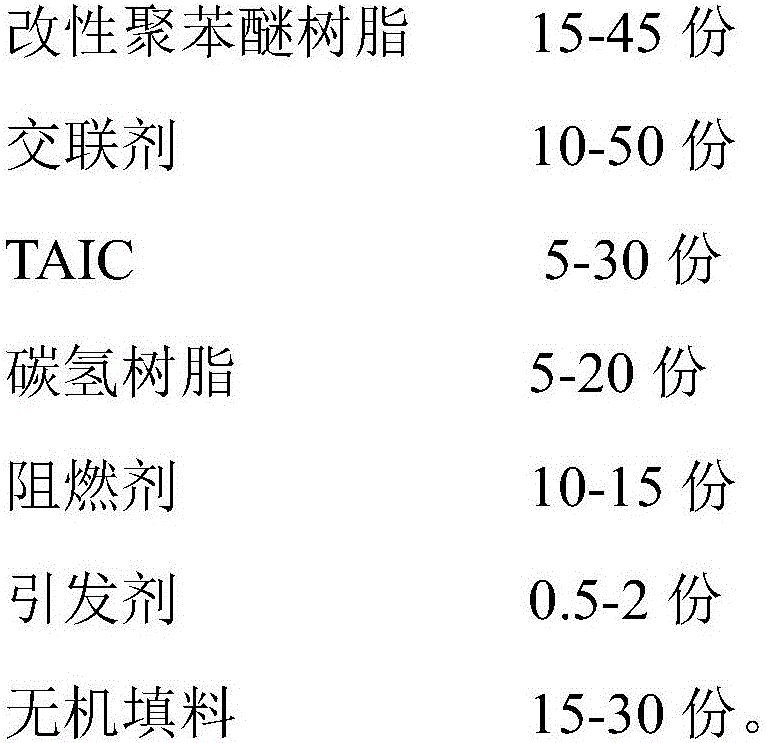

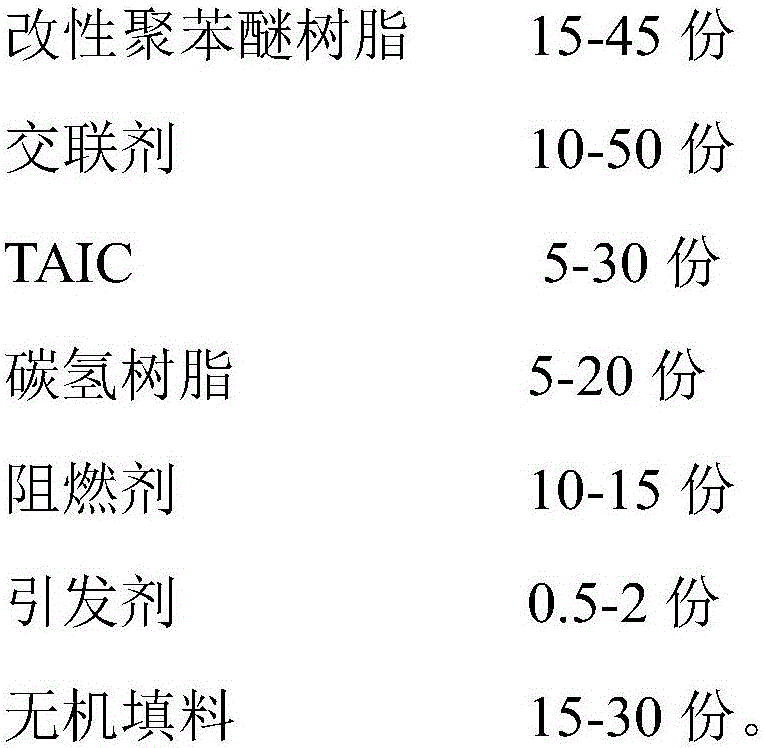

[0024] In this embodiment, a resin composition for copper-clad substrates in the high-frequency and high-speed field is prepared by stirring 65 wt% of active ingredients and 35 wt% of solvent (butanone) through a disperser, and the active ingredients include the following weight Parts of raw materials: 20 parts of terminal allyl polyphenylene ether (weight average molecular weight is 2000), 20 parts of styrene, 15 parts of TAIC, 5 parts of petroleum resin C5, 12 parts of decabromodiphenylethane, 1 part of di Cumene and 27 parts of microsilica.

[0025] Use 2116 glass fiber cloth to impregnate the above resin composition, and bake at 125°C for 190s to make a prepreg. The resin content of the prepreg was 50%, and the resin fluidity was 20%.

[0026] Take 6 pieces of prepreg and stack them up, with 1HZ electrolytic copper foil on both sides, then clamp them between two steel plates, place them in a vacuum press, and heat them at 200°C and 35kg / cm 2 Under the conditions of hot p...

Embodiment 2

[0028] In this embodiment, a resin composition for copper-clad substrates in the high-frequency and high-speed field is prepared by stirring 70wt% active ingredients and 30wt% solvent (butanone) through a disperser, and the active ingredients include the following weight Parts of raw materials: 15 parts of terminal allyl polyphenylene ether (weight average molecular weight is 2000), 25 parts of styrene, 10 parts of TAIC, 10 parts of petroleum resin C5, 12 parts of decabromodiphenylethane, 1 part of di Cumene and 27 parts of microsilica.

[0029] Use 2116 fiberglass cloth to impregnate the above resin composition, and bake at 125°C for 180s to make a prepreg. The resin content of the prepreg was 50%, and the resin fluidity was 20%.

[0030] Take 6 pieces of prepreg and stack them up, with 1HZ electrolytic copper foil on both sides, then clamp them between two steel plates, place them in a vacuum press, and heat them at 200°C and 35kg / cm 2 Under the conditions of hot pressing ...

Embodiment 3

[0032] In this embodiment, a resin composition for copper-clad substrates in the high-frequency and high-speed field is prepared by stirring 65 wt% of active ingredients and 35 wt% of solvent (butanone) through a disperser, and the active ingredients include the following weight Parts of raw materials: 25 parts of terminal allyl polyphenylene ether (weight average molecular weight is 2000), 10 parts of styrene, 20 parts of TAIC, 5 parts of petroleum resin C5, 12 parts of decabromodiphenylethane, 1 part of di Cumene and 27 parts of microsilica.

[0033] Use 2116 glass fiber cloth to impregnate the above resin composition, and bake at 125°C for 200s to make a prepreg. The resin content of the prepreg was 50%, and the resin fluidity was 20%.

[0034] Take 6 pieces of prepreg and stack them up, with 1HZ electrolytic copper foil on both sides, then clamp them between two steel plates, place them in a vacuum press, and heat them at 200°C and 35kg / cm 2 Under the conditions of hot p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com