Application of carbon dots in light conversion of agricultural production as agricultural light conversion material

A technology of carbon dots and light conversion, which is applied in the field of agricultural light conversion, can solve the problems of affecting the absorption of visible light by plants, the decrease of light transmittance of materials, and the large size of light conversion agents, so as to achieve stable luminescence performance, small size, increase yield and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of carbon dots uses an organic amine and organic acid system. The representative raw materials are silane coupling agent (KH-602) and citric acid. The synthesis method is solvothermal method, which is divided into the following three steps:

[0042] (1) Measure 100mL of KH-602 as a solvent into a 250mL autoclave, then add 10g of anhydrous citric acid, stir for 10min by magnetic force and mix evenly.

[0043] (2) The temperature was raised to 240° C. under the protective gas of nitrogen, and the reaction was carried out for 20 minutes. The color of the solution changed to brownish yellow and the reaction was stopped.

[0044] (3) The reacted product was washed three times with petroleum ether, and refrigerated in the refrigerator for subsequent use.

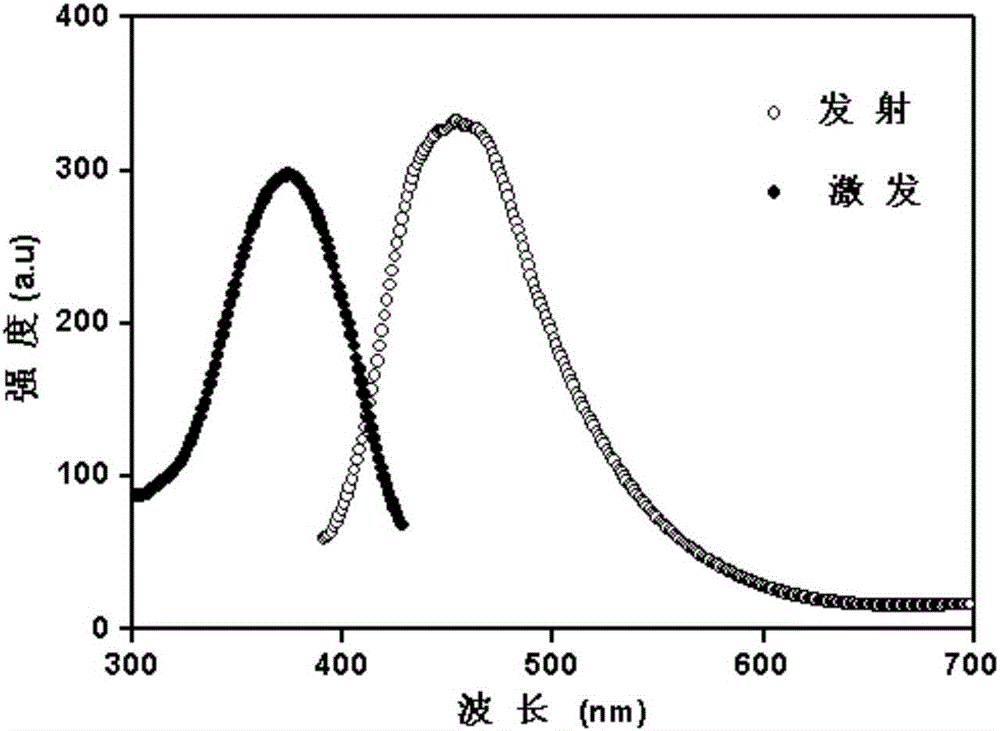

[0045] The resulting fluorescent carbon dots emit blue light under ultraviolet light, and the fluorescence spectrum is as follows: figure 1 shown. Depend on figure 1 It can be seen that fluorescent carbo...

Embodiment 2

[0047] The preparation of carbon dots adopts an organic amine and organic alcohol system. The raw materials are p-phenylenediamine and ethanol. The synthesis method is a solvothermal method, which is divided into the following three steps:

[0048] (1) Accurately weigh 0.3 g of p-phenylenediamine and 30 mL of ethanol as reactants, and mix them uniformly in the reactor by ultrasonic.

[0049] (2) Move the entire reaction kettle into a blast drying oven, set the reaction temperature to 180°C, and set the reaction time to 12 hours.

[0050] (3) Separating and purifying the cooled reactants to obtain fluorescent carbon dots.

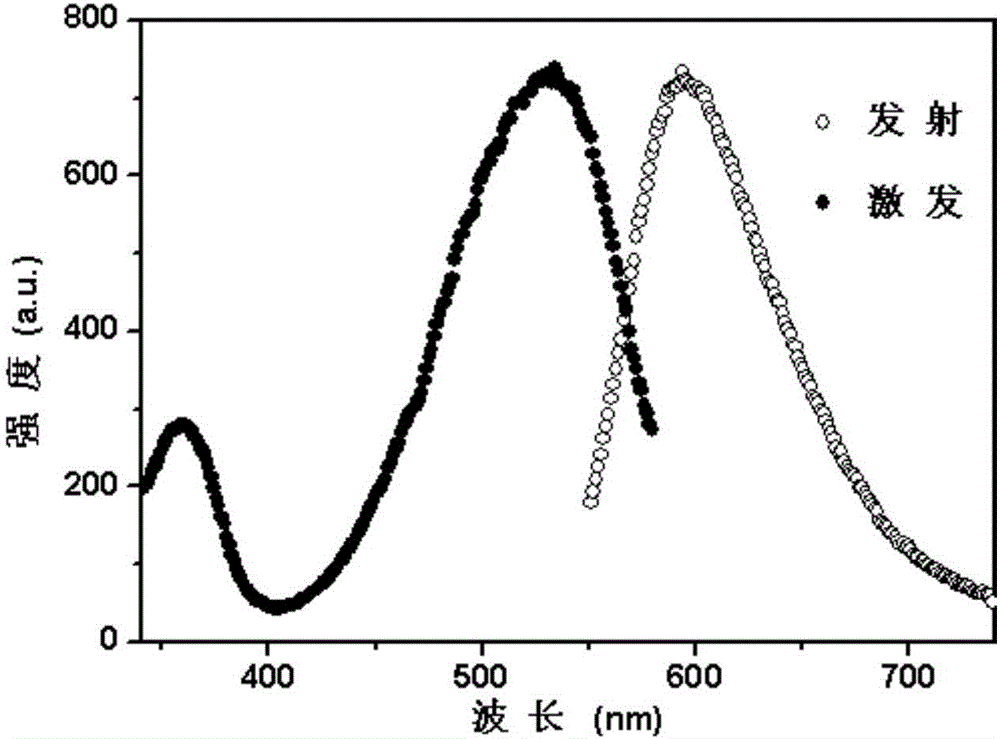

[0051] The resulting fluorescent carbon dots emit red light under ultraviolet light, and the fluorescence spectrum is as follows: image 3 shown. Depend on image 3 It can be seen that fluorescent carbon dots can effectively absorb ultraviolet light around 360nm and invalid yellow light around 520nm, and emit red light around 610nm, which effectively show...

Embodiment 3

[0053] The preparation of carbon dots uses an organic amine and organic alcohol system. The raw materials are ethylenediamine and polyvinyl alcohol. The synthesis method is a hydrothermal method, which is divided into the following four steps:

[0054](1) Weigh 1g of polyvinyl alcohol and dissolve it in 20mL of distilled water, then add 0.75mL of ethylenediamine and mix well in the reaction kettle.

[0055] (2) Put the whole reaction kettle into a blast drying oven, and react at 220° C. for 10 hours. After natural cooling, a brown suspension can be obtained.

[0056] (3) By adding excess acetone, the unreacted polyvinyl alcohol is precipitated and separated by centrifugal suction filtration.

[0057] (4) The carbon dot powder can be obtained through freeze-drying.

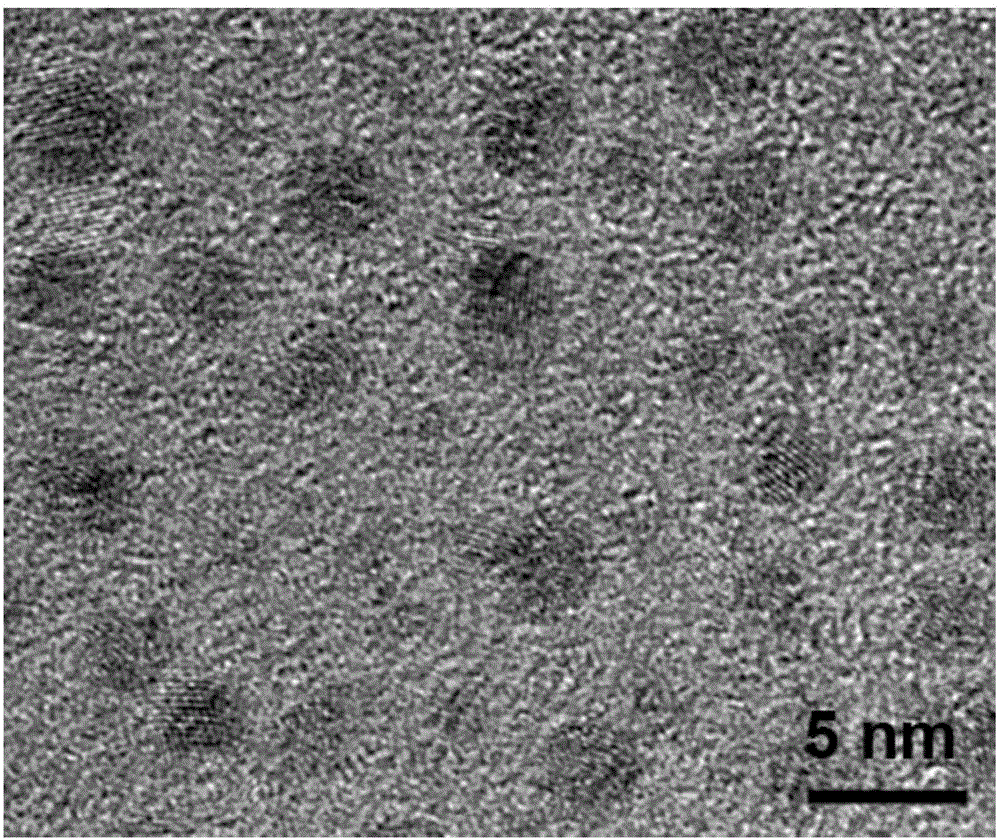

[0058] Observation by transmission electron microscope (such as Figure 4 ) prepared carbon dots, the particle size of the carbon dots is about 6nm, indicating that the particle size of the carbon dots is small ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com