Carbon dioxide soluble zwitterionic surfactant and preparation method thereof

A surfactant, carbon dioxide technology, applied in the preparation of ether from alkylene oxide, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high price, insoluble in water phase, low solubility of carbon dioxide, etc. It has the effect of solubility, low product price, good hydrophilic and carbon dioxide-friendly properties and resistance to hard water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

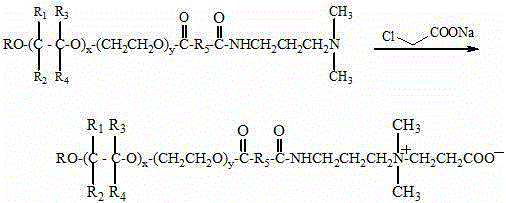

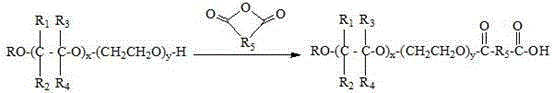

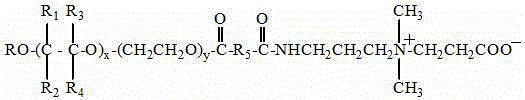

Method used

Image

Examples

Embodiment 1

[0034] The synthesis of embodiment 1 surfactant

[0035] The synthesis of alkyl polyoxyalkyl ether: add 20.0 g isooctyl alcohol and catalyst 1.0 g KOH in autoclave, with N 2 Replace the air in the kettle for 3 times, heat the kettle to 80°C, add 53.4g of propylene oxide after vacuum removal, heat to 160°C for ring-opening polymerization for 3 hours, then continue to add 13.5g of ethylene oxide to react for 2 hours, after the end Open the kettle to lower the temperature, and discharge the product to obtain the product.

[0036] Synthesis of alkyl polyoxyalkyl ether carboxylic acid: Add 56.6 g (0.10 mol) of alkyl polyoxyalkyl ether product and 10.0 g (0.1 mol) of solid succinic anhydride into a three-neck flask, and pass nitrogen gas at the reflux condenser Protect, stir and heat to 90°C. After 3 hours of reaction, the succinic anhydride solid disappears, and the product is obtained by cooling down.

[0037] Amidation reaction: Add 66.6 g (0.1 mol) of alkyl polyoxyalkyl ether ...

Embodiment 2-7

[0039] Examples 2-7 Solubility test of surfactants in carbon dioxide.

[0040] Take 0.15, 0.20, 0.25, 0.30, 0.35, and 0.40 g of the surfactant products in Example 1, respectively, and add them to a high-pressure reaction kettle with a glass window in sequence, feed carbon dioxide to 20 MPa, heat to 40°C, and fine-tune the pressure To 25.0 MPa, the supercritical carbon dioxide is 120.5 g at this time calculated by the volume of the reactor. Start the mechanical stirring and observe the dissolution of the solid surfactant.

[0041] Example Surfactant quality Surfactant concentration (wt%) Dissolution 2 0.15 0.12 Completely dissolved, clear and transparent 3 0.20 0.17 Completely dissolved, clear and transparent 4 0.25 0.21 Completely dissolved, clear and transparent 5 0.30 0.25 Completely dissolved, clear and transparent 6 0.35 0.29 Completely dissolved, clear and transparent 7 0.40 0.33 The solution is cloudy and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com